Aluminum Foil Tape Synthetic Rubber Based Super Strong Adhesion and Holding Power - Packaging Tape Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

Synthetic Rubber Based Aluminum Foil Tape is of aluminum foil as the carrier, coating with solvent based acrylic, synthetic rubber-resin, or water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Synthetic Rubber Based Aluminum Foil Tape: widely used for seaming and jointing bonding of various vapor barriers, fixing thermal fin in refrigerators. Provide fast and permanent bond performance for vapor barrier against the moisture.

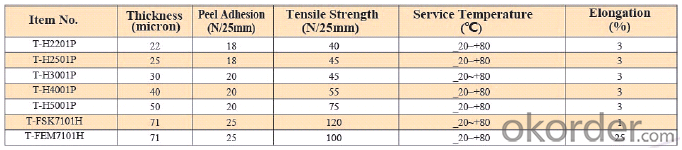

Typical Physical Reports of Synthetic Rubber Based Aluminum Foil Tape:

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Width1200mm; length according to customers’ requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Aluminum Foil Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Are there different colors of packaging tape?

- In the market, one can find various colors of packaging tape. Although clear is the most commonly used color, there are also options like brown, white, black, and even vibrant choices such as red, blue, green, and yellow. The multiple colors of packaging tape serve different purposes. For instance, brown tape is frequently employed for sealing boxes and packages, white tape is commonly used for labeling or writing on, and colored tapes can be utilized for color-coding or enhancing the appearance of packages. The presence of diverse colors enables individuals and businesses to select the tape that best suits their specific requirements.

- Q: Does packaging tape come in different finishes or textures for aesthetic purposes?

- Yes, packaging tape does come in different finishes or textures for aesthetic purposes. Some examples include glossy, matte, clear, colored, patterned, and even customizable options. These variations allow individuals and businesses to choose packaging tape that aligns with their branding or personal preferences.

- Q: Does packaging tape leave residue?

- Yes, packaging tape can leave residue on surfaces after it is removed.

- Q: Can packaging tape be used for sealing packages with sharp or pointed objects?

- Yes, packaging tape can be used for sealing packages with sharp or pointed objects. Packaging tape is designed to provide a secure seal for packages, and it can effectively hold together packages containing sharp or pointed objects. However, it is important to ensure that the tape is tightly secured and covers all edges and corners of the package to prevent any potential damage or injury during handling or transportation. Additionally, it is recommended to use extra layers of tape or additional protective measures, such as cushioning materials, to further secure and protect the sharp or pointed objects inside the package.

- Q: Is packaging tape safe to use on ceramic tiles?

- Yes, packaging tape is generally safe to use on ceramic tiles. Packaging tape is designed to adhere to a variety of surfaces, including ceramic tiles. However, it is important to ensure that the tape is removed carefully to avoid damaging the tile or leaving any residue behind. It is recommended to test a small inconspicuous area first to ensure that the tape does not cause any damage or discoloration. Additionally, it is always a good idea to follow the manufacturer's instructions and guidelines for using packaging tape on specific surfaces.

- Q: Does packaging tape come in different thicknesses?

- Indeed, various thicknesses can be found when it comes to packaging tape. One can find packaging tape in a range of thicknesses, which caters to diverse needs and demands. Heavier-duty tasks that necessitate extra durability and resilience usually call for thicker tapes. Conversely, thinner tapes are commonly utilized for lighter parcels or regular daily applications. The decision regarding the thickness depends on factors such as the weight and dimensions of the package in question, as well as the desired level of fortification.

- Q: How does packaging tape perform on porous surfaces?

- When it comes to porous surfaces, packaging tape shows decent performance, even though its adhesive strength might be slightly compromised compared to non-porous surfaces. This tape is specifically designed to stick to a variety of surfaces such as cardboard, paper, and fabric, all of which are commonly known as porous materials. However, because these surfaces are porous, some of the adhesive may seep into the material, resulting in a reduction in bond strength. Moreover, the tape may not stick as firmly to porous surfaces, which makes it more likely to peel or lift. To ensure maximum adhesion, it is recommended to make sure the surface is clean and dry before applying the tape.

- Q: What are the tapes for packing tape?

- There are many kinds: packing tape series: transparent adhesive tape, color adhesive tape

- Q: How do I cut packaging tape without scissors?

- If you don't have scissors, there are several alternative methods you can use to cut packaging tape. One option is to use a sharp knife or a utility knife, making sure to exercise caution and keep your fingers away from the blade. Another method is to use a box cutter or a pocket knife, again being careful to handle it safely. If you don't have any cutting tools available, you can try tearing the tape by firmly gripping it with both hands and pulling it apart swiftly. However, this method may not always result in a clean cut. Additionally, you can try using your teeth to tear the tape, but this is not recommended as it could potentially damage your teeth or cause injury. Remember to always prioritize safety and exercise caution when using any sharp objects to cut packaging tape.

- Q: Is packaging tape resistant to punctures or tears?

- Packaging tape, in general, exhibits resistance to punctures or tears. Its purpose is to possess strength and durability, specifically for the task of securing and sealing packages. Packaging tape derives its composition from materials like polypropylene or polyester, which possess high tensile strength and provide exceptional resistance against punctures or tears. Moreover, packaging tape commonly possesses adhesive properties that further augment its capacity to withstand punctures or tears. Nevertheless, it is crucial to acknowledge that the extent of resistance may fluctuate based on the particular type and quality of packaging tape employed.

Send your message to us

Aluminum Foil Tape Synthetic Rubber Based Super Strong Adhesion and Holding Power - Packaging Tape Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords