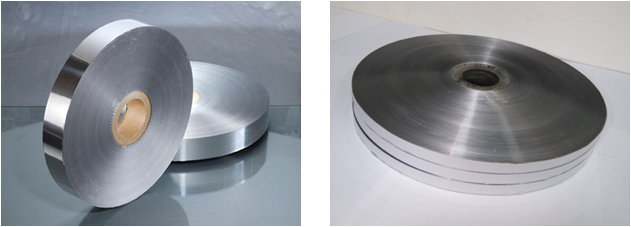

Aluminum Foil Facing Mylar Foil Shielding Foil for Coaxial Cable Communication Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mylar foil Shielding Foil for Coaxial Cable

Shielding Mylar foil

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

Application: the product is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

AL-PET laminated foil

nDescription: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

nDescription: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

nConstruction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

nDescription: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

nConstruction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

Copper polyester foil

nDescription: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

- Q: What are some effective ways to utilize aluminum foil in the kitchen?

- <p>Using aluminum foil effectively in the kitchen can enhance cooking and food preparation. Here are a few tips: 1) Line baking sheets to prevent food from sticking and make cleanup easier. 2) Create a tent over food when roasting to retain moisture and prevent over-browning. 3) Use foil to wrap individual portions for steaming or baking, which can be helpful for portion control. 4) Create a foil packet for cooking fish or vegetables on the grill or in the oven, which helps to steam and retain flavors. 5) Use foil to shape and mold food, such as a bowl for a souffl茅 or a mold for jello. 6) Double or triple layer the foil for durability when wrapping meats or creating containers. 7) Cut a small piece of foil to cover a small dish or to create a makeshift lid. Always handle with care when removing hot foil from the oven, as it can be very hot.</p>

- Q: Is it possible for metal shavings to contaminate food when using aluminum foil with a shiny side?

- <p>There is minimal risk of metal shavings getting into food when using aluminum foil facing. Aluminum foil is designed to be safe for food contact and is generally resistant to shedding particles. However, if the foil is damaged or handled roughly, small particles could potentially come off. To mitigate this risk, ensure the foil is in good condition, avoid tearing it, and handle it carefully to prevent any metal contamination.</p>

- Q: Explain the distinctions between aluminum foil facing and tin foil, including their composition and uses.

- <p>Aluminum foil facing and tin foil are both thin sheets of metal used for various purposes, but they differ in composition and properties. Aluminum foil facing is a thin layer of aluminum bonded to a substrate, often used in construction for insulation, while tin foil is pure tin and is used for wrapping food or as a decorative element. Aluminum foil is lightweight, corrosion-resistant, and conducts heat well, making it ideal for cooking and insulation. Tin foil, on the other hand, is less common in everyday use due to its higher cost and lower durability compared to aluminum. It is often used in niche applications such as art and craft projects or for certain types of food packaging that require a barrier to light and oxygen.</p>

- Q: What are some lesser-known applications of aluminum foil in the kitchen?

- <p>Aluminum foil facing has several creative uses in the kitchen beyond just wrapping food. It can be used to cover baking dishes to prevent spills and messes in the oven, line baking sheets for easy cleanup, or create a makeshift roasting bag for cooking meats. It can also be used to sharpen knives by folding it into a book shape and running the blade through the sharp edges, or to create a non-stick surface for cooking by lining molds or baking pans. Additionally, it can be used to scrub pots and pans, removing stuck-on food, or to create a barrier between food and direct heat to prevent burning. These uses showcase the versatility of aluminum foil in the kitchen.</p>

- Q: Explain the differences between food wrap and aluminum foil facing in a few sentences.

- <p>Food wrap, also known as plastic wrap, is a thin, flexible plastic film used to cover and preserve food, keeping it fresh and protected from contaminants. It's typically clingy and transparent, allowing you to see the food inside. Aluminum foil facing, on the other hand, is a type of laminate that has a layer of aluminum foil bonded to a plastic film. This facing is used for various purposes, including increasing the barrier properties of the plastic, providing a shiny appearance, and enhancing the product's durability. It's often used in packaging to protect and preserve food items, but it's not as clingy or transparent as food wrap and is not meant for direct contact with food in the same way.</p>

- Q: Can aluminum foil be used as a material for crafting a pot holder or pot lid holder?

- <p>While aluminum foil is heat resistant to a certain extent, it is not recommended for making a pot holder or pot lid holder due to its low melting point and potential to conduct heat, which could lead to burns or damage to the foil. Instead, consider materials designed for heat resistance such as silicone, fabric with heat-resistant properties, or insulated materials specifically made for kitchen use. These materials are safer and more effective for handling hot pots and lids.</p>

- Q: Describe the most effective methods for utilizing aluminum foil in baking processes.

- <p>The best way to use aluminum foil in baking involves lining the baking sheet to prevent food from sticking and to simplify cleanup. Preheat the foil by placing it on the sheet and heating the oven before putting in the food. For even cooking, ensure the foil doesn't touch the heating elements. Use foil to wrap foods like potatoes or fish for steaming, or create packets for en papillote cooking. When using foil to cover food, tent it loosely to allow for air circulation. For browning, remove the foil during the last part of baking. Always handle with care to avoid tearing and ensure椋熷搧瀹夊叏.</p>

- Q: What are the most suitable materials for covering food to ensure safety and freshness?

- <p>The best materials for food covers include food-grade silicone, beeswax wraps, and BPA-free plastic. Food-grade silicone is durable, heat-resistant, and can be reused. Beeswax wraps are eco-friendly, reusable, and can be used in the fridge or freezer. BPA-free plastic wraps are commonly used and are good for single use, but ensure they are microwave-safe if you plan to reheat food. Always check for food safety certifications and avoid materials that can leach harmful chemicals into your food.</p>

- Q: Is it possible to recycle aluminum foil with a facing layer? If yes, what is the process involved?

- <p>Yes, aluminum foil facing can be recycled. The process typically involves separating the aluminum from the facing material. This is done by specialized recycling facilities that use methods such as shredding, washing, and magnetic separation to remove impurities. The aluminum is then melted down and repurposed into new products. It's important to check local recycling guidelines, as some facilities may not accept foil with a facing layer due to the difficulty in separation or the presence of non-recyclable components.</p>

- Q: Is it possible to use aluminum foil facing as a wrap for lunch boxes?

- <p>Yes, you can use aluminum foil facing to make a wrap for lunch boxes. Aluminum foil is a versatile material that is commonly used for food packaging due to its ability to keep food fresh and protected. It's lightweight, easy to use, and can be wrapped around food items to keep them insulated and prevent spills. However, it's important to ensure that the foil is food-grade and clean before use to maintain food safety.</p>

Send your message to us

Aluminum Foil Facing Mylar Foil Shielding Foil for Coaxial Cable Communication Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords