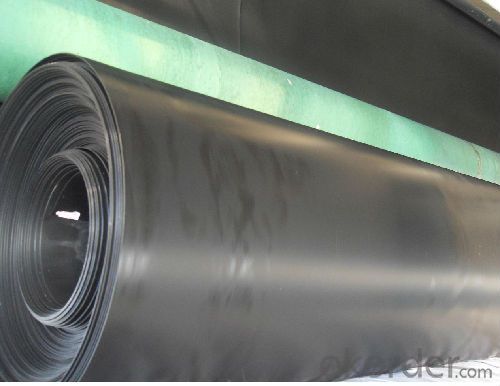

American Standard Smooth Geomembrana in HDPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description:

1.used in landfill caps

2. base liner applications under roads, railways,

3.as well as within various other containment structures such as dams, canals, ponds, rivers and lakes

Our product was proved as good physical and mechanic performance,

oil and salt, alkali and corrosion resistance, high and low temperature resistance, non-toxicity, long operational life, good waterproof, drainage, anti-seepage and damp proof effects.

2.Product Characteristic:

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

3.Product Specifications:

1.thickness : 0.1---3.0mm,

2.Length: 50 m -100 m ; width: 1 m -8 m ( according to customer needs )

3.Elongation at break:700%

4.Material: HDPE.

5.Color: Black or as you required

4.Reference Picture

- Q: which is more often used between the common membrane and the glass membrane static electricity?

- Ordinary film is easy to produce static electricity. Because the ordinary film is a layer of plastic film, the core material of the steel glass stick membrane is: Toughened glass. compared the two materials, the ordinary plastic film is easy to produce static electricity.

- Q: Is electrothermal?film safe?

- Electrothermal?film system has extremely high security, having no security risk, which is a very mature product. After testing by related departments, its insulation grade, voltage endurance capability, leakage current, flame resistance have reached the corresponding national standards.

- Q: How to maintain the paint film of solid wood floor?

- Use a soft towel to wipe and wax every year, it can maintain smooth and beautiful.

- Q: Reservoir, the dam foundation is weak, the dam earth membrane seepage control design, the geotechnical membrane in the dam before the need to extend long? Are there bases?

- Geotechnical membrane in the dam before the need to save about 2 meters in order to be used for the use of geotechnical membrane anchorage ditch

- Q: How to stick mobile phone film?

- 1. Clean the screen with BG cleaning cloth (or fiber soft cloth, glasses cloth) thoroughly. It is better to clean the screen indoors in a neat condition without air flow to reduce the influence of dust. If there is dust on the screen, bubbles will stay between the membrane and the screen which means the failure of sticking membrane. Membrane will become useless when there is dust between it and the screen which damages the silica gel layer of packaging film. 2. Wipe off the stubborn?dirt with BG dedusting paster. If there is stubborn?dirt remaining on the screen, clean the screen with dry cleaning cloth. Wet cloth should not be used. Dedusting paster can stick the dust. So it can be used to clean the screen. Stick dedusting paster back to the original backing paper after using it. Then the paster is recycled. 3. Check the membrane. Take the membrane out of the package. Do not tear off the release liner directly. Put it on the screen of the cellphone, check if the membrane is suitable. Make clear of the place to stick membrane. This will help in later steps. 4. Tear off the first release liner partly. Pay attention to not touch the part of protective membrane exposed with your finger. Each cellphone film is composed of three layers. The first and the last are release liners to protect the protective membrane sandwiched between them.

- Q: What are the specifications of moistureproof membranes?

- Common moistureproof membranes include wallpapers, coating layers, plywood. Professional moistureproof membranes are developed by water technology which are harmless to the human body and the environment for no volatilization of polluting gases. Comparing with the traditional oil alkyd varnish, it effectively protect the indoor environment.

- Q: How many square meters of geomembrane is a group?

- usually calculated by square meter or ton I feel deeply ashamed how much is the composite geo-membrane detection group? how much is geomembrane Let me give an answer

- Q: How to deal with the waterproof membrane on balcony?

- 1, Cleaning the base; 2, Leveling the base with cement mortar 3, brushing one layer of JS waterproof paint and paving one layer of non-woven fabric immediately. Then brushing a layer of JS waterproof paint again (it should be noted that walls should be flanged up for 300mm); 4, After the waterproof layer is totally dried, you can do the watyer conserving test for 24 hours; 5, After draining the water, you can lay the floor tile on it (it is better to leave the seams with the width of 5mm and brush structural adhesive in it).

- Q: What are the temperature resistance properties of geomembranes?

- Geomembranes have excellent temperature resistance properties, making them suitable for a wide range of applications. They can withstand both high and low temperatures, with some types capable of withstanding temperatures as low as -70°C and as high as 120°C. This temperature resistance allows geomembranes to maintain their integrity and performance in extreme weather conditions, making them ideal for applications such as containment of hazardous materials, landfill liners, and water storage systems.

- Q: Who exports geotechnical materials? I would like to ask how to calculate the loading quantity of geotextile, geomembrane and geogrid. For example, a 20 foot locker.

- It depends on the size of the material.

Send your message to us

American Standard Smooth Geomembrana in HDPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords