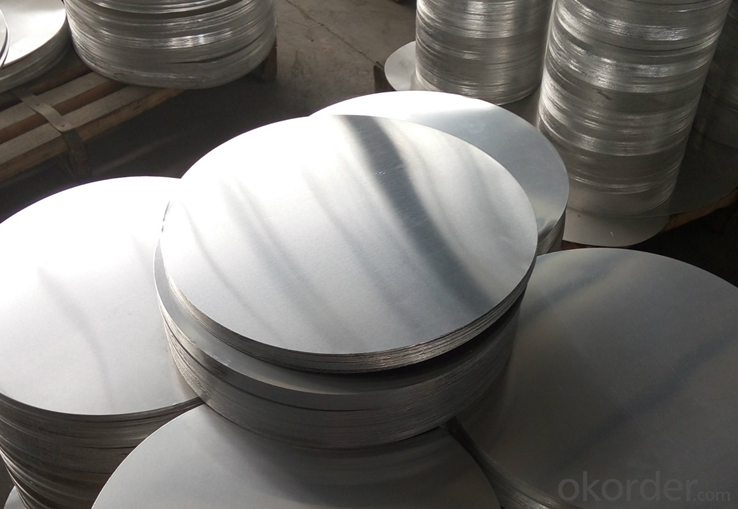

Aluminum Mill Finished Circle for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Mill finished Aluminum Circle for Cookware

Specifications

Alloy | AA1050,AA1060,AA1100 AA3003etc. |

Temper | O,H14 |

Thickness | 0.5MM-4MM |

Diagonal | 100-1200MM |

Standard | GB/T 3880-2006 |

The villa with Mediterranean style omits the heavy and complicated sculptures and decorations. It makes people feel that they would recover their original simplicity, and feel that the building is so distinctive, through the simple architectural lines and the perfectly round trimming. The design with the asymmetry features is full of romantic passion in the sunshine.

Housing and Building All the components of the Housing and Building are prefabricated in the manner of factory standardized production, and then assembled on-site, by which the construction mode of component prefabrication and on-site assembly can be realized. Characterized by no wet operation, short construction period, reduction of noise, dust and waste, small impact by climate conditions, easy disassembly and recycling, it is consistent with the requirements on energy conservation and environmental protection of green buildings.

Features:

• High manufacturing accuracy

• Smooth surface

• No waves

• High strength of extension and yield

• Well packaged

Application:

It is used in cookware, engineering, lighting purpose, fried pans, non-sticky pans, cooking pots, kettles, hard anodize cook wire, pressure cooker and house hold utensils, reflector of the light, etc

Benefit:

1. Thermal Insulation

The advanced exterior overall thermal insulation meets the updated state energy-saving standards for buildings. It refrains from the cold and thermal bridges phenomenon, and keeps buildings away from damages such as dampness, distortion, mildew and corrosion.

The unique heat reflection and ventilation layer design can make better insulation effects. Temperature can be reduced by five to eight degrees.

2. Seismic and Wind Resistance

Withstand the shock of 9 on the Richter scale.

The dense light gauge steel and column are connected in flexible method with screws and bolts, which can absorb the energy of earthquake. There are fittings between foundation and wall, which are resistant to pull out and shear. The total weight of the house is light, which is only 1/6 of traditional concrete houses. Therefore it has better anti-seismic performance.

Can endure typhoon of 12 levels

There are special fittings among roof, floor, wall and basement. The strong connection can help resist typhoon of 12 levels.

3. Roof Load-bearing and Fireproof

The roof can withstand 1500mm thickness snow.

The structure can be designed according to climate requirements.

Low-rise building fire resistance meet 2.5h (Grade Ⅱ) design standard.

High-rise building fire resistance meet 3h (Grade Ⅰ) design standard.

Wall and floor slab use special technology which can meet 3h refractory limit.

4. Sound Insulation

Improved technology on sound insulation and shock absorption meet the state building standards for sound insulation. Special methods are performed, especially towards the audio frequency ranging from 250 to 1000 Hz which is the most sensitive to ears, in order to create a quiet and comfortable living environment.

5. Moisture-proof and Ventilation

There is a gap between wall and roof truss, so the air can flow inside.

There is a one-way ventilation layer in the composite wall, which is able to make the wall ‘breathing’. This means moisture can be reduced inside of the door.

6. Durable

90 years structure safety guarantee

Special coating technology enables the structural materials to have the self-restoration function to prevent rust and corrosion.

Envelope materials using new lightweight building materials to achieve fire resistant,anti-corrosion and anti-moth.

7. Energy Efficient and Environmental Protection

FAQ:

1.How about the installation? For example, the time and cost?

To install 200sqm house needs only 45 days by 6 professional workers. The salary of enginner is USD150/day, and for workers, it's 100/day.

2.How long is the life span of the house?

Around 50 years

3. And what about the loading quantity?

One 40'container can load 140sqm of house.

Images:

- Q: Is it possible to utilize aluminum as a component in battery technology?

- <p>Yes, aluminum can be used in batteries. Aluminum-air batteries are a type of metal-air battery that uses aluminum as the anode. These batteries have a high energy density and are lightweight, making them suitable for certain applications. However, they also have challenges such as the need for a specific electrolyte and issues with aluminum corrosion, which limit their practical use compared to more common battery technologies like lithium-ion batteries.</p>

- Q: This question asks about the various applications of aluminum in the construction industry.

- <p>Aluminum is widely used in construction due to its lightweight, high strength, and corrosion resistance. It is commonly used in window frames, door frames, curtain walls, and roofing systems for its durability and energy efficiency. Aluminum is also utilized in structural components such as beams and columns, as well as in the manufacturing of prefabricated buildings. Additionally, it is used in the electrical wiring and conduits within buildings due to its excellent conductivity. Its versatility makes it a popular choice for both residential and commercial construction projects.</p>

- Q: What precautions should be taken when handling or working with aluminum?

- <p>When working with aluminum, several safety measures should be taken: Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to prevent inhalation of aluminum dust. Ensure proper ventilation to avoid the buildup of dust or fumes. Use tools and equipment designed for aluminum to prevent sparks or heat buildup, which can cause fires. Store aluminum in a dry place to prevent corrosion. Always follow the manufacturer's guidelines for handling and processing aluminum, and be aware of the specific hazards associated with the aluminum products you are working with.</p>

- Q: This question asks for a brief explanation of the process of recycling aluminum.

- <p>Aluminum recycling involves several steps. First, aluminum waste is collected and sorted. It is then cleaned to remove any contaminants. The cleaned aluminum is melted in a furnace at high temperatures, which is an energy-efficient process as aluminum has a lower melting point compared to other metals. The molten aluminum is then poured into molds to form new products. This process is highly sustainable as it saves energy and reduces waste, with recycled aluminum requiring only 5% of the energy needed to produce new aluminum from raw materials. Recycled aluminum maintains its quality, making it an ideal material for continuous recycling.</p>

- Q: What is the primary application of aluminum in various industries and everyday life?

- <p>Aluminum is most commonly used in the manufacturing of cans and packaging materials due to its lightweight, corrosion resistance, and recyclability. It is also extensively used in construction for window frames, roofing, and facades. In transportation, aluminum is a key material in the production of vehicles, particularly in the aerospace industry for aircraft and automotive industry for car bodies, due to its strength-to-weight ratio. Additionally, it is used in electrical components and electronics due to its good conductivity and malleability.</p>

- Q: Is it possible to utilize aluminum in the manufacturing of tools and equipment?

- <p>Yes, aluminum can be used to make tools and equipment. It is valued for its lightweight, corrosion resistance, and high strength-to-weight ratio. Aluminum is commonly used in various applications such as aircraft manufacturing, automotive parts, and consumer electronics. It is also used in the construction of certain types of tools, particularly those that require lightness and durability without the need for extreme strength. However, for applications requiring high strength or resistance to high temperatures, other materials might be more suitable.</p>

- Q: What are the typical applications for aluminum sheet metal?

- <p>Aluminum sheets are versatile and have numerous applications due to their lightweight, corrosion resistance, and strength. Some common uses include construction for roofing and siding, automotive parts such as body panels and heat sinks, packaging for food and beverages, aerospace for aircraft components, and in the manufacturing of electronic devices due to its good thermal conductivity. They are also used in signage, furniture, and various decorative applications.</p>

- Q: This question asks for a brief overview of the characteristics or qualities of aluminum nitride, a chemical compound.

- <p>Aluminum nitride (AlN) is a covalent, ceramic material known for its exceptional properties. It has a high thermal conductivity, which is about two-thirds that of copper, making it useful in electronics for heat dissipation. It's also an electrical insulator, exhibiting high electrical resistivity. Aluminum nitride is characterized by its high thermal stability, resistance to thermal shock, and excellent mechanical strength. It's chemically inert, resistant to most acids and alkalis, and has a high melting point of approximately 2200掳C. These properties make it suitable for applications in high-temperature electronics, as a substrate for semiconductor devices, and in the automotive industry for heat sinks and other heat management components.</p>

- Q: Is it possible to utilize recycled plastic or paper for manufacturing new products instead of sourcing new materials?

- <p>Yes, recycled plastic and paper can be used to create new products, reducing the need for new materials. This process not only conserves natural resources but also decreases waste in landfills. Recycled paper can be used to make new paper products, packaging, and even some types of construction materials. Similarly, recycled plastics can be repurposed into various products such as clothing, furniture, and new plastic items. However, it's important to note that the quality of recycled materials may vary, and not all plastics or paper products can be recycled effectively. The recycling process also requires energy, so it's crucial to balance the environmental benefits with the energy costs and potential for contamination during recycling.</p>

- Q: This question asks for common uses of aluminum in everyday life.

- <p>Aluminum is widely used in daily life due to its lightweight, corrosion resistance, and affordability. Some applications include: 1) Food and beverage cans for preserving food and drinks. 2) Aluminum foil used for cooking and food storage. 3) Construction materials, such as window frames and roofing. 4) In transportation, like car parts and airplane components to reduce weight. 5) Electrical wiring due to its high conductivity. 6) Household items like pots and pans, and furniture. 7) Packaging materials for various products. 8) In sports equipment like bicycle frames and tennis rackets. These applications highlight aluminum's versatility and importance in everyday life.</p>

Send your message to us

Aluminum Mill Finished Circle for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords