Wholesale Aluminum Metal Sheets for Beverage Can Lids

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Coil and Sheet for Beverage Can Lids Description:

Aluminum Coil and Sheet for Beverage Can Lidsadopt Japan original painting machine and PPG coating that is exclusively used for tank cap, and professionally produces the coated aluminium coils used for making ring-pull and lid of pop can. All the products are tested by the special instrument, and have passed the FDA recognition of the US. Hot Rolling Thick Aluminum Sheets are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Aluminum Coil and Sheet for Beverage Can Lids:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

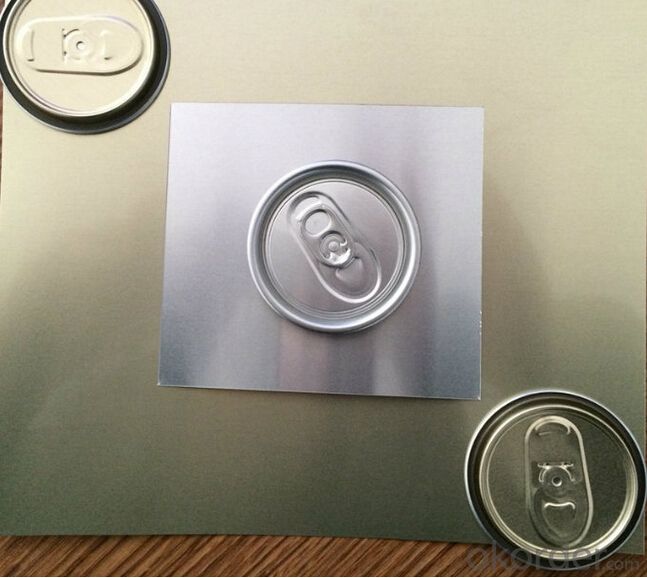

3. Aluminum Coil and Sheet for Beverage Can Lids Images:

4. Aluminum Coil and Sheet for Beverage Can Lids Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: How to distinguish aluminum sheet from magnesium sheet?

- put them into acid and observe bubble's generating speed, the quicker one is magnesium sheet.

- Q: How is the strength and durability of aluminum sheets determined?

- The strength and durability of aluminum sheets are determined through a variety of testing methods and parameters. One of the primary factors that determines the strength of aluminum sheets is the alloy composition. Different alloy compositions have varying levels of strength, and certain elements added to the aluminum can enhance its strength properties. To evaluate the strength of aluminum sheets, tensile testing is commonly employed. This involves subjecting a sample of the sheet to tension until it fractures. During the test, the load and deformation are measured, and the ultimate tensile strength (UTS) and yield strength are determined. UTS represents the maximum stress the sheet can withstand before failure, while yield strength is the stress at which the material begins to deform plastically. Another important consideration for determining the strength and durability of aluminum sheets is the thickness. Generally, thicker sheets tend to be stronger and more durable than thinner ones due to the increased cross-sectional area contributing to load-bearing capacity. In addition to alloy composition and thickness, the manufacturing process also affects the strength and durability of aluminum sheets. Factors such as rolling and heat treatment can alter the microstructure of the aluminum, influencing its mechanical properties. Proper control of these processes helps ensure consistent strength and durability across the sheets. Furthermore, aluminum sheets are often evaluated for their resistance to corrosion. Aluminum naturally forms a protective oxide layer, which contributes to its corrosion resistance. However, specific coatings or treatments can be applied to enhance this resistance, depending on the intended application. In summary, the strength and durability of aluminum sheets are determined through a combination of alloy composition, thickness, manufacturing processes, and testing methods such as tensile testing. These factors collectively dictate the mechanical properties and resistance of aluminum sheets to various forms of stress, making them suitable for a wide range of applications.

- Q: Explain how aluminum sheets impact the soundproofing capabilities of a building.

- <p>Aluminum sheets can have a significant impact on the sound insulation of a building. They are often used as a cladding material due to their durability and low maintenance requirements. However, aluminum is a good conductor of sound, which means it can transmit sound waves efficiently. This can reduce the sound insulation of a building, especially if the aluminum sheets are not combined with other soundproofing materials. To improve sound insulation, aluminum sheets can be combined with insulation materials, such as polyurethane foam, to create a barrier that reduces sound transmission. Additionally, using thicker aluminum sheets or adding a layer of sound-absorbing material can help enhance the soundproofing capabilities of a building.</p>

- Q: why does the bubble apear a few minutes later after putting aluminum sheet into dilute sulphuric acid?

- Because there is oxide on the surface of aluminum, the reaction will be quicker after polishing the oxide with abrasive paper.

- Q: im doing a science project on aluminum and i need to know if aluminum is combustible or not. I was reading a website and they said that it reacts when its the right temperature? i really have no idea what the answer is please help! :)

- Aluminum metal oxidizes readily in air but when that happens, a layer of aluminum oxide will form, preventing further oxidation. So if you have a block of aluminum, the surface will oxidize and the rest will not. If you shave aluminum into a fine powder, you can actually light it on fire as it will rapidly and violently oxidize because there is more surface area. If you add iron powder in the mix, it will burn even hotter. I would not recommend doing this reaction.

- Q: Can aluminum sheets be used for packaging applications?

- Yes, aluminum sheets can be used for packaging applications. Aluminum is a lightweight, corrosion-resistant, and durable material, making it an excellent choice for packaging various products. It provides a barrier against moisture, oxygen, and light, which helps to preserve the quality and freshness of the packaged goods. Aluminum sheets can be easily formed into different shapes and sizes, allowing for customization and branding options. They are commonly used for packaging food and beverages, pharmaceuticals, cosmetics, and other consumer goods. Additionally, aluminum sheets are recyclable, making them a sustainable choice for packaging applications.

- Q: What is the corrosion resistance of 101 aluminum sheets in saltwater environments?

- The corrosion resistance of 101 aluminum sheets in saltwater environments is generally considered to be good. However, prolonged exposure to saltwater can still cause some level of corrosion over time.

- Q: Can aluminum sheets be an alternative to wood in certain applications?

- Certainly, aluminum sheets can serve as a viable substitute for wood in specific applications. Aluminum boasts numerous advantages over wood, rendering it a favored choice across various industries. Primarily, aluminum exhibits exceptional durability and longevity due to its resistance to corrosion, rot, and pests. Consequently, it proves ideal for outdoor usage or areas with high moisture levels. Moreover, aluminum sheets are lightweight, facilitating easier handling and transportation in comparison to wood. Additionally, they possess a commendable strength-to-weight ratio, enabling them to withstand heavy loads while maintaining their structural integrity. Moreover, aluminum stands as a sustainable material, capable of indefinite recycling without compromising its properties. Conversely, wood necessitates the felling of trees, thereby carrying environmental implications. Aluminum sheets also offer a high degree of design flexibility, readily assuming complex structures through shaping, bending, and forming. This adaptability allows for innovative and creative applications. Furthermore, aluminum exhibits excellent thermal and electrical conductivity, rendering it suitable for scenarios where heat dissipation or electrical conductivity plays a crucial role. Nonetheless, it is crucial to acknowledge that wood retains its unique characteristics and benefits in certain applications. Wood imparts a warm and natural aesthetic that aluminum fails to replicate, making it a preferred choice in interior design or furniture manufacturing. Additionally, wood qualifies as a renewable resource and exhibits excellent insulation properties, proving advantageous in construction or insulation applications. Consequently, while aluminum sheets can serve as a fantastic substitute for wood in numerous instances, the ultimate choice hinges upon the specific requirements and desired outcomes of the application at hand.

- Q: What precautions should be taken while handling aluminum sheets to ensure safety?

- <p>When working with aluminum sheets, it's important to take certain safety measures. Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to protect against sharp edges and metal dust. Ensure good ventilation to avoid inhaling aluminum dust, which can be harmful. Use proper tools designed for metal work to prevent accidents. Keep the work area clean and free from clutter to minimize trip hazards. Be cautious of electrical hazards if using power tools, and ensure all tools are in good working order. Finally, be aware of the fire hazard potential of aluminum, especially when cutting or welding, and have fire extinguishers readily available.</p>

- Q: Are aluminum sheets resistant to abrasion?

- Yes, aluminum sheets are generally resistant to abrasion. Aluminum is known for its durability and strength, making it resistant to scratches or damage caused by abrasion. However, the level of resistance may vary depending on the specific alloy and thickness of the aluminum sheet. Thicker sheets with higher alloy content tend to provide better resistance against abrasion. Additionally, the surface finish of the aluminum sheet can also play a role in its resistance to abrasion. Overall, aluminum sheets are a reliable choice when it comes to withstanding abrasion in various applications.

Send your message to us

Wholesale Aluminum Metal Sheets for Beverage Can Lids

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords