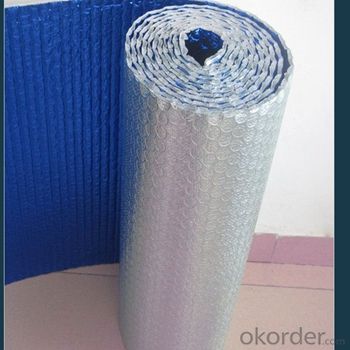

Aluminum Foil Facing LDPE Film Bubble Foil Roofing Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t

- Supply Capability:

- 566755 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum foil facing insulation for Roofing Insulation

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

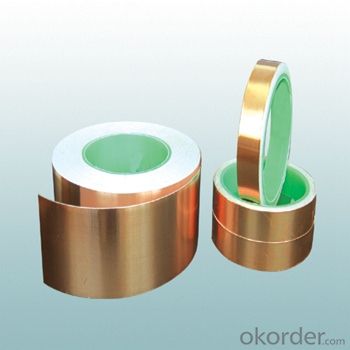

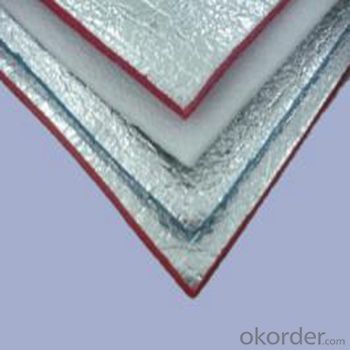

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Burst strength | N | 43 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

What is the storage condition?

1,The products should be stored at room temperature and kept from wet and heat source.

2, It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

3, The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: This question asks for a method to determine the thickness of an aluminum foil sheet.

- <p>To measure the thickness of an aluminum foil sheet, you can use a digital caliper or a micrometer. Place the foil between the jaws of the caliper and take the measurement. If you don't have these tools, you can use the 'multiple fold' method: fold the foil in half repeatedly and measure the total thickness after several folds, then divide by the number of layers to estimate the single layer thickness. For a more precise measurement, especially for thinner foils, consider using a thickness gauge designed for measuring thin materials.</p>

- Q: Can aluminum foil facing be used to create a thicker pizza crust compared to standard crusts?

- <p>Yes, you can use aluminum foil facing to make a thicker pizza crust. The foil provides a solid surface to prevent the dough from spreading too thin. To achieve a thicker crust, roll out your dough to your desired thickness and place it on the foil. Make sure the edges are thicker than the center for a traditional pizza crust look. Pre-bake the crust if necessary to set its shape before adding toppings.</p>

- Q: What are the eco-friendly options available to replace plastic containers?

- <p>Yes, there are several alternatives to plastic containers that are more environmentally friendly. Glass containers are a popular choice due to their durability and ability to be reused multiple times. Stainless steel containers are also a great option as they are long-lasting and do not leach chemicals. Biodegradable materials like bamboo, silicone, and certain types of plant-based plastics are other alternatives. Additionally, using cloth bags or reusable food wraps can help reduce the need for single-use plastic containers.</p>

- Q: Is it possible to use aluminum foil as a cooking utensil for stir-frying or sauteing food?

- <p>While aluminum foil can be used in some cooking applications, it is not recommended for stir-frying or sauteing due to its low melting point and potential for tearing. Aluminum foil can melt at high temperatures, which are often used in stir-frying and sauteing, leading to a fire hazard or uneven cooking. Additionally, the foil may tear or puncture easily, releasing aluminum particles into the food, which is not safe. Instead, use proper cookware like non-stick pans or stainless steel for these cooking methods.</p>

- Q: Is it safe to use aluminum foil with a nonstick coating for cooking or baking purposes?

- <p>Using nonstick-coated aluminum foil for cooking or baking is generally safe, but it's important to follow the manufacturer's guidelines regarding temperature limits. Nonstick coatings are designed to withstand high temperatures, but excessive heat can cause them to break down or release harmful fumes. Always ensure the foil is placed in a way that the nonstick side does not come into direct contact with the heat source to prevent damage to the coating. Additionally, avoid using sharp or abrasive objects on the nonstick surface to maintain its integrity.</p>

- Q: This question asks for a method to clean oil stains that have occurred on aluminum foil used to cover food in a microwave.

- <p>To clean oil stains from aluminum foil used in the microwave, first let the foil cool down to avoid burns. Then, gently wipe the surface with a paper towel to remove excess oil. For stubborn stains, mix a solution of warm water and dish soap. Dip a soft cloth or sponge into the solution and gently scrub the foil. Rinse with warm water and dry thoroughly. For severe stains, you can also use a mixture of baking soda and water to create a paste, apply it to the stain, let it sit for a few minutes, then scrub and rinse. Always check the manufacturer's guidelines for cleaning aluminum foil as some may have specific recommendations or restrictions.</p>

- Q: What are the most suitable materials for creating aluminum foil facing?

- <p>The best materials for making aluminum foil facing are typically aluminum alloys, specifically 1100, 3003, or 8011 series alloys. These alloys offer excellent formability, corrosion resistance, and reflectivity, which are crucial for applications like insulation, construction, and heat management. Additionally, the facing material often includes a layer of polyester or polyethylene film to enhance durability and prevent tearing. The choice of material can also depend on specific requirements such as temperature resistance, UV resistance, and environmental conditions.</p>

- Q: This question asks if there are any potential issues or risks associated with storing food in plastic containers for extended periods.

- <p>Yes, there are concerns about using plastic containers for long-term food storage. Certain plastics can leach chemicals, such as BPA (Bisphenol A) and phthalates, which may be harmful when ingested over time. These chemicals can migrate into the food, especially with exposure to heat or over extended periods. Additionally, plastic containers can break down over time, potentially releasing harmful substances into the food. It's recommended to use food-grade, BPA-free plastics or alternatives like glass containers for long-term storage to minimize health risks.</p>

- Q: Is it possible to replace plastic wrap with aluminum foil for food storage in containers?

- <p>Yes, aluminum foil can be used as a substitute for plastic wrap in food storage containers. It effectively seals in freshness and prevents air exposure, which is similar to the function of plastic wrap. However, aluminum foil is not airtight and may not be as effective in preventing the escape of odors or the entry of bacteria as plastic wrap. Additionally, it is not microwave-safe and can be less convenient for re-sealing. It's also important to ensure that the foil does not come into direct contact with acidic or alkaline foods, as this can lead to a reaction and potential contamination.</p>

- Q: This question asks for a method to create a facing made of aluminum foil.

- <p>To make your own aluminum foil facing, you'll need aluminum foil and a suitable adhesive. Start by cutting the aluminum foil to the desired size and shape. Apply a layer of adhesive to the back of the foil, ensuring it's evenly spread. Press the foil onto the surface you want to cover, smoothing out any bubbles or wrinkles. Use a knife or scissors to trim any excess foil. Allow the adhesive to dry completely before handling. This creates a reflective surface that can be used for insulation, decoration, or other purposes.</p>

Send your message to us

Aluminum Foil Facing LDPE Film Bubble Foil Roofing Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t

- Supply Capability:

- 566755 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords