Aluminum Pallet Aluminum Pipes

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Please see more info as belows:

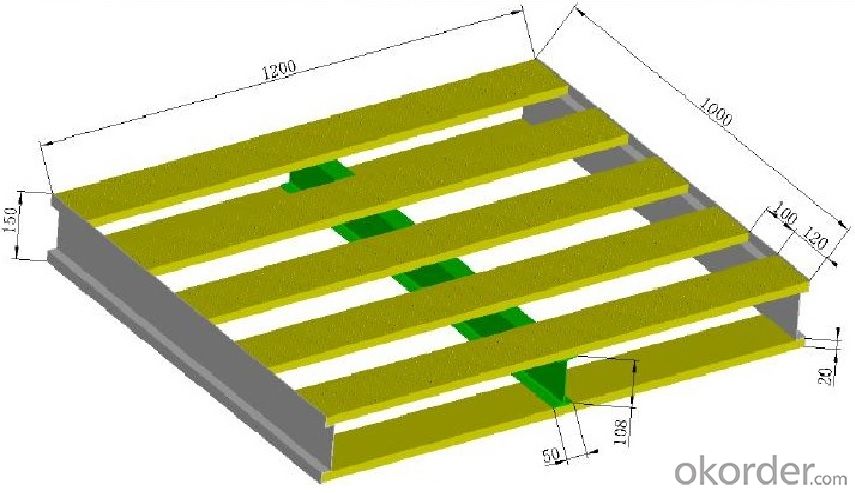

No. | Dimension(mm) | Weight(kg) | Alloy | Dynamic load | Static load | Load mode | Processing type |

1 | 1200×1000×153 | 14.84 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

2 | 1200×1000×150 | 14.38 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

3 | 1200×1000×150 | 21.56 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

4 | 1200×800×150 | 11.90 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

5 | 1200×800×150 | 17.62 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

6 | 1100×1100×150 | 14.39 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

7 | 1100×1100×150 | 20.96 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

8 | 1200×1000×150 | 14.13 | AL6061-T6 | 1.5t | 3t | Single side | Riveting |

9 | 1200×1000×150 | 18.60 | AL6061-T6 | 1.5t | 3t | Double side | Riveting |

- Q: What is the lifespan of aluminum pipes?

- The lifespan of aluminum pipes can vary depending on various factors such as the quality of the pipes, the environment in which they are installed, and how well they are maintained. However, under normal conditions, aluminum pipes can last for several decades.

- Q: What is the aluminum tube expanding device? What's the principle?

- Aluminum pipe is widely used in all walks of life, such as: automobiles, ships, aerospace, aviation, electrical appliances, agriculture, machinery and electrical, home, etc., the aluminum pipe in our life has been everywhere.

- Q: How can the aluminium tube cooler be welded?

- Car water tank comprises a vertical tube and the root, and tank truck riser for Q303 welding with WE53 special porous gun welding, the truck tank root and intercooler with WE53 welding wire with oxygen acetylene welding or cutting gun.

- Q: What is the maximum operating temperature for aluminum pipes?

- The maximum operating temperature for aluminum pipes can vary depending on the specific alloy used, but generally, it ranges from 300 to 400 degrees Fahrenheit (150 to 200 degrees Celsius).

- Q: Can aluminum pipes be used for cooling tower installations?

- Indeed, cooling tower installations can utilize aluminum pipes. Aluminum, a material known for its lightweight and resistance to corrosion, proves to be well-suited for cooling purposes. Its high thermal conductivity and durability render it commonly employed in the construction of heat exchangers and cooling systems. Moreover, aluminum pipes possess superior heat transfer properties, facilitating efficient heat dissipation and effective cooling. Nevertheless, it is crucial to carefully account for the cooling tower system's precise demands, encompassing factors such as temperature, pressure, and water chemistry. This diligence ensures compatibility and the ability of aluminum pipes to endure the operational conditions.

- Q: Do aluminum pipes require any special maintenance?

- In general, there is no need for any special maintenance for aluminum pipes. Nevertheless, it is crucial to ensure that they remain free from debris or substances that might lead to corrosion. To maintain the appearance and functionality of the aluminum pipes, it is adequate to clean them regularly using mild soap and water. Furthermore, it is recommended to check for and fix any leaks or damages to guarantee the longevity and efficiency of the piping system. Overall, aluminum pipes are renowned for their durability and rust resistance, making them a low-maintenance choice for diverse applications.

- Q: What is the cost of aluminum pipes compared to other materials?

- The cost of aluminum pipes can vary depending on various factors such as the size, thickness, and grade of the pipe, as well as the current market conditions. However, generally speaking, aluminum pipes tend to be more affordable compared to other materials such as stainless steel or copper. Aluminum is a lightweight material that is easily accessible and abundant, which helps to keep its production costs relatively lower. Additionally, aluminum pipes do not require as much energy or resources to manufacture compared to other metals, contributing to their lower cost. On the other hand, materials like stainless steel or copper are generally more expensive due to their higher production costs and limited availability. Stainless steel pipes, for example, require additional alloying elements and complex manufacturing processes, which increase their price. Copper pipes, known for their excellent heat conductivity, are also more expensive due to the higher cost of copper as a raw material. It is important to note that the specific cost comparison between aluminum pipes and other materials may vary depending on the market conditions and specific project requirements. Therefore, it is advisable to consult with suppliers or conduct thorough research to get accurate pricing information for the desired materials.

- Q: Requirements of storage and transportation in the process of import and export of 1. aluminium tube, aluminium wire and aluminium foilFor example, the temperature, humidity, packaging and other requirements, storage and transportation quality of goods.2 aluminum tube, aluminum wire, aluminum foil by import and export supervisionAre products subject to the supervision of the import and export quality supervision department, and whether or not the quality system certification is required, whether or not the quality certification marks are added?. StopWe have to do an experiment report, this thing is not easy to find ah, we help out!

- This product can replace all kinds of solvent baking sealing products, applicable to all kinds of metal products over long period of rust prevention, aluminum has a good sealing effect. And for the metal copper, alloy steel, stainless steel, steel and other metal materials have excellent adhesion and anti rust properties; for lamps, metal crafts, fine locks, car and motorcycle accessories, such as electroplating tank hardware antirust bright decoration etc.

- Q: What are the different types of aluminum pipes available?

- Various applications have access to a range of aluminum pipes, each with distinct characteristics. 1. Seamless Aluminum Pipes: These pipes lack welds or seams, making them highly durable and capable of withstanding high pressure and temperature. Industries such as aerospace, automotive, and marine commonly employ seamless aluminum pipes. 2. Welded Aluminum Pipes: By welding together two or more aluminum pieces, these pipes provide a cost-effective solution suitable for applications that do not require the same strength as seamless pipes. Construction, irrigation, and HVAC systems often utilize welded aluminum pipes. 3. Extruded Aluminum Pipes: Shaping heated aluminum billets through a die results in continuous pipes with a constant cross-section. These pipes are lightweight, corrosion-resistant, and possess excellent thermal conductivity, making them prevalent in construction, automotive, and electrical industries. 4. Drawn Aluminum Pipes: Reducing the diameter and increasing the length of an extruded aluminum tube through a die produces drawn aluminum pipes with improved surface finish and tighter tolerances. Furniture, lighting fixtures, and heat exchangers frequently incorporate drawn aluminum pipes. 5. Aluminum Alloy Pipes: Aluminum alloys, consisting of aluminum mixed with elements like copper, magnesium, or zinc, form these pipes. Aluminum alloys enhance strength, corrosion resistance, and other pipe properties. Aerospace, automotive, and structural engineering industries utilize aluminum alloy pipes. When selecting an aluminum pipe, it is crucial to consider project or application-specific requirements, such as pressure rating, temperature resistance, corrosion resistance, and cost. Careful consideration of these factors ensures the most suitable option is chosen.

- Q: I took a refrigerator leak, and found the leak behind my back. Found a very small mouth, I heard that aluminum welding, I do not know how you master how to solve this problem. With what method can make up?. Thank you。

- Cut off at the point of leakage, with a copper knot to connect the head, you should pay attention not to force too much.Now the refrigerator tube is the use of aluminum tube or Bondi tube (Bondi tube, that is galvanized steel pipe, in fact, iron pipe, iron pipe above the paint once lost, it is easy to rust. )The aluminum pipe is more corrosion resistant than the iron tube, and the iron pipe is not corrosion resistant. In fact, the best or copper pipe, but now no manufacturers have produced, mainly or cost.

Send your message to us

Aluminum Pallet Aluminum Pipes

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords