Aluminum EN AW-1050 Treadplates with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW - 1050 Aluminium Treadplates With Good Quality Description

EN AW - 1050 Aluminium Treadplates With Good Quality is one semi-finished aluminium material. The alloy AA5383 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 1050 Aluminium Treadplates With Good Quality

EN AW - 1050 Aluminium Treadplates With Good Quality | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 1050 Aluminium Treadplates With Good Quality

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 1050 Aluminium Treadplates With Good Quality

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 1050 Aluminium Treadplates With Good Quality

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

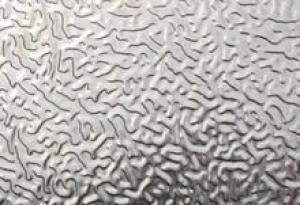

6. Image of EN AW - 1050 Aluminium Treadplates With Good Quality

7. Package and shipping of EN AW - 1050 Aluminium Treadplates With Good Quality

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for a description of the characteristics that are inherent to pure aluminum.

- <p>Pure aluminum is a lightweight, silvery-white metal known for its excellent malleability, ductility, and electrical conductivity. It has a density of 2.7 g/cm鲁, which is about one-third that of steel. It is non-magnetic and has a low melting point of 660掳C (1220掳F). Pure aluminum is also highly reflective, making it useful in mirrors and reflective coatings. It is a good thermal conductor and is resistant to corrosion due to the formation of a protective oxide layer on its surface. However, it is soft and lacks strength, which is why it is often alloyed with other elements to improve its mechanical properties.</p>

- Q: Is it possible to use aluminum as a substance that accelerates chemical reactions?

- <p>Aluminum is not typically used as a catalyst in chemical reactions. Catalysts are substances that increase the rate of a chemical reaction without being consumed in the process. Aluminum, being a metal with a +3 oxidation state, does not readily participate in reactions where it could act as a catalyst. Instead, it is more commonly used in its elemental form for structural purposes or as a reducing agent in certain chemical processes. However, aluminum compounds, such as alumina (Al2O3), can be used as catalysts or catalyst supports in specific industrial applications.</p>

- Q: This question asks about the chemical reaction between aluminum and elements in the halogen group.

- <p>Aluminum reacts with halogens to form aluminum halides. The reaction is typically exothermic and can be represented by the general equation: 2Al + 3X2 鈫?2AlX3, where X represents a halogen (fluorine, chlorine, bromine, iodine, or astatine). For example, when aluminum reacts with chlorine, it forms aluminum chloride (AlCl3). The reaction is often initiated by heating the aluminum, which is then rapidly oxidized by the halogen. This process is used industrially to produce aluminum halides, which are important in various chemical applications.</p>

- Q: Describe the environmental impact of discarded aluminum.

- <p>Discarded aluminum can have significant environmental impacts. It contributes to land and water pollution, as it does not biodegrade and can leach harmful substances into the soil and water. Additionally, aluminum can disrupt the food chain when ingested by wildlife, potentially leading to health issues. The production of aluminum is energy-intensive, so recycling it reduces the demand for raw materials and decreases greenhouse gas emissions. However, improper disposal can lead to the release of toxic substances during the recycling process, further harming the environment.</p>

- Q: What is the chemical formula that represents aluminum?

- <p>The chemical formula for aluminum is Al. It is a lightweight, silvery-white metal that is found in the Earth's crust and is the most abundant metal there. Aluminum is a member of the boron group of chemical elements and is represented by the symbol Al, which is derived from the Latin word 'alumen', meaning alum.</p>

- Q: This question asks for examples of industrial processes that incorporate the use of aluminum.

- <p>Aluminum is widely used in various industrial processes due to its lightweight, corrosion resistance, and high strength-to-weight ratio. Some key industrial processes that utilize aluminum include the automotive industry for manufacturing car parts, the aerospace industry for aircraft construction, the construction industry for building materials, the packaging industry for food and beverage cans, and the electronics industry for components in devices. Aluminum is also used in the manufacturing of machinery, electrical equipment, and transportation equipment. Its versatility makes it a crucial material in many industrial applications.</p>

- Q: Jiangsu in addition to the 10000 aluminum factory, there are no other aluminum factory?

- Jiangyin Xinyu company specializing in the production of various types of building Aluminum Alloy industrial profiles, A Well-Known Trademark in China, national inspection, Jiangsu famous brand, my ID address after the two to 52 is my mobile phone number, welcome to contact with us, thank you!

- Q: What are the elements that make up aluminum oxide and what is its chemical formula?

- <p>Aluminum oxide is composed of aluminum and oxygen. Its chemical formula is Al2O3, indicating that it consists of two aluminum atoms (Al) and three oxygen atoms (O). This compound is a widely used industrial material, known for its high melting point and hardness.</p>

- Q: This question asks about the amount of energy needed to produce aluminum, including the process and factors that influence energy consumption.

- <p>Producing aluminum requires a significant amount of energy, primarily due to the electrolytic process used to extract it from its ore, bauxite. The Hall-H茅roult process, the most common method, consumes about 15,000 to 16,000 kilowatt-hours of electricity per ton of aluminum produced. This high energy demand is largely due to the strong chemical bonds in aluminum oxide, which must be broken to release the aluminum. Energy consumption can vary based on the efficiency of the smelting process, the quality of the bauxite, and the energy source used, with renewable energy potentially reducing the carbon footprint but not necessarily the total energy input.</p>

- Q: Are aluminum alloys suitable for use in the aerospace industry?

- <p>Yes, aluminum alloys are extensively used in aerospace applications due to their high strength-to-weight ratio, corrosion resistance, and good fatigue characteristics. They are particularly favored for constructing airframes, wings, and other structural components where weight savings are critical. The alloys are also used in manufacturing engine parts and heat exchangers due to their thermal conductivity and ability to withstand high temperatures. However, the specific alloy selection depends on the particular requirements of the application, such as temperature resistance, strength, and environmental conditions.</p>

Send your message to us

Aluminum EN AW-1050 Treadplates with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches