APV 25 Aluminum Coil - Aluminum Rolls Sizes in All Kinds Available

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Rolls Sizes in All Kinds Available

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Aluminum Rolls Sizes in All Kinds Available

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Rolls Sizes in All Kinds Available

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

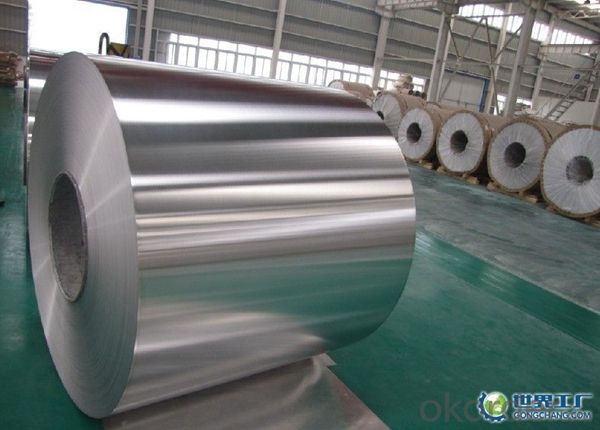

5. Image of Aluminum Rolls Sizes in All Kinds Available

6. Package and shipping of Aluminum Rolls Sizes in All Kinds Available

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the maximum temperature resistance of aluminum coils?

- The maximum temperature resistance of aluminum coils can vary depending on their specific alloy composition and application. However, in general, aluminum coils can withstand temperatures up to around 600 degrees Fahrenheit (315 degrees Celsius) before their structural integrity and performance may be compromised.

- Q: What are the best rust-proof coils? Please tell me the model and manufacturer in Shangdong. Thank you.

- 3003 aluminum coil, AL-Mn series alloy, is the most widely used rust-proof aluminum with the density being 2.73. It is applicable to insulation projects such as pipe insulation, packaging, machine parts, refrigerator, air conditioning and ventilation pipes and other wet environment.

- Q: The export aluminum volume is CIF. If there is no insurance policy, how will the customs premium be collected?

- The customs will not charge your premium the premium you can write but if you are a refund if there will be some impact because of the tax rebate minus the freight and insurance premium so you consider the premium but you can write less Never mind if you need shipping or shipping insurance declaration business can contact me oh

- Q: Are aluminum coils suitable for electrical conductors?

- Aluminum coils, indeed, prove to be suitable for electrical conductors. Due to its remarkable electrical conductivity, aluminum has become a widely utilized material in the electrical industry. It possesses approximately 61% conductivity in comparison to copper, the utmost commonly employed metal for electrical conductors. Lightweight, cost-effective, and possessing good thermal conductivity, aluminum coils have become a favored selection for a range of electrical applications. Nonetheless, it is noteworthy that aluminum has a lower tensile strength than copper, thus potentially demanding a larger cross-sectional area to attain an equivalent level of current carrying capacity. Furthermore, to prevent oxidation and guarantee efficient electrical conductivity in aluminum coils, it is imperative to employ proper insulation and connectors.

- Q: This question asks for the current prices of aluminum coil in various regions around the world.

- <p>The price of aluminum coil can vary significantly based on factors such as market demand, supply, transportation costs, and regional economic conditions. Prices are typically quoted per metric ton and are influenced by the London Metal Exchange (LME) and regional metal exchanges. For the most accurate and up-to-date prices, it's best to consult with local metal suppliers or check online commodity trading platforms. Prices can change daily, so real-time data is essential for making informed decisions.</p>

- Q: What are the different pre-treatment methods for aluminum coils?

- Some of the different pre-treatment methods for aluminum coils include cleaning, degreasing, etching, and phosphating. Cleaning removes dirt, dust, and other impurities from the surface of the coil. Degreasing eliminates oils and greases that may be present. Etching creates a rough surface on the aluminum, which helps in improving adhesion for subsequent coatings. Phosphating involves applying a phosphate coating to enhance corrosion resistance and improve paint adhesion. These pre-treatment methods ensure that the aluminum coils are properly prepared before any further processing or coating.

- Q: This question asks about the environmental impact of aluminum coils, which are commonly used in various industries.

- <p>Aluminum coils have both positive and negative environmental impacts. On the positive side, aluminum is highly recyclable, and its use in coils reduces the need for raw material extraction, thus conserving natural resources. The recycling process also consumes less energy compared to primary aluminum production, reducing greenhouse gas emissions. However, the production of aluminum coils involves energy-intensive processes that can contribute to carbon emissions. Additionally, if not properly managed, the waste from aluminum production can pollute water bodies and soil. Overall, the environmental impact depends on the balance between recycling and production practices, as well as waste management.</p>

- Q: How do aluminum coils contribute to the electrical conductivity of products?

- Aluminum coils are widely used in electrical applications due to their excellent conductivity properties. The electrical conductivity of aluminum is high, making it an ideal material for transmitting and distributing electrical power. When aluminum coils are used in products, they facilitate the flow of electric current. Aluminum has a low resistance to the flow of electricity, allowing for efficient transmission of electrical energy. This low resistance ensures minimal power loss during transmission, which is critical in maintaining the efficiency of electrical systems. Additionally, aluminum coils have a high thermal conductivity, allowing them to quickly dissipate heat generated during the transmission of electrical current. This is crucial in preventing overheating and maintaining the stability and longevity of electrical products. The lightweight nature of aluminum also contributes to its suitability in electrical applications. Its low density makes it easier to handle and install, reducing the overall weight of products and making them more portable. Overall, aluminum coils play a significant role in enhancing the electrical conductivity of products. Their high conductivity, low resistance, and excellent thermal properties make them a preferred choice in a wide range of electrical applications, including power transmission lines, electrical cables, motors, transformers, and other electrical devices.

- Q: I have aluminum windows that have to be replaced due to bad thermopanes - there is accumulated grime and humidity in between the panes. Is it possible to buy individual custom-sized replacements or do I have to get all new windows and frames? Any referrals would be helpful.

- If you want to replace them, I would start at a local home improvement store-- they all carry the major brands and there are tax incentives now for replacing windows.

- Q: Explain the differences between aluminum coils and iron coils, including their properties and applications.

- <p>Aluminum coils and iron coils differ in material composition, weight, strength, and applications. Aluminum coils are made of aluminum, a lightweight, corrosion-resistant metal, while iron coils are made from iron, which is heavier and more prone to rust. Aluminum coils have a lower density, making them ideal for applications where weight is a concern, such as in construction or automotive industries. They also have excellent electrical and thermal conductivity. Iron coils, on the other hand, are stronger and more durable, making them suitable for heavy-duty applications like construction reinforcement and machinery parts. Iron is also magnetic, which is an advantage in certain applications. However, iron is more susceptible to corrosion and requires protective coatings or treatments to extend its lifespan.</p>

Send your message to us

APV 25 Aluminum Coil - Aluminum Rolls Sizes in All Kinds Available

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords