Aluminum Skin Sheets - 0.4mm Alloy Aluminum Sheet 3003 H14 from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

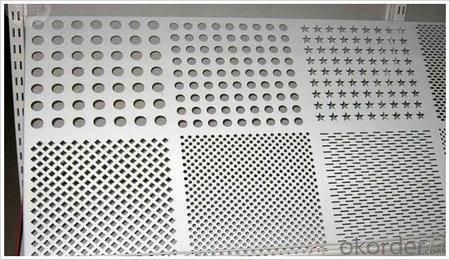

0.4mm alloy aluminum sheets 3003 H14

Alloy:3003

Temper: O H H12 H14 H18 H24

Thickness(mm):0.2-350mm

Width(mm):200-2300

Length(mm):800-13000

Delivery lead time: 20-25 days

Packing: wooden/veneer pallet, wooden/veneer case

Unit Price/Payment: FOB, CIF, CFR

Payment term: TT, LC at sight, Westen union

Country of origin: China

Certificate approved: ISO9001, SGS

MOQ: 2.0-2.5 metric ton per size

3003 Chemistry Composition | |||||||||

Element | Si | Fe | Cu | Mn | Mg | Cr | Ti | Zn | Al |

Standard Value | 0.6 | 0.7 | 0.05~0.20 | 1.0~ 1.5 | --- | --- | ---- | 0.10 | remainder |

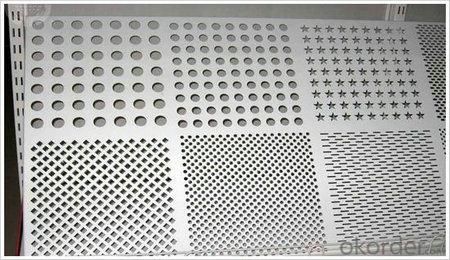

3003 Aluminum is alloyed with 1.20% manganese, which increases the strength of 3003 over commercially pure aluminum (1100 series). 3003 has excellent workability, weldability, and good corrosion resistance. It is used for drawing, forming, spinning, fuel tanks, sheet metal works and other applications that require moderate strength for an aluminum with good weldability. H14 designates the temper, and means that 3003 has been strain hardened and partially annealed. In this condition, 3003 can be easily formed. Embossing or debossing 3003 in this temper should not strain or crack the plate.

The aluminum3003 ALUMINUM TREAD PLATE - Often referred to as diamond plate, it has the same properties of 3003H14, while excellent at resisting corrosion, and strong for light weight aluminum applications. The diamond trend pattern is slip-resistant and cosmetically appealing.

Applications:

· Cat Walks

· Heat Exchangers

· Food and Chemical handling equipment

· Truck and Trailer Roofing

· Floor Panels

Packaging & Delivery

| Packaging Details: | Export standard seaworthy fumigated wooden pallet only |

| Delivery Detail: | 15days |

- Q: Where is the difference between the 5052 aluminum plate and the 1060 Aluminum plate?

- Composition and properties are not the same, first of all, 5052 belong to the alloy (aluminum magnesium) aluminum, aluminum content of about 95%, the magnesium content of about 4%, there are some other trace metals, 1060 pure aluminum (aluminum content of 99.6%, the balance of other metal elements); followed by mechanical propertiesTwo aluminum in the same state, 5052 to 1060 in hardness, elongation, tensile strength and so on are not the same. Specific depends on what state (H14, H32, H24, O state, etc.); finally, because the price of different components determine the price is different, the price is usually 5052 higher than 1060.

- Q: This question asks about the impact of aluminum sheets on the quality of air inside a building.

- <p>Aluminum sheets themselves do not directly affect indoor air quality in a building. They are inert materials that do not emit harmful gases or particles. However, the installation process may involve adhesives or sealants that could release volatile organic compounds (VOCs) temporarily, which can affect air quality. Proper ventilation during installation and after can mitigate this. Additionally, aluminum sheets can contribute to better air quality by providing a barrier against moisture and mold growth, which can be a concern with other building materials.</p>

- Q: Are aluminum sheets resistant to saltwater corrosion?

- Yes, aluminum sheets are highly resistant to saltwater corrosion.

- Q: Explain the similarities and differences in the properties of aluminum metal, Al(s) and aluminum oxide (a salt) Al203(s) in terms of the particles and forces present.. thanks doods!

- Aluminum metal is not found in nature, only aluminum oxide is in the mine or ground and they have to separate it from the oxidation to make a useful metal.

- Q: Can aluminum sheets be welded or soldered?

- Yes, aluminum sheets can be welded or soldered. However, the process for each differs significantly. Welding aluminum typically involves using a TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding process, which requires a high heat source and a filler material to join the sheets together. The process can be more challenging compared to welding steel due to aluminum's high thermal conductivity and lower melting point. Soldering aluminum, on the other hand, is a process that involves using a low-temperature solder and flux to bond the sheets together. Specialized solders, such as aluminum solder or solder with a high percentage of tin, are typically used. Soldering aluminum is generally less common and more difficult compared to soldering other metals due to aluminum's oxide layer, which can prevent proper adhesion. In summary, while both welding and soldering can be used to join aluminum sheets together, welding is the more commonly used method due to its stronger and more durable results. Soldering aluminum can be more challenging due to the need for specialized solders and the presence of the oxide layer.

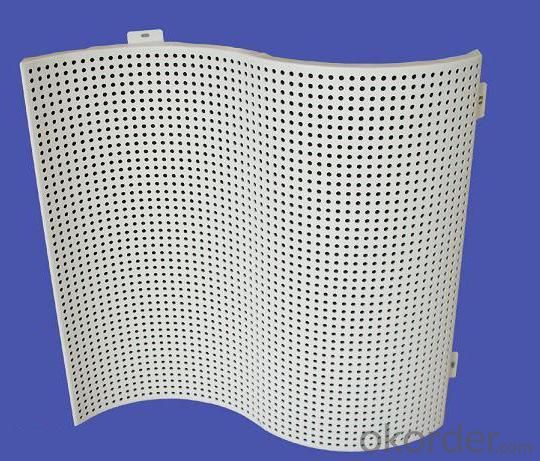

- Q: Can aluminum sheets be used for cladding?

- Indeed, cladding can certainly make use of aluminum sheets. The utilization of aluminum as a cladding material is widespread owing to its plethora of advantageous attributes. Its lightweight nature, durability, resistance to corrosion, exceptional thermal and acoustic insulation properties all contribute to its popularity. Furthermore, aluminum is highly malleable, granting designers a wide array of possibilities. The application of aluminum cladding is prevalent in both residential and commercial constructions, serving to provide protection, enhance aesthetic appeal, and boost energy efficiency.

- Q: Can the aluminum sheets be used for manufacturing audio amplifier cases?

- Certainly, audio amplifier cases can be manufactured using aluminum sheets. The utilization of aluminum as casing material in audio equipment is highly favored owing to its remarkable combination of lightweight and resilient characteristics. It offers exceptional heat dispersion, a critical aspect for audio amplifiers that generate heat while in operation. Additionally, aluminum can be effortlessly machined and shaped into diverse forms, facilitating customization and aesthetic considerations in the design of the amplifier case. In conclusion, aluminum sheets are a fitting choice of material for the production of audio amplifier cases.

- Q: Is this aluminium plate ceiling dark keel or bright keel?

- I see you're a layman...... Where is the ceiling keel now?.... Now they are made of dark keel, so it's better to look at comfort, and we need to go through the lines and some pipes

- Q: Can aluminum sheets be used for heat lamps?

- Yes, aluminum sheets can be used for heat lamps. Aluminum is a good conductor of heat, meaning it can effectively transfer and distribute heat. This property makes it suitable for use in heat lamps, which require efficient heat distribution to effectively warm objects or spaces. Additionally, aluminum is lightweight, durable, and has a high melting point, which makes it a practical choice for heat lamp applications.

- Q: Can aluminum sheets be used for modular construction?

- Yes, aluminum sheets can be used for modular construction. Aluminum is lightweight, durable, and corrosion-resistant, making it an excellent choice for modular construction applications. It is commonly used for building facades, roofing, and structural components in modular construction due to its strength-to-weight ratio and ease of installation.

Send your message to us

Aluminum Skin Sheets - 0.4mm Alloy Aluminum Sheet 3003 H14 from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords