Aluminum Foil Facing Double Sided Paper Foil - Roof & Wall Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Aluminum Foil Facing-DFR

Aluminum Foil Facing is a kind of film, which is made of by Aluminum foil: 7u / Tri-way fiberglass scrim: 8x12/100mm / Flame retardant adhesive /Kraft paper: 50gsm / Flame retardant adhesive / Aluminum foil: 7u

Application of Aluminum Foil Facing

Our aluminum foil facing are mainly used as facing for glass wool insulation, rockwool, mineral wool etc. Also aluminum foil facing is used under roof decking, under attic rafters, over existing attic thermal insulation, in floors, walls and crawl spaces, and in industrial and commercial buildings to block radiant heat coming into house through the roof during the summer and retain indoor heat generated during in winter

Advantage of Aluminum Foil Facing

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Packing of Aluminum Foil Facing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

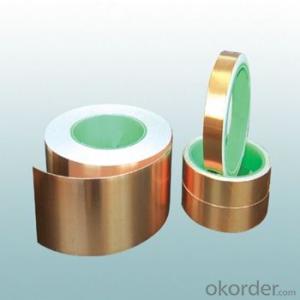

Pictures of Aluminum Foil Facing

Specification of Aluminum Foil Facing

PROPERTIES | UNIT | VALUE | TEST METHOD | |||||

Basic weight | gsm | 110 | ASTM D646 | |||||

Tensile strength: M. D. X. D. | N/25mm | 100 75 | ASTM C1136 | |||||

Burst strength | N | 35 | ASTM D774 | |||||

Reflectivity of foil surface | % | 95 | ---------- | |||||

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of Aluminum Foil Facing and is one of the large-scale professional investment Aluminum Foil Facing bases in China. Annually more than 1000 containers of Aluminum Foil Facing are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What distinguishes aluminum foil facing from other types of facing materials?

- <p>Aluminum foil facing is a type of facing material that uses a thin layer of aluminum, known for its excellent barrier properties against air, moisture, and light. This makes it ideal for insulation and packaging applications where preservation of contents is crucial. In contrast, other types of facings, such as paper, fabric, or plastic, may not offer the same level of barrier protection. Paper facings are often used for their aesthetic appeal and are more breathable, while fabric facings provide flexibility and are used for applications requiring durability and comfort. Plastic facings can be waterproof and are used where a shiny or smooth surface is desired. Each type of facing has unique properties that make it suitable for specific applications, with aluminum foil facing being particularly notable for its barrier capabilities.</p>

- Q: Is it possible for metal shavings to contaminate food when using aluminum foil with a shiny side?

- <p>There is minimal risk of metal shavings getting into food when using aluminum foil facing. Aluminum foil is designed to be safe for food contact and is generally resistant to shedding particles. However, if the foil is damaged or handled roughly, small particles could potentially come off. To mitigate this risk, ensure the foil is in good condition, avoid tearing it, and handle it carefully to prevent any metal contamination.</p>

- Q: The user is asking if it's possible to use aluminum foil as a cover for a casserole dish.

- <p>Yes, you can use aluminum foil as a cover for a casserole dish. It's a common practice to cover the dish with foil to prevent the top from drying out during baking or to keep the contents warm. Ensure the foil is food-grade and does not touch the heating elements of the oven. For best results, use heavy-duty aluminum foil to avoid punctures and tearing. Remember to remove the foil during the last few minutes of baking to allow the top to brown if desired.</p>

- Q: Is it possible to use aluminum foil facing more than once for various purposes?

- <p>Yes, aluminum foil facing can be reused for multiple purposes. It is commonly reused for cooking, baking, and food storage due to its heat resistance and reflective properties. For instance, you can use it to cover dishes in the oven, line baking sheets, or wrap food for storage. However, it's important to check for any tears or punctures after each use, as these can compromise its effectiveness and potentially lead to椋熷搧瀹夊叏 issues. Additionally, while it can be reused, it's not recommended to use it indefinitely as its performance may degrade over time.</p>

- Q: Is it possible to enhance the flavor of food by using aluminum foil facing?

- <p>Yes, using aluminum foil facing can help make food more flavorful. It can seal in moisture and steam, which helps to keep the food juicy and tender. The foil also allows for even heat distribution, which can enhance the cooking process and the development of flavors. However, it's important to note that aluminum foil should not be used with acidic foods as it can react and potentially leach into the food. Additionally, for certain dishes, direct contact with the heat source can be necessary for achieving a desired texture or flavor, so the use of foil should be considered based on the specific recipe and cooking method.</p>

- Q: Describe the most effective methods for utilizing aluminum foil in cooking.

- <p>Aluminum foil facing can be used effectively in cooking in several ways: 1) As a barrier to prevent food from sticking to the pan or grill, reducing the need for oil or butter. 2) To wrap foods for steaming, which helps retain moisture and flavor. 3) As a cover to keep food warm after cooking or to prevent overcooking. 4) To create packets for cooking fish, vegetables, or other foods en papillote, which steams the food in its own juices. 5) For baking, it can be used to line pans to prevent sticking and to make cleanup easier. 6) Foil can also be shaped into a tent to cover food during the last few minutes of cooking to prevent it from drying out. Always ensure the shiny side of the foil faces inwards when in contact with food to avoid any potential chemical reactions with the food.</p>

- Q: How should aluminum foil be properly stored when not in use to maintain its quality and usability?

- <p>The best ways to store aluminum foil when not in use include keeping it in a cool, dry place away from direct sunlight to prevent degradation. It's advisable to store it in its original box or a resealable plastic container to protect it from moisture and air exposure. Some people also use a paper towel roll as a dispenser by placing the aluminum foil around it, ensuring the shiny side is out for easy access. Keeping it in a drawer is also common, but it's important to prevent it from crumpling or tearing.</p>

- Q: What are some effective ways to use aluminum foil in the kitchen?

- <p>Using aluminum foil effectively in the kitchen can enhance cooking and cleaning. Here are some tips: 1. Line baking sheets to prevent food from sticking and to make cleanup easier. 2. Create a foil packet for cooking fish, vegetables, or meats to lock in flavors and moisture. 3. Use foil to cover dishes during baking to prevent over-browning, then remove it for the last few minutes to achieve a crispy top. 4. Create a makeshift roasting rack by folding foil to elevate meats for even cooking. 5. Use foil to wrap handles of hot pots and pans to prevent burns. 6. Polish cookware with crumpled foil and water to remove stains and scratches. 7. Use foil to create a seal when storing leftovers in containers to keep food fresh. Always handle with care and avoid using foil with acidic or alkaline foods as it can react with the foil.</p>

- Q: Is it safe to use old aluminum foil for food packaging, considering potential health risks and material degradation?

- <p>Using old aluminum foil for food packaging is not recommended. Over time, aluminum foil can become discolored, thin, or develop pinholes, which can compromise its integrity. These changes can lead to food contamination and the foil's ability to protect food from bacteria or other contaminants. Additionally, old aluminum foil may contain residues from previous uses that could mix with new food items, potentially causing off-flavors or health concerns. It's best to use fresh, clean aluminum foil for food packaging to ensure safety and hygiene.</p>

- Q: This question asks about the various types of aluminum foil facing that can be found in the market.

- <p>Aluminum foil facing is commonly used in construction for insulation and moisture protection. The different types available on the market include: 1) Plain Foil Facing, which is a simple, smooth aluminum surface; 2) Embossed Foil Facing, featuring a textured pattern for added strength; 3) Reinforced Foil Facing, which incorporates additional materials for enhanced durability; 4) Coated Foil Facing, where the aluminum is coated with other substances to improve performance; and 5) Laminated Foil Facing, which combines aluminum with other materials for specific applications. Each type serves different purposes and has unique properties that cater to various construction and industrial needs.</p>

Send your message to us

Aluminum Foil Facing Double Sided Paper Foil - Roof & Wall Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords