Thermashield Roofing Insulation - Aluminum Foil Coated Bubble Insulation FBF101

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 12000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Foil Bubble Heat Insulation

Description of Aluminum Foil Bubble:

Aluminum foil and bubble is the better product in the environmental protection, thermal insulation thermal insulation. The outermost PET has good abrasion resistance and high strength tear resistance. The bubble between the aluminum foil not only has a strong moisture, resistance oxygen, sound insulation, drop noise function, aluminum foil bubble also has very good reflective inverse heat, blocking ultraviolet.

Features of Aluminum Foil Bubble:

It is the high quality heat insulating and the invincible opponent of anti- condensation. The low and stable coefficient of heat conduction has good isolation effect.

The product has many advantages, such as light weight, heat insulation, shock absorption, sound absorption and noise reduction;

The product is easy to install and process and it also waterproof, seepage control, flame retardant.

The product also has many features, such as heat resistance, low temperature resistance, chemical resistance, ageing resistance etc.

Application of Aluminum Foil Bubble:

Building reflective heat, cold and hot water pipe insulation;

Refrigerator partition, central air conditioning, refrigerator and household appliances insulation;

Insulation, sound-absorbing, noise reduction and moisture-proof insulation in the car, train, refrigerator car, laboratory and other industries;

Special product packaging and refrigerated packing and so on

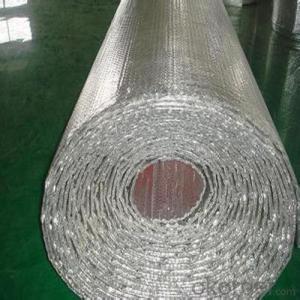

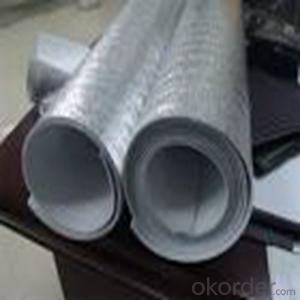

Pictures of Aluminum Foil Bubble

Specification of Aluminum Foil Bubble

STRUCTURE | ALUMINUM FOIL/BUBBLE/ALUMINUM FOIL | ALUMINUM FOIL/ BUBBLE/BUBBLE/ALUMINUM FOIL | ALUMINUM FOIL/WOVEN CLOTH/BUBBLE/WOVEN CLOTH/ALUMINUM FOIL | MPET /BUBBLE/MPET | ALUMINUM FOIL/BUBBLE/FOAM/BUBBLE/ALUMINUM FOIL |

THICKNESS | 1-4mm | 8mm | 6.5mm | 4mm | 4mm |

WEIGHT | 120GSM | 240GSM | 180GSM | 120GSM | 445GSM |

BUBBLE SIZE | 4mm HIGH x 10mm DIAMETER | 2mm HIGH x 10mm DIAMETER | 4mm HIGH x 20mm DIAMETER | 4mm HIGH x 10mm DIAMETER | 2mm HIGH x 10mm DIAMETER FOAM THICKNESS: 3.5MM |

WIDTH | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) |

THERMAL CONDUCTIVITY | 0.034w/mo | 0.032 w/mo | 0.032w/mo | 0.034w/mo | 5.87m2.k/w |

REFLECTIVITY | 96-97% | 96-97% | 96-97% | 96-97% | 96-97% |

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of aluminum foil bubble insulation,is one of the large-scale professional investment aluminum foil composite insulation bases in China, consisting of both casting foundry forging and machining factory. Annually more than 100,000 square meters foil insulation are exported to markets in Europe, America and Japan. OEM service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 20 to 25 working days can be served.

④What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

- Q: the noise when it rains is very loud. can I place an insulation material under the polycarbonate roof to reduce noise? Thanks

- Sure, depending on the roof space anyway.

- Q: Our roof tile is installed on top of galvanized iron sheets. We do not have any toher form of insulation. The roof tile or tegula is quite thick.

- Oh yeah. You need insulation. Think of it this way. If you turned a stove top burner on medium-low and placed one of those roof tiles on it, it would be too hot to pick up. If you put down a small piece of insulation first, you'd be able to pick up the tile with no problem.

- Q: we replacing our torched down rubber roof and my contractor said we need to install a 1 inch rigid insulation..is the insulation needed?

- on the outside, under the rubber? That's crazy. Don't go for it.

- Q: ... building code max. (R-50)???

- "R" I think stands for "Resistance" factor against heat loss. It resists the heat transfer but doesn't stop it. There is no such thing as perfect insulation. Snow itself is a rather good insulator. So even though you are only losing very little heat, the snow on top of the snow directly on the roof helps trap that heat at the bottom. So the first layer will melt.

- Q: My new room is an addition to a mobile home, and has a single-layer metal roof. I have 3 "main" concerns. What are the cheapest and/or most effective ways of eliminating them?1. No heat insulation- cold air sinks from the roof to my room, and my warm air rises to the roof and cools.2. Condensation forms on the inside and drips occasionally. My computer, bike, and downhill boards are in here!3. It seems like bugs could easily get into my room, but that's just a suspicion.

- welcome to the wonderful world of cheap, temporary roofing. you've just described a metal roof perfectly. bob, tell em what he's won! a lifetime supply of more bad decisions! also, the ugliest roof in town! but best of all, everyone who drives by his home will know he's a bandwagon kind of guy, he doesn't educate himself and do what's wise, he does what everyone else is doing! can't wait till that crowd finds that cliff they've been lookin for!!!

- Q: what's the best insulation for ceilling for house with semi flat roof?

- The pitch of your roof has nothing to do with the kind of insulation you should use. I recommend a fiberglass insulation that is at least 6 inches thick, the more you put in the better.

- Q: I gutted the room and now would like to rebuild. One side of the room slants (it's the roof) and the other side of the room is a dormer (all low ceilings).I want to insulate the ceiling but have no ridge vents so no moving air as someone mentioned I should have. I want to install foam channels to keep the insulation away from the roof but not sure if this is a good idea without the ridge vents. I will have a vent to the outside installed on the very top of the roof however and the small attic space is open all the way through the other two upstairs rooms and I will add another roof vent on that end of the house. I will only be able to install 3 inch insulation but that's better than none at all. I live in the northeast and was told if the job isn't done right I can get ice jams in winter. Also I don't see any way to drill ridge vents. would it be ok to just install the styrofoam channels and insulate then sheet rock or am I asking for trouble? Thanks in advance for any help.

- Suggestion: install the insulation with the foam channels but leave the center section (roof ridge area) open from end to end. At each end you can install a static vent or an active one. Depending on the amount of space you have you may be able to install a power vent.If you can send me a diagram with measurements I can give you a more definitive answer.

- Q: I already have fiberglass in the attic, but would like to add more.

- BLOWN BY ALL MEANS!!! SOME PLACES WILL EVEN LEND YOU A MACHINE TO BLOW IT WITH IF YOU BUY THE INSULATION FROM THEM.BAT TYPE INSULATION IS OLD SCHOOL!

- Q: We have plenty down at the center, so many, you can carpet a garden. So, since I'll have to tear down the roof and improve the insulation in a few months, I was thinking of adding one extra layer... of emergency blankets. Since they can reflect the sun's heat up, and the heat under it down, will they do that for a whole house? Will the plastic film cause water condensation? If you wouldn't recommend it, then what would you recommend?

- They may help, but as thin as they are, installing them would be about as easy as putting socks on a rooster!

- Q: I am thinking about getting cavity wall and roof insulation at the moment.But since summer is approaching, I fear that getting the insulation will mean that the house will be very hot at night. (During day time the house will accumulate heat from the sun, and the heat cannot escape).I also fear that the ventilation will be bad and the air in the house will not be as fresh.Any advice please?

- please stop worrying.your house will be warmer,but not hot.it is also a good idea to open your windows for at least 20 mins a day to allow claen/fresh air to circulate.you are correct in doing the job now though.

Send your message to us

Thermashield Roofing Insulation - Aluminum Foil Coated Bubble Insulation FBF101

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 12000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords