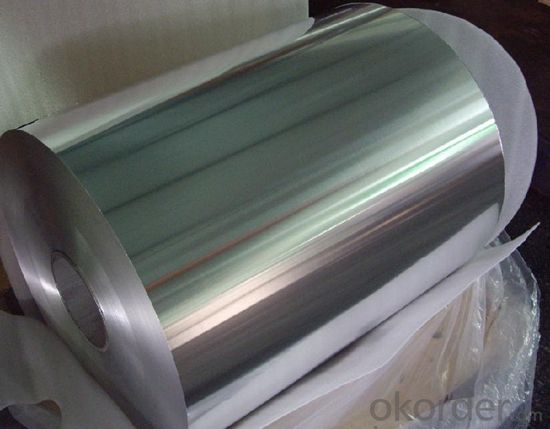

Aluminum Prepainted Aluminum Coil for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Grade:

5000 Series

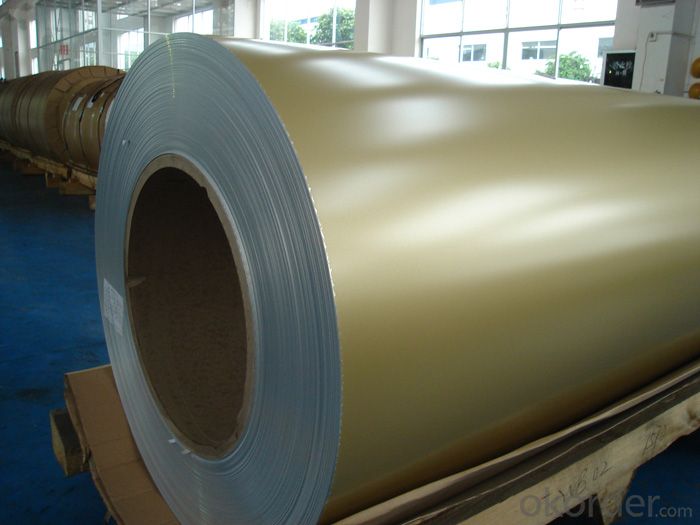

Surface Treatment:

Color Coated

Shape:

Rectangular

Temper:

T3-T8

Application:

Decorations

1. Grade

| Series: | 1100 etc. |

| Series: | 3003 3004 3005 etc. |

| Series: | 5006, 5052 |

| Series: | 8011 etc. |

2. Thickness

| Plate Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

| Coil Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

3. Colored aluminum foil Technical Data Of colorful coated aluminum coil :

| Item | Test Item | Standard | National Standard | Test Result |

| 1 | Color Difference | ECCA T3 | Delter E≤2.0 | Delter E≤1.0 |

| 2 | Gloss Difference | ECCA T2 | ≤10 | ≤5 |

| 3 | Coating Thickness | ECCA T1 | Two coating Min 23 mircron | ≥25 micron |

| Three coating Min 30 micron | ≥34 micron | |||

| 4 | Pencil Hardness | ASTM D3363 | ≥HB | HB |

| 5 | T-Bend | ASTM D4145 | ≤2T | ≤2T |

| 6 | Adhesion | ASTM D3359 | Grade 0 | Grade 0 |

| 7 | Impact | ASTM D2794 | ≤50kg.cm | ≤50kg.cm |

| 8 | Boiling Water Resistance | GB/T17748 | 2hr no change | 4hr no change |

| 9 | Slovent Resistance | ASTM D2248 | 200 times paint remaining | 500 times paint remaining |

| 10 | Acidity Resistance | ASTM D1308 | 5% HCL 24hrs no change | no change |

| 11 | Alkali Resistance | ASTM D1308 | 5% NAOH 24hrs Delter E≤2.0 | no change |

| 12 | Nitric Acid Resistance | AAMA620 | Delter E<5.0 | Delter E<5.0 |

| 13 | Oil Resistance | ASTM D1308 | 20# oil 24hrs no change | no change |

| 14 | Salt Spray Resistance | ASTM B117 | 4000hrs≤Grade 1 | no change |

| 15 | Abrasion Resistance | ASTM D968 | ≥5L/Micron | ≥5L/Micron |

| 16 | Contamination Resistance | GB/T9780 | ≤5% | <5% |

| 17 | Color Resistance | GB/T16259 | 4000hrs Delter E≤4.0 | 4000hrs Delter E≤3.0 |

| 18 | Gloss Losing Level | 4000hrs Delter E≤Grade 2 | 4000hrs Delter E≤Grade 2 | |

| 19 | Chalking | 4000hrs no change | 4000hrs no change |

- Q: Is it possible to utilize aluminum as a material for automotive construction?

- <p>Yes, aluminum is commonly used in cars. It is valued for its lightweight properties, which can improve fuel efficiency and reduce emissions. Aluminum is used in various parts of a vehicle, including engine components, body panels, and suspension systems. Its high strength-to-weight ratio and resistance to corrosion make it an ideal material for automotive applications.</p>

- Q: Is it possible to utilize aluminum in the construction of automobiles?

- <p>Yes, aluminum is widely used in automobiles due to its lightweight and high strength properties. It is commonly found in engine components, body panels, and wheels. Aluminum helps reduce the overall weight of the vehicle, which can improve fuel efficiency and reduce emissions. Additionally, it is resistant to corrosion and can be easily recycled, making it an environmentally friendly choice.</p>

- Q: This question asks about the environmental effects caused by the extraction and processing of aluminum.

- <p>The environmental impacts of mining and processing aluminum are significant. Mining can lead to deforestation and habitat destruction, affecting biodiversity. The process of bauxite extraction releases large amounts of greenhouse gases, contributing to climate change. Additionally, the production of aluminum is energy-intensive, often relying on fossil fuels, which further exacerbates environmental issues. The release of toxic chemicals and heavy metals during processing can contaminate soil and water, posing risks to both ecosystems and human health. Moreover, the waste generated, such as red mud, can cause severe environmental damage if not properly managed. Overall, the aluminum industry has a substantial environmental footprint that requires sustainable practices to mitigate its effects.</p>

- Q: Is it possible to utilize aluminum in the creation of innovative electronic devices?

- <p>Yes, aluminum can be used to make new types of electronic devices. Aluminum is a lightweight, corrosion-resistant, and highly conductive material, making it ideal for various electronic components. It's commonly used in heat sinks, casings, and wiring due to its thermal and electrical conductivity. Additionally, aluminum's malleability allows it to be shaped into intricate parts, which can be beneficial for compact and innovative designs in electronics. Furthermore, its abundance and low cost make it an attractive material for manufacturing new electronic devices.</p>

- Q: This question asks about the method to determine the strength of aluminum alloy, which is a measure of its ability to withstand stress or deformation before breaking.

- <p>The strength of aluminum alloy is calculated through a series of mechanical tests, primarily the tensile test. In this test, a sample of the alloy is subjected to a gradually increasing tensile force until it fractures. The yield strength is noted at the point where the alloy begins to deform plastically, and the ultimate tensile strength (UTS) is recorded at the point of fracture. The strength is expressed in units of stress (e.g., MPa or psi). Additionally, the hardness of the alloy can be measured using tests like the Brinell or Rockwell hardness test. These values, along with other properties like elongation and reduction of area, provide a comprehensive understanding of the alloy's strength and ductility.</p>

- Q: This question asks for examples of how recycled aluminum can be utilized.

- <p>Recycled aluminum has numerous applications, including the manufacturing of beverage cans, automotive parts, construction materials, and electronic components. It is also used in the production of aluminum foil, packaging materials, and various household items. Recycled aluminum is valued for its durability, lightweight properties, and energy efficiency in production, making it an environmentally friendly choice for many industries.</p>

- Q: This question asks about the impact of aluminum on the aging process in living organisms.

- <p>Aluminum's effect on the aging process is a subject of ongoing research and debate. Some studies suggest that aluminum can accumulate in the body over time, potentially contributing to age-related diseases such as Alzheimer's. It is hypothesized that aluminum may interfere with cellular function, disrupt enzyme activity, and cause oxidative stress, which are all factors associated with aging. However, the exact mechanisms and the extent of aluminum's role in aging are not fully understood. It's important to note that the human body naturally has mechanisms to excrete aluminum, and the contribution of aluminum to aging is not conclusively proven. More research is needed to establish a clear link between aluminum exposure and the aging process.</p>

- Q: Is aluminum a suitable material for constructing aerospace structures?

- <p>Yes, aluminum is widely used in aerospace structures due to its high strength-to-weight ratio, corrosion resistance, and ease of fabrication. It is particularly favored for aircraft frames, wings, and fuselage components. Aluminum alloys are also used in spacecraft and satellite structures for their lightweight properties and ability to withstand extreme temperatures.</p>

- Q: This question asks for the specific temperature at which aluminum oxide transitions from a solid to a liquid state.

- <p>The melting point of aluminum oxide (Al2O3) is approximately 2072掳C (3767.6掳F). It is a high melting point due to the strong ionic bonds between aluminum and oxygen atoms in the crystal structure. This high melting point makes aluminum oxide a common material in high-temperature applications such as refractory materials and abrasives.</p>

- Q: This question asks whether the energy consumption for producing recycled aluminum is lower compared to the production of new aluminum.

- <p>Yes, producing recycled aluminum requires significantly less energy than producing new aluminum. Recycling aluminum uses only about 5% of the energy needed to produce primary aluminum from bauxite ore. This is because recycling involves melting and recasting the metal, which is a much less energy-intensive process than mining, refining, and smelting new aluminum. As a result, recycling aluminum helps conserve energy and reduces greenhouse gas emissions associated with aluminum production.</p>

Send your message to us

Aluminum Prepainted Aluminum Coil for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords