Aluminum Hot Rolled Circle for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of HOT Rolled Aluminum Circle for Cookware Description

• Product: Aluminim Circle

• Application: It is used in cookware, engineering, lighting purpose, fried pans, non-sticky pans, cooking pots, kettles, hard anodize cook wire, pressure cooker and house hold utensils, reflector of the light, etc

• Advantage: Deep drawing and hard anodizing quality Aluminum Circle Sheet can be supplied. Our Aluminum Circle is RoHS and REACH compliance and uses well-protected packing. Our circles are excellent material for producing cookware, utensil, pots, pans and kettles.

2.Main Features of the HOT Rolled Aluminum Circle for Cookware

• High manufacturing accuracy

• Smooth surface

• No waves

• High strength of extension and yield

• Well packaged

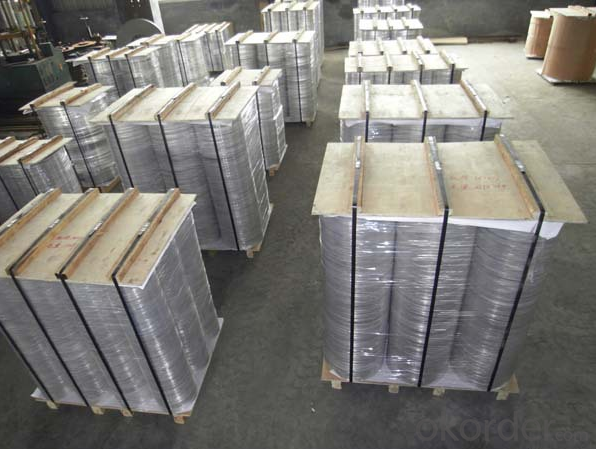

3. HOT Rolled Aluminum Circle for Cookware Images

4.HOT Rolled Aluminum Circle for Cookware Specification

Alloy | AA1050,AA1060,AA1100 AA3003etc. |

Temper | O,H14 |

Thickness | 0.5MM-4MM |

Diagonal | 100-1200MM |

Standard | GB/T 3880-2006 |

5.FAQ of HOT Rolled Aluminum Circle for Cookware

We have organized several common questions for our clients,may help you sincerely:

(1).How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

(2).Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

(3).What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: This question asks about the interaction between aluminum and electromagnetic radiation, specifically how aluminum influences or is affected by such radiation.

- <p>Aluminum has a high electrical conductivity and is a good reflector of electromagnetic radiation. It reflects a wide range of frequencies, including visible light, ultraviolet, and infrared radiation. Due to its reflective properties, aluminum is used in applications such as reflective coatings for insulation and mirrors. It also has the ability to shield against electromagnetic radiation, making it a common material in the construction of Faraday cages, which are used to block external electromagnetic fields. Aluminum's effect on electromagnetic radiation is primarily through reflection and shielding, rather than absorption or transmission.</p>

- Q: Is it feasible to use pure aluminum for the production of coins or medals that maintain their longevity and aesthetics?

- <p>While pure aluminum is lightweight and corrosion-resistant, it is not typically used for making coins or medals due to its low melting point and softness. Coins and medals often require materials that are harder and more durable to withstand wear and tear over time. Additionally, pure aluminum is less visually appealing as it does not have the luster or reflective qualities of other metals like silver or gold. Alloys are generally preferred for coinage and medals because they offer better durability, resistance to wear, and can be tailored to have specific properties like hardness and resistance to corrosion.</p>

- Q: Is aluminum a suitable material for use in nuclear power plants?

- <p>Yes, aluminum can be used in nuclear power plants, but its application is limited due to its reactivity with neutrons. Aluminum is used in non-nuclear grade components such as cooling systems, electrical equipment, and structural supports. However, it is not used in the core or in high-radiation areas due to its tendency to absorb neutrons, which can lead to transmutation and the production of radioactive isotopes. Materials like stainless steel, zirconium alloys, and other neutron-resistant materials are preferred for core components and high-radiation environments.</p>

- Q: This question asks for a list of negative aspects or drawbacks associated with the use of aluminum.

- <p>Aluminum, while widely used, has several disadvantages. It is non-magnetic and non-conductive, which limits its use in certain applications requiring these properties. Aluminum is also relatively soft and can dent or scratch easily, affecting its durability in some contexts. Additionally, its production process is energy-intensive and contributes to environmental pollution. Furthermore, aluminum can have negative health impacts if ingested in large quantities, potentially leading to neurological disorders. Lastly, aluminum's light weight can be a disadvantage in applications where greater strength or weight is required.</p>

- Q: What is the reaction of aluminum with alkaline solutions and what products are formed?

- <p>Aluminum reacts with alkaline solutions in a process known as an acid-base reaction. When aluminum comes into contact with an alkaline solution, such as sodium hydroxide (NaOH), it forms sodium aluminate (NaAlO2) and hydrogen gas (H2). The reaction can be represented by the following chemical equation: 2Al + 2NaOH + 6H2O 鈫?2NaAl(OH)4 + 3H2. In this reaction, aluminum acts as an acid, donating protons to the hydroxide ions (OH-) from the alkaline solution, resulting in the formation of a salt and hydrogen gas.</p>

- Q: Is it possible to use aluminum as a treatment for diseases?

- <p>Aluminum is not typically used to treat diseases directly. It is a common element found in the Earth's crust and is used in various industries, such as manufacturing and construction. However, aluminum compounds can have medicinal uses in specific contexts. For example, aluminum hydroxide is used as an antacid to neutralize stomach acid and treat conditions like heartburn. It's important to note that aluminum should not be ingested in large amounts, as it can be harmful. Always consult a healthcare professional for proper treatment and medication advice.</p>

- Q: Explain how the inclusion of copper impacts the characteristics of aluminum alloys.

- <p>The addition of copper to aluminum alloys significantly enhances their strength and hardness. Copper is one of the most effective alloying elements for aluminum, leading to the formation of a series of age-hardenable alloys known as the 2xxx series. These alloys, such as 2024, are characterized by their high strength-to-weight ratio and are often used in aerospace applications, structural components, and transportation equipment. The copper atoms in the aluminum matrix form precipitates that strengthen the alloy through a process called precipitation hardening. However, the addition of copper also reduces the alloy's ductility and corrosion resistance, necessitating careful control of the copper content and heat treatment processes to optimize the alloy's properties for specific applications.</p>

- Q: This question asks for a list of typical aluminum alloys that are commonly used in various industries and applications.

- <p>Aluminum is widely used in various forms of alloys due to its lightweight and corrosion resistance. Some common aluminum alloys include: 1) 1000 series, which is pure aluminum with 99.00% minimum aluminum content; 2) 2000 series, known for their strength and are used in aircraft structures; 3) 3000 series, which are non-heat treatable and have good formability, used in cooking utensils and chemical equipment; 4) 5000 series, noted for their resistance to saltwater corrosion, used in marine applications; 5) 6000 series, which are heat treatable and offer good mechanical properties, used in construction and automotive parts; 6) 7000 series, the strongest aluminum alloys, used in aircraft and high-strength structural applications. These alloys are chosen for their specific properties to meet the demands of different industries.</p>

- Q: Describe the process of manufacturing aluminum from its raw materials to the final product.

- <p>The manufacturing process of aluminum involves several key steps. Initially, bauxite ore, the primary source of aluminum, is mined. The ore is then crushed and washed to remove impurities. Next, the bauxite is processed through the Bayer process, which involves digestion in a caustic soda solution to produce a solution of sodium aluminate. This solution is then seeded with aluminum hydroxide, causing crystals to form, which are then filtered out, washed, and calcined to produce aluminum oxide, also known as alumina. Finally, in the Hall-H茅roult process, alumina is dissolved in a cryolite bath and electrolyzed to extract pure aluminum. This process involves passing an electric current through the bath, causing aluminum ions to be reduced and collected at the cathode as molten aluminum, which is then tapped off and cast into various forms for use in manufacturing.</p>

- Q: This question asks about the steps involved in preparing aluminum foil for use in food packaging.

- <p>Aluminum foil for food packaging is processed through several steps. First, aluminum ingots are melted and then rolled into thin sheets. The sheets are cleaned to remove any impurities and coated with a thin layer of food-grade protective coating to prevent any chemical reactions with the food. Next, the sheets are cut into rolls or sheets of standard sizes. The aluminum foil is then inspected for quality, ensuring it is free from defects and safe for food contact. Finally, it is packaged and shipped to manufacturers who use it to wrap or package food products.</p>

Send your message to us

Aluminum Hot Rolled Circle for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords