Aluminum Window Strips for Automotive Alloys in Roll Shutter with Different Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Automotive alloys...

(2).Air and gas cylinders...

(3).Aluminium compounds...

3. Feature of Aluminum

The liquid aluminium metal sinks to the bottom of the solution and is tapped off, usually cast into large blocks called aluminium billets for further processing. The carbon anode is consumed by reaction with oxide to form carbon dioxide gas. A small quantity of fluoride compounds flow with this gas. In modern smelters, this hot carbon dioxide gas is filtered through alumina to remove fluorine compounds and return hydrogen fluoride as aluminium fluoride to theelectrolytic cells.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

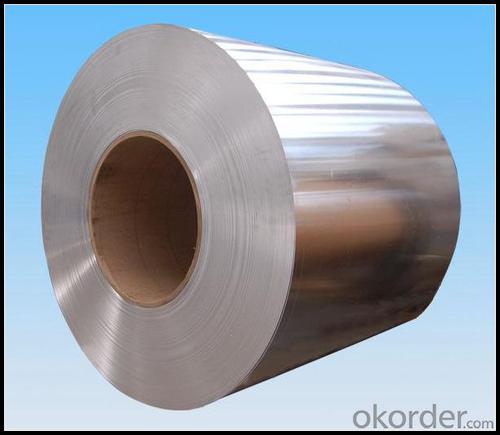

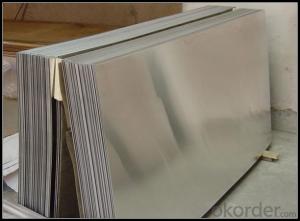

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: This question asks about the impact of temperature on the performance of aluminum strips used in construction.

- <p>Temperature significantly affects the performance of aluminum strips in construction. At low temperatures, aluminum becomes more brittle, reducing its ductility and increasing the risk of cracking or breaking under stress. Conversely, high temperatures can cause aluminum to lose strength and become more susceptible to deformation. It's crucial to maintain optimal working temperatures to ensure the structural integrity and longevity of aluminum components. Additionally, temperature fluctuations can lead to thermal expansion and contraction, affecting the fit and alignment of aluminum strips, potentially causing gaps or misalignments in constructions.</p>

- Q: What characteristics of aluminum strips make them ideal for construction purposes?

- <p>Aluminum strips are suitable for use in construction due to several key properties. They are lightweight, which reduces the load on structures and makes them easier to handle and install. They possess high strength-to-weight ratio, ensuring durability and resistance to deformation. Aluminum strips are also corrosion-resistant, protecting against rust and other forms of decay, which is crucial for long-term structural integrity. Their excellent thermal conductivity aids in heat management, which is beneficial in both heating and cooling applications. Furthermore, aluminum strips are malleable and can be easily shaped and bent, allowing for versatile design and construction. Lastly, they are recyclable, contributing to sustainability and reducing environmental impact.</p>

- Q: What are the elements and compounds that make up aluminum strips?

- <p>Aluminum strips are primarily composed of the element aluminum (Al), which is a lightweight, silvery-white, and malleable metal. Aluminum is a pure element and not a compound, so its composition is straightforward. It is found in Group 13 of the periodic table and has an atomic number of 13. In its pure form, aluminum is soft and lacks sufficient strength for many applications, so it is often alloyed with other elements such as copper, magnesium, manganese, silicon, and zinc to improve its strength and durability. These alloying elements can make up a small percentage of the total composition, but they significantly enhance the properties of the aluminum strips for various industrial uses.</p>

- Q: What constitutes the primary substance of aluminum strips?

- <p>Aluminum strips are primarily made from aluminum, a lightweight and malleable metal known for its high conductivity and resistance to corrosion. They are typically composed of pure aluminum or aluminum alloys, which may include elements such as copper, magnesium, manganese, or silicon to enhance specific properties like strength or durability. These strips are widely used in various industries due to their versatility and the metal's beneficial characteristics.</p>

- Q: What are the potential dangers or issues that could arise from using adhesive to attach aluminum strips?

- <p>Using adhesive to install aluminum strips can involve certain risks. These include the possibility of the adhesive failing over time, leading to the strips becoming loose or falling off. There's also a risk of the adhesive damaging the surface it's applied to, especially if it's not removed carefully or if it's a sensitive material. Additionally, improper installation can lead to an uneven or unattractive finish. It's important to use a high-quality adhesive suitable for the material and follow the manufacturer's instructions to minimize these risks.</p>

- Q: Is it possible to apply paint to aluminum strips?

- <p>Yes, aluminum strips can be painted. However, proper surface preparation is crucial for good adhesion and durability of the paint. This typically involves cleaning the aluminum to remove any grease or contaminants, followed by etching or using a primer designed for aluminum to promote better paint adherence. After priming, the aluminum can be painted with a suitable paint, such as acrylic or epoxy, which are known for their compatibility with metal surfaces. It's important to follow the manufacturer's instructions for the specific paint and primer used to ensure the best results.</p>

- Q: Is it possible to use recycled adhesive to attach aluminum strips?

- <p>Using recycled adhesive to install aluminum strips is generally not recommended. Recycled adhesive may have reduced adhesive properties due to previous use, which could compromise the bond's strength and durability. It's crucial to use a new adhesive specifically designed for the material and application to ensure a secure and long-lasting installation. Always follow the manufacturer's guidelines for the best results.</p>

- Q: Describe how the weight of an aluminum strip compares to other common roofing materials.

- <p>An aluminum strip is significantly lighter than many other roofing materials. It weighs approximately 1.5 to 2.5 pounds per square foot, depending on the thickness and profile. In contrast, asphalt shingles can weigh between 2.5 to 4.5 pounds per square foot, while concrete tiles can be as heavy as 7 to 10 pounds per square foot. Clay tiles are also heavier, typically ranging from 6 to 8 pounds per square foot. This makes aluminum strips an attractive option for those seeking a lightweight roofing solution.</p>

- Q: What are the cost differences between aluminum and aluminum strips?

- <p>Aluminum and aluminum strips are both made from the same base material, but their costs can differ due to several factors. Aluminum strips are typically more expensive than bulk aluminum due to the additional processing and manufacturing steps involved in creating them. These steps include rolling, cutting, and sometimes surface treatments, which add to the cost. Additionally, aluminum strips often have tighter tolerances and specific dimensions, which can also increase their price. However, the exact cost difference can vary based on factors such as market prices for aluminum, the complexity of the strip's specifications, and the quantity purchased.</p>

- Q: Explain how aluminum strips play a role in enhancing energy efficiency.

- <p>Aluminum strips contribute to energy efficiency primarily through their use in thermal insulation and reflective properties. In building construction, aluminum strips can be used to create airtight seals around windows and doors, reducing heat transfer and drafts, which in turn lowers the need for heating or cooling systems. Additionally, aluminum's reflective nature can be utilized in radiant barriers, which reflect heat away from buildings, reducing the energy required for cooling. In electrical applications, aluminum strips are used in high-efficiency transformers and electrical conductors due to their high conductivity and light weight, reducing energy loss during transmission. Overall, aluminum strips enhance energy efficiency by minimizing heat loss and improving the performance of energy systems.</p>

Send your message to us

Aluminum Window Strips for Automotive Alloys in Roll Shutter with Different Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords