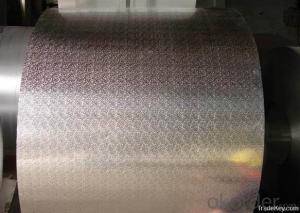

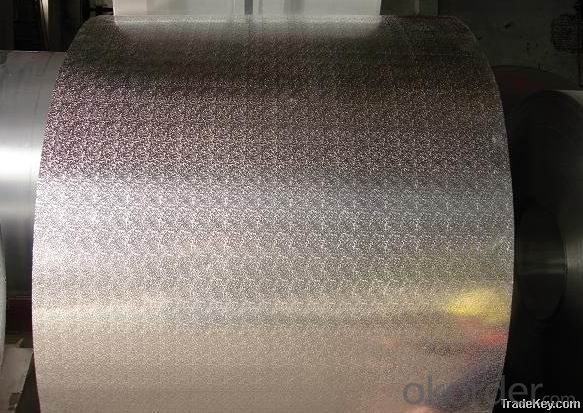

Aluminum Strip Coils 1060 1100 3003 5052 Embossed Aluminum Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Product | stucco checkered aluminum coil |

standard | ISO, GB, ASTM, AISI,etc |

certification | ISO |

thickness | 0.2-100mm |

width | 0.5-2m |

grade | 1000---7000 series |

colour | silver,golden,red, blue. etc |

surface treatment | polished ,anodized,mill finishing |

Application | machine,construction,decoration,fuiniture,industry,etc |

MOQ | 1 ton |

Delivery time | normally within 10-20 days after getting your deposits. |

Payment terms | L/C, T/T |

Supply ability | 5000 tons/month |

Packaging | 1.Export standard packaging, or according to the customer demands 2.with wooden pallets or film covered , in the containers. 3.The inner size of container is below: |

Features for Aluminum coil:

1) High flexibility

2) Excellent weather-proof durability

3) Anti-ultraviolet

4) High erosion resistance

5) Good mechanical processing performance

6) Stable color and gloss

Features for Aluminum coil:

1) High flexibility

2) Excellent weather-proof durability

3) Anti-ultraviolet

4) High erosion resistance

5) Good mechanical processing performance

6) Stable color and gloss

FAQ

Q: Do you have the CE, TUV, UL Certification?

A: We’ve already passed all the tests, and any certificate is available.

Q: Have you ever sold your products to companies in my country?

A: Of course, we have customers in all general PV markets, but I think we should expand our market share along with the market growth.

Q: How do you pack your products?

A: We have rich experience on how to pack to make sure the safety on shipment when it arrives at the destination.

Q: Can you do OEM for us?

A: Yes, we can.

Q: Can we visit your factory?

A: Surely, I will arrange the trip basing on your business schedule.

- Q: What should pay attention to transporting aluminum coil?

- You must ensure the good property of the aluminum coil.

- Q: What are the common alloys used in aluminum coil production?

- The common alloys used in aluminum coil production are 3003, 3105, 5052, and 6061.

- Q: Can aluminum coils be used for electrical transmission lines?

- Yes, aluminum coils can be used for electrical transmission lines.

- Q: What are the different packaging options available for aluminum coils?

- Customers have several packaging options to choose from for aluminum coils, depending on their specific needs and requirements. Some commonly used packaging options include: 1. Wooden crates: Sturdy wooden crates offer maximum protection for aluminum coils during transportation and storage. These crates are made of high-quality wood and designed to withstand rough handling, preventing coil damage. 2. Cardboard boxes: Smaller aluminum coils can be packaged in lightweight and cost-effective cardboard boxes. These boxes provide adequate protection against minor impacts and environmental factors. 3. Steel or aluminum skids: Aluminum coils can be placed on steel or aluminum skids for packaging. Skids provide a stable base and allow for easy handling using forklifts or pallet jacks. They are commonly used for larger coils or when transporting multiple coils together. 4. Stretch wrap: Stretch wrap is a popular choice for packaging aluminum coils. It offers excellent protection against dust, moisture, and scratches. The coils are tightly wrapped in plastic film, ensuring secure transportation. 5. Custom packaging: In certain cases, customers may require customized packaging solutions to meet specific requirements. This can include using protective covers, foam padding, or additional reinforcements to ensure safe handling and delivery of the aluminum coils. It is important to consider factors such as coil size, weight, transportation method, and intended use when choosing a packaging option. Working with a reputable packaging provider can help determine the most suitable packaging option for aluminum coils.

- Q: What are the maximum and minimum coil weights available?

- The maximum and minimum coil weights available can vary depending on the specific type of coil being referred to. In the context of electrical coils, such as those used in transformers or motors, the maximum and minimum coil weights are determined by factors such as the size and material of the wire used, the number of turns in the coil, and the intended application. These coils can range from very small and lightweight to much larger and heavier, with weight limits typically specified by manufacturers. For example, a small coil might have a maximum weight of a few grams, while a larger coil could weigh several kilograms. It is important to consult the specifications provided by the manufacturer or supplier of the specific coil to determine the maximum and minimum coil weights available for a particular application.

- Q: What are the various dimensions and specifications of aluminum coils available in the market?

- <p>Aluminum coils come in various sizes and specifications to cater to different industrial needs. Common sizes include thicknesses ranging from 0.005 to 0.5 inches (0.13 to 12.7 mm), widths from 1 to 72 inches (25 to 1829 mm), and lengths from 10 to 6000 feet (3 to 1829 meters). The specific dimensions can vary based on the manufacturer and the application, such as construction, automotive, or packaging. It's important to consult with suppliers for the exact sizes available for a particular project or application.</p>

- Q: How do aluminum coils compare to plastic coils in terms of durability?

- Aluminum coils generally offer superior durability compared to plastic coils. Aluminum is a highly durable material known for its strength and resistance to wear and tear. It can withstand heavy usage and is less likely to crack, break, or deform under pressure. On the other hand, plastic coils may be more prone to damage, especially when subjected to repetitive use or extreme temperatures. While plastic coils can be cost-effective and lightweight, they may not hold up as well over time. Therefore, if durability is a priority, aluminum coils are a better choice as they offer a longer lifespan and greater resistance to damage.

- Q: Are aluminum coils suitable for solar panel applications?

- Solar panel applications can benefit from the use of aluminum coils. This lightweight and highly conductive material offers several advantages. Firstly, aluminum coils effectively transfer and dissipate heat, playing a crucial role in maintaining solar panel efficiency and lifespan. By reducing the temperature of solar cells, aluminum's excellent thermal conductivity helps prevent overheating and potential damage. Furthermore, aluminum coils exhibit high resistance to corrosion, making them an ideal choice for outdoor solar panel installations. Given the exposure to various weather conditions like rain, snow, and humidity, solar panels are prone to corrosion and degradation. However, aluminum's natural oxide layer acts as a protective barrier, ensuring corrosion prevention and enhancing the durability of solar panels. Moreover, aluminum is a cost-effective material that is readily available and easy to manufacture. Additionally, its lightweight nature simplifies the transportation and installation of solar panels, resulting in reduced overall costs. To summarize, aluminum coils are a suitable option for solar panel applications due to their exceptional thermal conductivity, resistance to corrosion, durability, and cost-effectiveness.

- Q: I need to make aluminum powder that is fine! I don't have a mill to use or something like that. If I fill literally the whole coffee blender, will that get it fine? I want to make an ok amount of it. I tried to use sand paper which makes it as fine as I want it but takes a while of sanding.

- Dissolve it with an acid--vinegar's your best bet there unless you've got a way to get a hold of a stronger acid that'll do this quicker. Once all the aluminum's dissolved, put in some magnesium like you can get from one of those fire starting tools that's just a brick of magnesium with a spark strip on it. The magnesium will ionize and the aluminum will precipitate out of the solution. Add the magnesium in as small of individual quantities as you can, too, to keep the size of individual precipitate particles down. Also, I recommend neutralizing the acid before adding the magnesium in case there's any acidity left--baking soda will work fine and doesn't stink like ammonia. If the solution's too acidic when you add the magnesium, the magnesium will go for the acid instead of the aluminum.

- Q: How are aluminum coils coated or treated for specific applications?

- Aluminum coils are coated or treated for specific applications through various processes such as painting, anodizing, and thermal spraying. These treatments enhance the coil's durability, corrosion resistance, and aesthetic appeal. For example, painting involves applying a protective coating of paint to the aluminum surface, while anodizing involves creating a layer of oxide on the surface to improve resistance to wear and corrosion. Thermal spraying is another method where a coating material is sprayed onto the surface using heat, providing additional protection and specific functional properties.

Send your message to us

Aluminum Strip Coils 1060 1100 3003 5052 Embossed Aluminum Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords