6061 Aluminum Coils for Sale - 1200 Aluminum Alloy Coil H112 Temper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

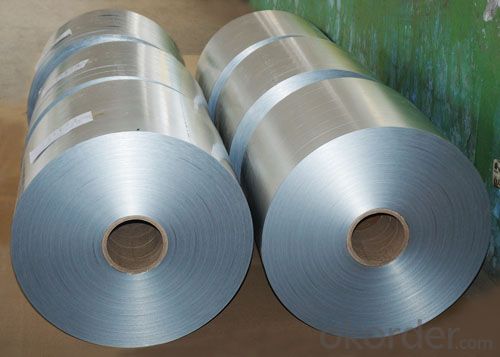

Aluminum Coil 1200 Aluminum Alloy Coil H112 Temper

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: Can aluminum coils be used in the manufacturing of appliances?

- Yes, aluminum coils can be used in the manufacturing of appliances. Aluminum coils offer several advantages such as being lightweight, corrosion-resistant, and having good thermal conductivity, making them suitable for various appliance applications including refrigerators, air conditioners, and heating systems.

- Q: my text says aluminium does not corrode much as a passive aluminium oxide layer is formed on it.Well other metals such as sodium adn potassium also form oxides. Why dont their oxides prevent further oxidation ?

- sodium oxide and potassium oxide are water soluble aluminium oxide is not water soluble. the layer formed of oxide on the aluminium surface is coherent and adherent with no pores and stuck to the metal surface. the layer is also passive to most acids and alkalies except HCl and anti passive ions if present. sodium oxide and potassium oxide dissolve in any aqueous medium forming the corresponding alkalies NaOH and KOH leaving the fresh metal surface exposed to more corrosion. also the reaction of Na and K with aqueous media like water and acids is quite vigorous and fast unlike aluminium which is mu less reactive

- Q: What are the different packaging options for aluminum coils?

- There are several different packaging options for aluminum coils, including wooden crates, cardboard boxes, shrink wrap, and stretch wrap. These packaging options help protect the coils from moisture, dust, and physical damage during transportation and storage. Additionally, some suppliers may offer customized packaging solutions to meet specific requirements and ensure the safe delivery of aluminum coils.

- Q: What is the maximum yield strength of aluminum coils?

- The maximum yield strength of aluminum coils can vary depending on the specific alloy and temper of the aluminum. However, in general, aluminum coils typically have a yield strength ranging from 10,000 to 40,000 psi (pounds per square inch). It is important to note that different alloys and tempers of aluminum have different properties and therefore different maximum yield strengths. Additionally, the thickness and width of the aluminum coils can also affect their maximum yield strength. Therefore, it is recommended to consult the manufacturer's specifications or standards for the specific alloy and temper of the aluminum coils to determine their maximum yield strength.

- Q: This question asks about the various classifications of aluminum coil based on their properties and applications.

- <p>Aluminum coils are categorized into different grades based on their alloy composition and applications. The most common grades include 1000 series (99% pure aluminum), 3000 series (aluminum-manganese alloys), 5000 series (aluminum-magnesium alloys), and 6000 series (aluminum-magnesium-silicone alloys). Each grade has unique properties such as formability, strength, and corrosion resistance, which make them suitable for specific applications like construction, transportation, and packaging. The selection of the grade depends on the performance requirements of the end product.</p>

- Q: the ingredient on the back says aluminum?also ..what is sodium benzoate?Is all this stuff that terrible for you? Or does it mean something else?

- The aluminum is in the baking powder. Very common but you can buy it without it, it is much healthier for you. Aluminum is correlated to Alzheimer's and ADD. Baked goods taste much better without the aluminum too. Benzoate of soda, a preservative that can alter your DNA. Not too good for you, no matter what the FDA may say about it. All told, if you are concerned for your health, keep to organic as much as possible and made from scratch too. Way too much junk is put in our food and health products.

- Q: Is it possible to utilize aluminum coils in creating art pieces or decorative items?

- <p>Yes, aluminum coils can be used to make artworks or decorations. Aluminum's malleability and durability make it an excellent material for crafting. It can be bent, twisted, and shaped into various forms, allowing for creative expression in art and design. Additionally, aluminum's resistance to corrosion and weathering makes it suitable for both indoor and outdoor decorative pieces. Artists often appreciate its lightweight nature and the metallic finish that can be polished or painted, offering versatility in artistic applications.</p>

- Q: Are aluminum coils suitable for low-maintenance roofing applications?

- Indeed, low-maintenance roofing applications can benefit from the suitability of aluminum coils. Renowned for its durability, longevity, and corrosion resistance, aluminum proves to be an ideal roofing material. Despite its lightweight nature, aluminum coils possess remarkable strength that ensures superior structural integrity, enabling them to endure diverse weather conditions. Moreover, aluminum's low-maintenance characteristics make it a standout choice. It does not rust and does not necessitate regular painting, allowing homeowners and building managers to save valuable time and money that would otherwise be spent on maintenance tasks such as repainting or replacing rusted components. Ultimately, aluminum coils serve as an outstanding option for low-maintenance roofing applications.

- Q: What exactly happens in the reaction involving powdered aluminum and crushed iodine? I know that adding a few drops of water produces a lot of purple smoke and that it will flare up but what is the chemistry involved? And also, I know that the white residual left in the cup is Al2I6 but why is it acidic when water is added to it? It has a pH of between 1 and 2. What is the smoke that is produced and what causes the exothermic reaction?

- This Site Might Help You. RE: aluminum, iodine and water? What exactly happens in the reaction involving powdered aluminum and crushed iodine? I know that adding a few drops of water produces a lot of purple smoke and that it will flare up but what is the chemistry involved? And also, I know that the white residual left in the cup is Al2I6 but why is it...

- Q: Can aluminum coils be used in high-temperature applications?

- Indeed, high-temperature applications can make use of aluminum coils. With its melting point reaching 660 degrees Celsius (1220 degrees Fahrenheit), aluminum proves itself as a fitting option for diverse high-temperature settings. Furthermore, its remarkable thermal conductivity enables efficient heat transfer, rendering it a favored selection for heat exchangers and HVAC systems. Nevertheless, it is crucial to acknowledge that the particular application and temperature needs must be taken into account, as exceedingly high temperatures surpassing aluminum's melting point might necessitate alternative materials.

Send your message to us

6061 Aluminum Coils for Sale - 1200 Aluminum Alloy Coil H112 Temper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords