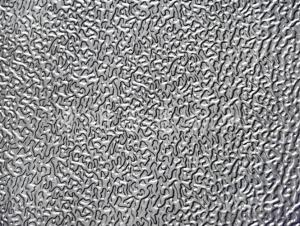

Aluminum Colored Plastic Sheets - Embossed/Coated Alloy Aluminum Coil with Various Patterns

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1 Specifications of Stucco Embossed Coated Aluminium Coil

Alloy | AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-1.50mm |

Width: | 10mm- 1300mm |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

2 Full set of process

Professional slitting line,to divide the coil into any width ,with accuracy +-0.02mm;

Professional cutting line,to make sheet with any length;

Embossed line could process aluminum coil with max thickness (1.0mm of A5754H24);

Brushing line,to make the coil brushed as required;

Full-set processing for food-grade aluminum coil and sheet.

3 Sufficient Raw-materials in Stock

To make an shorter lead-time ,lidao hold in stock around 5000tons of aluminum coil mill finishing ,

in alloy A1,A3,or A5 series;with thickness from 2.0mm to 3.0mm width from 1000mm to 2400mm

also approx 2000tons of coated aluminum coil and sheet ,As VIP customers of our suppliers ,we

could always get the raw-materials as soon as possible.

4 Stable and Reliable Quality

Aimed at first-classed market, CNBM Alu. get the raw materials from few excellent supplier like South Western Aluminum, CHALCO, NanShan Aluminum, Suimin and some from Novelis or ALCOA,the coating lacquer are mainly from PPG ,Becker,or Valspar. Aimed at long term cooperation ,Lidao works with professional Quality-inspection term that keeping online 24 hours ,to make completely strick inspection and detailed record on each coil.

5 Our Services

1. Reply you any question within 24 hours.

2. 7 days per week, 24 hours per day available.

3. Sample and more information are avaliable for the client at any time

4. After sale service

- Q: Explain the similarities and differences in the properties of aluminum metal, Al(s) and aluminum oxide (a salt) Al203(s) in terms of the particles and forces present.. thanks doods!

- Aluminum metal is not found in nature, only aluminum oxide is in the mine or ground and they have to separate it from the oxidation to make a useful metal.

- Q: Describe the steps involved in the production of aluminum sheets.

- <p>The process of manufacturing aluminum sheets involves several key steps. Initially, raw materials, primarily bauxite, are mined and then processed to extract alumina (aluminum oxide). This alumina is then mixed with cryolite and fed into a reduction cell where it is subjected to a strong electric current, causing the aluminum to be reduced and extracted. The molten aluminum is then poured into molds to cool and solidify into ingots. These ingots are subsequently rolled into sheets in a hot or cold rolling process, where they are gradually reduced in thickness and width. The sheets are then annealed to improve their ductility and strength. Finally, they undergo various finishing processes such as cleaning, coating, or cutting to meet specific requirements before being packaged and shipped to customers.</p>

- Q: Can aluminum sheets be embossed or textured?

- Yes, aluminum sheets can be embossed or textured. The process of embossing or texturing aluminum sheets involves creating patterns or designs on the surface by pressing or rolling the sheet with specialized machinery. This can be done to enhance the aesthetic appearance of the sheet or to improve its functionality, such as adding grip or increasing strength. Embossed or textured aluminum sheets are commonly used in various industries, including automotive, interior design, and packaging.

- Q: Are aluminum sheets suitable for use in cryogenic environments?

- Yes, aluminum sheets are suitable for use in cryogenic environments. Aluminum has excellent thermal conductivity, low density, and good mechanical properties at low temperatures, making it an ideal choice for applications in cryogenic environments. Additionally, aluminum has a low coefficient of thermal expansion, which allows it to maintain its structural integrity even under extreme temperature fluctuations.

- Q: This question asks whether it is possible to utilize stamped or embossed aluminum sheets for a specific project.

- <p>Yes, you can use stamped or embossed aluminum sheets in your project. These sheets are known for their strength, durability, and lightweight properties, making them ideal for various applications such as construction, automotive, and aerospace. Stamped aluminum sheets are formed by pressing the material into a specific shape, while embossed sheets have a raised pattern. Both types offer design flexibility and can be customized to meet specific project requirements. Ensure that the aluminum sheets you select meet the necessary specifications for your project, such as thickness, strength, and finish.</p>

- Q: Can aluminum sheets be used for structural purposes?

- Indeed, structural purposes can be fulfilled by utilizing aluminum sheets. This material, known for its lightness and remarkable malleability, can be effortlessly shaped and sized in diverse forms. Thanks to its exceptional strength-to-weight ratio, it is an ideal choice for structural applications that prioritize weight reduction. In industries such as aerospace, automotive, and construction, aluminum sheets are commonly employed to create structural components like panels, beams, and frames. Moreover, the corrosion resistance of aluminum adds to its suitability for structural purposes, particularly in outdoor or marine settings. Ultimately, aluminum sheets present a dependable and economical solution for structural applications.

- Q: Can aluminum sheets be used for signage?

- Signage can indeed utilize aluminum sheets. Aluminum, a versatile and durable material, is frequently employed in the sign-making industry. Its lightweight yet sturdy properties make it well-suited for both outdoor and indoor signage. Additionally, aluminum sheets are resistant to corrosion, rust, and fading, guaranteeing signage longevity. They can also be easily cut and shaped into various sizes and designs, providing creative and customized signage solutions. Furthermore, the material offers a smooth surface that can be painted, printed, or laminated with graphics and text, making it highly adaptable for different signage applications. In conclusion, due to their durability, versatility, and aesthetic appeal, aluminum sheets are a favored choice for signage.

- Q: aluminum is produced by breaking down the compound...

- Bauxite is the most important aluminum ore. It consists largely of the minerals gibbsite Al(OH)3, boehmite γ-AlO(OH), and diaspore α-AlO(OH), together with the iron oxides goethite and hematite, the clay mineral kaolinite and small amounts of anatase TiO2. You have an unusual way of asking that question. Aluminum is an element and cannot be broken down accept to sub-atomic particles.

- Q: Are the aluminum sheets suitable for manufacturing kitchen backsplashes?

- Yes, aluminum sheets are suitable for manufacturing kitchen backsplashes. Aluminum is a durable and lightweight material that is resistant to rust and corrosion, making it ideal for use in kitchen environments. Additionally, aluminum sheets can be easily cut and shaped to fit various design preferences, providing a sleek and modern look to any kitchen backsplash.

- Q: What are the aluminum plates for?

- The products are widely used in construction, curtain wall, packaging, food, air conditioners, refrigerators, solar energy, automobile manufacturing, ship manufacturing, machinery manufacturing, cosmetics packaging and other electrical appliances, machinery manufacturing industry, can also be used in power plants, chemical and petrochemical industry factory anticorrosion & insulation etc..Shandong Pingyin Hengshun Aluminium Co., Ltd. specializing in the production of (hot rolling, cold rolling aluminum alloy) roll. Aluminum coil. Alloy aluminum. Aluminum. Ultra wide / ultra thick aluminium alloy. Sawing, shearing customer requirements specification aluminum alloy thick aluminum wire, aluminum, aluminum flange with aluminum, power plant / chemical anticorrosion and insulation alloy factory aluminum moisture-proof aluminum roll roll.

Send your message to us

Aluminum Colored Plastic Sheets - Embossed/Coated Alloy Aluminum Coil with Various Patterns

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords