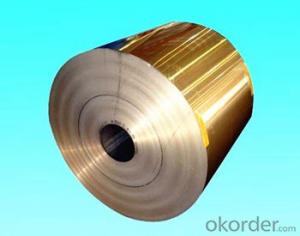

Aluminum Air-Conditioner Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 MT m.t.

- Supply Capability:

- 7000MT/MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick details of aluminum foil for air-conditionor

Alloy: 8011/1100/1235

Temper: O/H18/H22/H24/H26

Specifications of aluminum foil for air-conditionor

Thickness & Tolerance: 0.007mm-0.2mm (±6%)

Width & Tolerance: 200mm-1650mm (±1mm)

Mechancial Properties: Tensile Strength(U.T.S)≥80Mpa, Elongation≥1%

Standard: GB/T3198 / ASTM-B209 / EN546

Usage/Application of aluminum foil for air-conditionor

For for air-conditionor

Packaging & Delivery of aluminum foil for air-conditionor

Packing: seaworthy wooden box with pallet

Delivery: to be loaded by 1 x 20 feet container

- Q: Is it possible to utilize aluminum as a material for manufacturing solar cells?

- <p>Aluminum is not typically used to make solar cells due to its properties. Solar cells are usually made from materials like silicon, which is a semiconductor and can efficiently convert sunlight into electricity. Aluminum, being a good conductor, is used in the manufacturing process of solar cells for its electrical conductivity, but not as the active material that generates electricity. It is used in the form of aluminum paste in the back surface field of solar cells to create a conductive layer and in the frame to provide structural support. However, for the photovoltaic conversion process itself, other materials are more suitable.</p>

- Q: What characteristics distinguish pure aluminum from its alloyed forms?

- <p>Pure aluminum is a soft, lightweight, and highly malleable metal with good electrical and thermal conductivity. It is often used for its corrosion resistance and is relatively inexpensive. Aluminum alloys, on the other hand, are made by combining aluminum with other elements like copper, magnesium, silicon, or zinc to enhance its properties. These alloys are stronger, more durable, and can be tailored for specific applications, such as in aerospace, automotive, or construction. They offer improved strength-to-weight ratios, better resistance to heat and wear, and can be anodized for enhanced surface properties. While pure aluminum is more ductile and easier to weld, aluminum alloys provide greater versatility in terms of mechanical properties and performance.</p>

- Q: Explain the environmental impact of using aluminum in construction materials.

- <p>Aluminum used in building materials has both positive and negative environmental impacts. On the positive side, aluminum is lightweight, durable, and highly recyclable, which reduces waste and conserves resources. It also has good thermal conductivity, which can improve energy efficiency in buildings. However, the production of aluminum is energy-intensive and generates greenhouse gases, contributing to climate change. Additionally, the mining and processing of bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. Despite these issues, the recyclability of aluminum means that its environmental footprint can be significantly reduced through proper recycling practices.</p>

- Q: Is it possible to construct vehicles using aluminum?

- <p>Yes, aluminum can be used to make cars. It is known for its lightweight, high strength, and corrosion resistance, which are desirable properties in automotive manufacturing. Aluminum alloys are commonly used in car bodies, engines, and other components to reduce weight, improve fuel efficiency, and enhance performance. Additionally, its recyclability makes it an environmentally friendly choice for vehicle production.</p>

- Q: Is there any health risk associated with using pure aluminum cookware?

- <p>Using pure aluminum cooking utensils is generally considered safe for most people. However, there are some concerns regarding the potential for aluminum to leach into food, especially at high temperatures or with acidic foods. While the health risks are still a subject of debate, it's recommended to use aluminum cookware with a protective coating or opt for utensils made from other materials like stainless steel or cast iron for long-term health considerations.</p>

- Q: Explain the distinctions between aluminum alloys and pure aluminum in a few sentences.

- <p>Aluminum alloys and pure aluminum differ in composition and properties. Pure aluminum is soft and has low strength, making it less suitable for structural applications. In contrast, aluminum alloys are made by combining aluminum with other elements like copper, magnesium, or silicon to enhance strength, durability, and resistance to corrosion. These alloys maintain the lightweight nature of aluminum while offering improved mechanical properties, making them ideal for various industries, including aerospace, automotive, and construction.</p>

- Q: This question asks about the energy savings achieved by utilizing recycled aluminum compared to producing new aluminum.

- <p>Using recycled aluminum saves a significant amount of energy. It requires only 5% of the energy needed to produce new aluminum from raw materials. This is because recycling aluminum involves melting the metal, which is much less energy-intensive than the mining, refining, and electrolysis processes required for new aluminum production. By recycling aluminum, we can save up to 95% of the energy that would be used in the production of new aluminum.</p>

- Q: What are the various applications of aluminum in the construction industry?

- <p>Aluminum is widely used in construction due to its lightweight, durability, and resistance to corrosion. It is utilized in the manufacturing of window frames, doors, roofing, and facades for its strength and low maintenance requirements. Aluminum is also used in structural components such as beams and columns, and in the construction of bridges and high-rise buildings. Its malleability allows for easy shaping and forming, making it ideal for intricate designs. Additionally, aluminum's thermal conductivity and reflectivity make it suitable for energy-efficient construction.</p>

- Q: Is it possible to recycle aluminum in a landfill setting?

- <p>Aluminum can be recycled, but not in a landfill. Landfills are not designed for recycling; they are for waste disposal. Aluminum recycling typically occurs at specialized facilities where the metal is sorted, cleaned, and processed. Landfills can contaminate aluminum with other materials, making it unsuitable for recycling. Proper recycling of aluminum conserves resources and energy, and it's crucial to recycle aluminum through appropriate channels rather than disposing of it in landfills.</p>

- Q: This question asks for methods to prevent the corrosion of pure aluminum when exposed to environmental factors.

- <p>To prevent corrosion of pure aluminum in the environment, one can apply protective coatings such as paints or anodizing, which forms a dense oxide layer on the surface. Additionally, using aluminum alloys that contain elements like copper, magnesium, and silicon can enhance resistance to corrosion. Regular cleaning and maintenance to remove contaminants that may initiate corrosion are also important. In extreme environments, cathodic protection or the use of inhibitors can be employed to further protect aluminum from corrosion.</p>

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2000 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Mid East; North America; Eur |

| Company Certifications | ISO 14001:2004; FDA |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 30-40 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Air-Conditioner Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 MT m.t.

- Supply Capability:

- 7000MT/MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords