Aluminum Siding Strips - AL+PET+LDPE Insulation and EPE Foam Foil Mylar Film for Heat Seal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Features high peel adhesion with good tack, temperature and aging resistance, and water vapor resistance

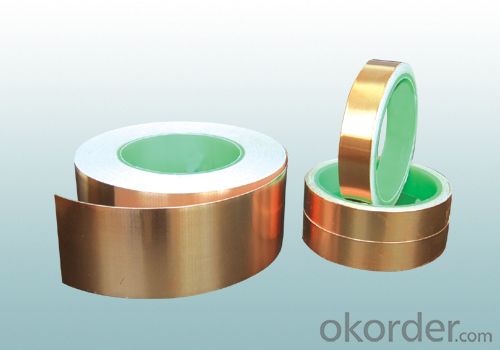

Aluminum Foil Tape Features:

1) High tensile strength aluminum foil made from special aluminum

alloy, coated with aggressive solvent-based acrylic adhesive,

which provides high peel adhesion and quick sticking

2) Designed for sealing joints and seams of foil jacketing in

air-conditioning duct work

Specifications:

1) Foil thickness: 18, 22, 26μ

2) Roll width: 48, 50, 60, 72, 75, 96, 100mm

3) Roll length: 27, 30, 45, 50m

4) Log roll: 1.2 x 45m, 1.2 x 50m

5) Jumbo roll: 1.2 x 1200m, 1.2 x 1000m

Inner packing:

Cut roll: printed core and shrink wrapping

Log roll: cardboard wrapping

Jumbo roll: plastic film + corrugated board wrapping

Outer packing:

Cut roll: carton

Log roll: carton + pallet / wooden case

Jumbo roll: wooden case

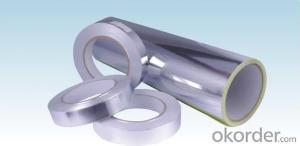

Aluminum Foil Mylar can be used to shield and isolate interference of electromagnetic waves and radio waves, etc

The Al-PET foil we made of aluminum foil and PET or colorized PET by scientifically processing. The width is between 5mm-1000mm; and the thickness is more than 0.025mm. They are used in electromagnetic shielding and electrical cables and wires shielding fields, etc.

Index of Al-PET foil:

Sequence No. | Index Character | Unit | Index |

1 | Thickness | mm | 0.025±0.00025 |

2 | Aluminum thickness | mm | 0.01±0.001 |

3 | PET thickness | mm | 0.012 ± 0.02 |

4 | Tensile strength | N/mm2 | ≥ 100 |

5 | Ultimate elongation | % | ≥ 20 |

6 | Bond strength | N/25mm | ≥ 8.0 |

7 | Aging resistance | Be immersed in 70±2°C water for 7days | Non-delaminating |

8 | Oxidative stability | - | excellent |

- Q: What benefits does aluminum offer as a roofing material compared to other metals?

- <p>Aluminum strips for metal roofing offer several advantages over other types of metal roofing. They are lightweight and easy to install, reducing labor costs. Aluminum is highly resistant to corrosion, ensuring a long lifespan and low maintenance. It also reflects heat well, which can help keep buildings cooler and reduce energy costs. Additionally, aluminum is recyclable and can be produced in various colors, making it an environmentally friendly and aesthetically versatile choice.</p>

- Q: What specific tools or equipment are necessary to install aluminum strips?

- <p>To install aluminum strips, you generally need a few basic tools. A measuring tape is essential for accurate placement. A utility knife or a metal cutting tool is necessary for cutting the strips to the correct length. A level is crucial to ensure the strips are straight. A rubber mallet or a hammer can be used to secure the strips in place. Adhesive, such as construction adhesive or double-sided tape, is often required to attach the strips. Safety equipment like gloves and safety goggles should be worn to protect against sharp edges and debris.</p>

- Q: Is it possible to use aluminum strips for exterior trim applications?

- <p>Yes, aluminum strips can be used for exterior trim. They are lightweight, durable, and resistant to corrosion, making them suitable for outdoor use. Aluminum trims are low maintenance and can withstand various weather conditions without rusting. They are also available in a variety of colors and finishes, allowing for flexibility in design. However, it's important to ensure proper installation and use high-quality materials to guarantee longevity and performance.</p>

- Q: What specific considerations or precautions should be taken when using aluminum strips in extremely cold weather conditions?

- <p>In cold climates, aluminum strips may become more brittle and susceptible to cracking or breaking. It's important to use aluminum alloys specifically designed for low-temperature applications to maintain strength and ductility. Proper installation is crucial, ensuring that strips are not overly stressed or subjected to sharp bends that could lead to fractures. Additionally, it's advisable to check for any condensation or ice buildup that could cause slippage or damage. Regular inspections are recommended to identify and address any issues before they become critical.</p>

- Q: Is there any health risk associated with the use of aluminum in food packaging?

- <p>There are some concerns about the use of aluminum in food packaging due to its potential to leach into food, especially when in contact with acidic foods. Aluminum exposure has been linked to neurological disorders, including Alzheimer's disease, although the evidence is not conclusive. The World Health Organization states that while there is no clear risk from dietary aluminum, further research is needed. It's important to note that aluminum is naturally present in many foods and drinking water, and the body can only absorb a small amount of aluminum from food packaging. Most aluminum exposure comes from natural sources, not from packaging.</p>

- Q: What are the specific types of aluminum strips that are frequently utilized in the construction industry?

- <p>Yes, there are several special types of aluminum strips commonly used in construction. These include aluminum flashing strips for waterproofing and sealing, aluminum trim strips for finishing edges and corners, and aluminum heat sinks for heat dissipation in electrical installations. Additionally, aluminum strips are used in curtain wall systems, window frames, and as reinforcement in concrete structures. The choice of aluminum strip depends on the specific requirements of the construction project, such as strength, durability, and resistance to corrosion.</p>

- Q: What are the cost differences between aluminum and aluminum strips?

- <p>Aluminum and aluminum strips are both made from the same base material, but their costs can differ due to several factors. Aluminum strips are typically more expensive than bulk aluminum due to the additional processing and manufacturing steps involved in creating them. These steps include rolling, cutting, and sometimes surface treatments, which add to the cost. Additionally, aluminum strips often have tighter tolerances and specific dimensions, which can also increase their price. However, the exact cost difference can vary based on factors such as market prices for aluminum, the complexity of the strip's specifications, and the quantity purchased.</p>

- Q: Is it possible to use aluminum strips as a roofing material in regions with cold weather conditions?

- <p>Yes, aluminum strips can be used for roofing in cold climates. Aluminum is a durable and lightweight material that is resistant to corrosion and weathering, making it suitable for various climates, including cold ones. It doesn't rust and can withstand heavy snow loads. However, it's important to consider the thermal properties of aluminum, as it conducts heat and cold efficiently, which may necessitate additional insulation to maintain the desired indoor temperature. Additionally, proper installation and underlayment are crucial to prevent moisture and heat loss.</p>

- Q: What effect does the aluminum pulley bring to the belt?

- Belt pulley with aluminum, absolutely assured, at present most of the design belt pulley, all with aluminum

- Q: This question asks about the impact of aluminum strips on the thermal insulation properties of a building.

- <p>Aluminum strips can significantly affect the insulation of a building by reflecting heat and light, reducing the amount of heat that is absorbed by the building's structure. This reflective property helps to keep the interior cooler in summer and can reduce the load on air conditioning systems. However, if not properly insulated, aluminum strips can also lead to heat loss in winter, as they can reflect heat back out of the building. Proper installation with insulation materials can maximize the benefits of aluminum strips in maintaining a comfortable indoor temperature while conserving energy.</p>

Send your message to us

Aluminum Siding Strips - AL+PET+LDPE Insulation and EPE Foam Foil Mylar Film for Heat Seal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords