Aluminum Coil Printing - Color Coated Aluminium Coil PVDF Painting for Outer Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Aluminium Coil PVDF painting for Outer Doors

Material | Alloy Aluminum 1XXX,3XXX,5XXX or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating,PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Color Coated Aluminium Coil PVDF painting for Outer Doors

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminium Coil PVDF painting for Outer Doors

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

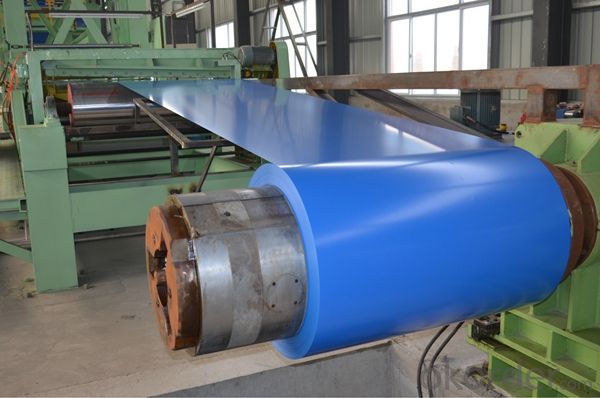

5. Image of Color Coated Aluminium Coil PVDF painting for Outer Doors

6. Package and shipping of Color Coated Aluminium Coil PVDF painting for Outer Doors

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do aluminum coils contribute to energy-efficient appliance manufacturing?

- Aluminum coils contribute to energy-efficient appliance manufacturing by offering several key advantages. Firstly, aluminum is a lightweight material that reduces the overall weight of appliances, making them easier to transport and reducing energy consumption during transportation. Secondly, aluminum has excellent heat transfer properties, allowing for more efficient heat exchange in appliances like refrigerators, air conditioners, and heat pumps. This leads to improved energy efficiency and reduced electricity consumption. Additionally, aluminum coils are highly durable and resistant to corrosion, ensuring longer appliance lifespans and minimizing the need for replacements. Overall, the use of aluminum coils in appliance manufacturing plays a significant role in enhancing energy efficiency and reducing environmental impact.

- Q: Can aluminum coils be used in agricultural applications?

- Yes, aluminum coils can be used in agricultural applications. Aluminum is a versatile and durable material that can withstand various environmental conditions, making it suitable for agricultural equipment such as irrigation systems, greenhouse structures, and ventilation systems. Additionally, aluminum's light weight and corrosion-resistant properties make it an ideal choice for agricultural applications where durability and long-term performance are essential.

- Q: What are the vibration damping properties of aluminum coils?

- Aluminum coils have excellent vibration damping properties, making them an ideal choice for various applications that require vibration control. Due to their high stiffness and low density, aluminum coils effectively absorb and dissipate vibrations, reducing the amplitude and frequency of oscillations. This vibration damping ability is beneficial in industries such as automotive, aerospace, and electronics, where minimizing vibration is crucial for performance, durability, and overall user experience. Additionally, aluminum coils' ability to dampen vibrations helps to reduce noise levels, leading to quieter operations and environments. Overall, aluminum coils' vibration damping properties contribute to improved product performance, increased safety, and enhanced user comfort.

- Q: What are the standard widths of aluminum coils?

- The specific industry and application play a role in determining the varying standard widths of aluminum coils. Generally, aluminum coils come in widths ranging from 12 inches (30.48 cm) to 60 inches (152.4 cm). These widely accepted widths are commonly utilized in construction, transportation, and manufacturing sectors. It is worth mentioning that customized widths are also readily accessible to meet specific project needs in the market.

- Q: Almost every restaraunt uses aluminium foils and polyehylene for packing foods - that you carry to home.How safe is this ?For how long would the temperature be mainitained ?and within what time if consumed and is it safe ?

- yes! its completely safe. well untill the food gets rotten its safe to consume food covered in aluminium foil.It doesnt spoil food and it does keep the food hot depending on te temperature of food and the weather outside.

- Q: Can aluminum coils be used for roofing applications?

- Absolutely! Roofing applications can definitely make use of aluminum coils. Aluminum is widely preferred as a roofing material owing to its array of benefits. Its lightweight nature simplifies transportation and installation processes. Additionally, aluminum boasts exceptional durability and resistance against corrosion, guaranteeing an extended lifespan for the roof. Furthermore, it is an ideal choice for regions with high humidity or coastal areas, as it does not succumb to rust. Moreover, aluminum roofing proves to be energy-efficient as it effectively reflects sunlight and heat, thus reducing cooling expenses. All in all, thanks to their robustness, longevity, and energy efficiency, aluminum coils make an outstanding choice for roofing applications.

- Q: What are the weight ranges of aluminum coils?

- The weight ranges of aluminum coils can vary depending on the specific application and industry. However, in general, aluminum coils can range from a few hundred pounds to several thousand pounds in weight.

- Q: Can aluminum coils be used in electrical busbars?

- Yes, aluminum coils can be used in electrical busbars. Aluminum offers good conductivity, is lightweight, and cost-effective, making it suitable for use in busbars. However, proper insulation and connection techniques must be employed to address the higher thermal expansion and potential corrosion issues associated with aluminum.

- Q: If the aluminum coil is 220 kg, 0.3 thick and 500 wide, how much is the coil diameter?

- With the outer diameter and inner diameter, you can know the volume. With the density and volume, we can calculate the weight. And with weight, we can know the length.

- Q: what is the most likely charge for aluminum cation?the answer is +3, but why? how can i figure this out with different ones?

- Aluminum has 3 valence electrons and it will try to get rid of these to end up with the outer valence shell being full. Electrons have a negative charge though, so getting rid of one brings the actual charge up, so it ends up +3.

Send your message to us

Aluminum Coil Printing - Color Coated Aluminium Coil PVDF Painting for Outer Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords