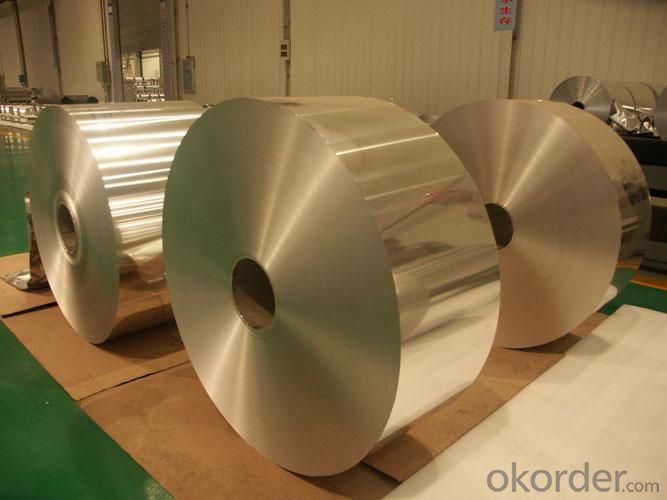

Aluminum Foilstock for Household Packaging

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20Tons m.t.

- Supply Capability:

- 6000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick details of Aluminum Foilstock

|

Alloy: |

1235/8011/8079 |

|

Temper: |

H14/H16/H24/H26 |

|

Thickness: |

0.28~0.3mm (±0.01mm) |

|

Width: |

1000-2020mm (±1mm) |

|

Core I.D: |

405/505/508mm |

|

Surface Quality: |

Good appearance with no-crack and well-distribute grain. |

|

Build Up: |

Tight slit edges free from cracks, layer to layer shift not more than 2 mm. |

|

Profile: |

-0/+1% |

|

Flatness: |

Mill flatness coil having slight edge waviness rather than center buckles shall be acceptable. |

|

Rolling Performance: |

Re-rollable to the final desired gauges |

|

Standard: |

GB/T3198 / ASTM-B209 |

Usage/Application of Aluminum Foilstock

Household foils, container foils, lidding foils, industrial foils, lamination foils.

Packaging & Delivery of Aluminum Foilstock

Packing: seaworthy wooden box with pallet

Delivery: to be loaded by 1 x 20 feet container

- Q: This question asks for recent applications of aluminum in the construction industry.

- <p>Aluminum has found new uses in construction due to its lightweight, durability, and sustainability. It's used in curtain walls, window frames, and doors for its strength and resistance to corrosion. Aluminum is also utilized in modular construction, where prefabricated components can be quickly assembled on-site. Its high thermal conductivity makes it suitable for energy-efficient building envelopes. Additionally, aluminum's recyclability and low environmental impact make it a popular choice for green buildings. New technologies have also enabled the use of aluminum in 3D-printed structures, offering innovative design possibilities.</p>

- Q: Is it possible to use aluminum as a substance that accelerates chemical reactions?

- <p>Aluminum is not typically used as a catalyst in chemical reactions. Catalysts are substances that increase the rate of a chemical reaction without being consumed in the process. Aluminum, being a metal with a +3 oxidation state, does not readily participate in reactions where it could act as a catalyst. Instead, it is more commonly used in its elemental form for structural purposes or as a reducing agent in certain chemical processes. However, aluminum compounds, such as alumina (Al2O3), can be used as catalysts or catalyst supports in specific industrial applications.</p>

- Q: Is it possible to recycle old aluminum products and what are the benefits of doing so?

- <p>Yes, old aluminum products can be recycled. Recycling aluminum is highly beneficial as it conserves resources, saves energy, and reduces waste. The process of recycling aluminum requires only 5% of the energy needed to produce new aluminum from raw materials, making it an environmentally friendly option. Additionally, recycling helps to decrease the amount of aluminum that ends up in landfills, thus reducing the environmental impact of mining and processing new aluminum.</p>

- Q: Is it possible to utilize recycled aluminum for the production of cars or other types of vehicles?

- <p>Yes, recycled aluminum can be used to make cars and other vehicles. It is common practice in the automotive industry to use recycled aluminum in the manufacturing process due to its lightweight and strong properties. Recycled aluminum requires less energy to produce than new aluminum, making it more sustainable. It is used in various parts of vehicles, including engine components, body panels, and wheels. The use of recycled aluminum not only reduces waste but also contributes to energy savings and carbon emission reductions in vehicle production.</p>

- Q: This question asks for methods to enhance the ability of aluminum to resist corrosion.

- <p>To improve the corrosion resistance of aluminum, several methods can be employed: 1) Anodizing: This process creates a protective oxide layer on the aluminum surface, enhancing its resistance to corrosion. 2) Coating: Applying protective coatings such as paints or polymers can prevent direct contact with corrosive substances. 3) Alloying: Adding elements like magnesium or copper to aluminum can create alloys with better corrosion resistance. 4) Cathodic Protection: Using sacrificial anodes can protect aluminum from corrosion by diverting corrosion to the anode. 5) Proper Design: Designing structures to minimize water and dirt accumulation can reduce corrosion. 6) Regular Maintenance: Cleaning and inspecting aluminum components can help identify and address corrosion issues early.</p>

- Q: Can the recycling of aluminum be done in a closed loop system without any degradation in the material's quality?

- <p>Yes, aluminum can be recycled using a closed loop process without losing quality. Aluminum is infinitely recyclable, meaning it can be recycled over and over again without losing its properties. The recycling process involves melting the aluminum, which is much less energy-intensive than the original production from raw materials. This closed-loop recycling system helps maintain the quality of aluminum, making it an environmentally friendly and sustainable material.</p>

- Q: This question asks for an overview of the environmental effects resulting from the production of aluminum.

- <p>Aluminum production has several significant environmental impacts. The process is energy-intensive, contributing to high greenhouse gas emissions, primarily CO2, which exacerbates climate change. It also generates hazardous waste, such as red mud, a byproduct rich in alkaline and heavy metals that can contaminate soil and water if not properly managed. Air pollution is another concern, with emissions of particulates and sulfur dioxide affecting air quality. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction, impacting biodiversity. Water usage in the production process is substantial, which can strain local water resources. Lastly, the release of fluoride compounds can have detrimental effects on human health and the environment.</p>

- Q: This question asks for innovative applications of recycled aluminum in various industries or everyday life.

- <p>Recycled aluminum is finding new uses in various sectors due to its sustainability and strength. It's being used in the automotive industry to make lighter vehicles, reducing fuel consumption and emissions. In construction, it's used for building materials like window frames and roofing, known for durability and energy efficiency. Recycled aluminum is also employed in the aerospace industry for aircraft parts due to its lightweight and high strength-to-weight ratio. Additionally, it's used in packaging, reducing waste and conserving resources. In electronics, recycled aluminum is used in the manufacturing of various components, contributing to the circular economy.</p>

- Q: Is aluminum a suitable material for constructing aerospace structures?

- <p>Yes, aluminum is widely used in aerospace structures due to its high strength-to-weight ratio, corrosion resistance, and ease of fabrication. It is particularly favored for aircraft frames, wings, and fuselage components. Aluminum alloys are also used in spacecraft and satellite structures for their lightweight properties and ability to withstand extreme temperatures.</p>

- Q: This question asks for examples of alloys that include aluminum as one of their components.

- <p>Aluminum is a versatile metal that forms many alloys, enhancing properties like strength, corrosion resistance, and electrical conductivity. Some common aluminum alloys include: 1. 6061, used in aircraft structures and automotive parts due to its good mechanical properties and machinability. 2. 2024, known as 'Alclad', is strong and used in aircraft structures. 3. 7075, one of the strongest aluminum alloys, used in aerospace and military applications. 4. 3003, used for cooking utensils and chemical equipment due to its good corrosion resistance. 5. 5052, used in marine applications and food processing equipment for its excellent corrosion resistance. These alloys are widely used in various industries due to their unique properties.</p>

Send your message to us

Aluminum Foilstock for Household Packaging

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20Tons m.t.

- Supply Capability:

- 6000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords