Aluminium Ceiling Panel Thickness - Perforated Panel with Aluminium Ceiling Clip In Type

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

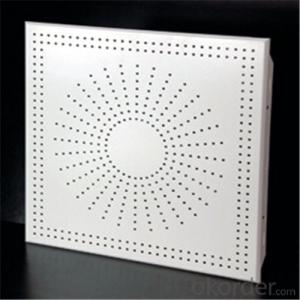

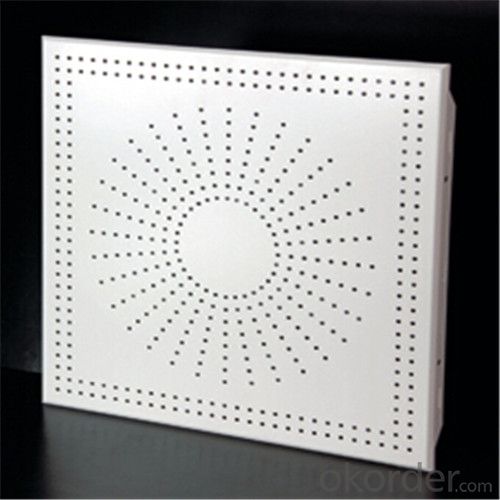

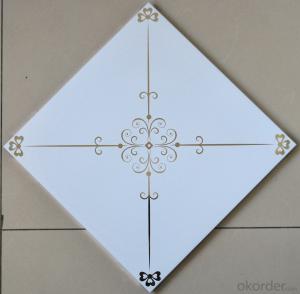

Our square ceiling series include:plan square ceilings,down-level ceilings,combination ceilings,perforated ceilings.

Application

Our aluminum square ceilingcan be widely applied for office,shopping mall,conference room,laboratory and exhibition hall.

Features

1.Rgulated shape

2.Beauty

3.Elegance

4.Widen vision

5.Easy installation

6.Easy cleaning

Square Ceiling series

1.plain square ceiling

2.down-level ceiling

3.combination ceiling

4.perforated ceiling

Base material

Aluminum alloy ,the gread of aluminum alloy can be selected according to the actual requirements.

Type of surface

Surface venner:Power coating(ordinary power,polyester),rolling,laminating,metal anode oxidation treatment.Can be pore panel or punching panel according to the actual requirements.

Size:

595*595mm, 605*605mm

Thickness: 0.5mm,0.6mm,0.7mm

Features:

1.Aluminium material,fireproof,waterproof,soundproof

2.Suspended installation,won't harm the base ceiling

3.Flat non-trace,splicing seamless:

4.Each plate edge have screens orientation to ensure the ceiling smoothly and beautiful.

5.Plates joining together through by keel,which make splicing seamless and engineer cover,and moisture.

6.On the back of the ceiling with the sound-absorbing paper or cotton, make it has the best sound-absorbing function.

7.Suitable for indoor,such as office buildings, schools, hospitals,supermarket, channel, banks, etc.

Specification of aluminum ceiling clip in tiles 600X600

Clip-in | Size | Height | Thickness | Edge |

(mm) | (mm) | (mm) | ||

300*300 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

300*600 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

300*1200 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

400*400 | 1020/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

500*500 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

600*600 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

Lay-in | 275*275 | 8/10 | 0.45-1.0 | Straight Edge |

295*295 | 8/10 | 0.45-1.0 | Straight Edge | |

575*575 | 8/10 | 0.45-1.0 | Straight Edge | |

585*585 | 8/10 | 0.45-1.0 | Straight Edge | |

585*1185 | 8/10 | 0.45-1.0 | Straight Edge |

Description:

1.Superposition joint part between main carrier and vice carrier or vice carrier and carrier is called point lap.

2.It uses lap structure to assembly, connection between joints dovetail very well. The joint face unknits and have a nice appearance.

3.There is a barb at the vice carrier joint, it can avoid loosing and falling from the infection of outside force.

4.Soleplate of main and vice carrier is zincification armor plate, which meets the national GB standard demand. We use baked paint zincifcation armor plate as baked paint panel,whoes capacity of zincification is high. It meet the national GB standard demand.

5. Raw Meterial is galvanized steel with 80-100g/sqm

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: 3DMAX in the aluminum slab ceiling how to do real? (In addition to using the map)

- No map, I really did not do. Do not map to do these things, like no PS do the same background. Even if you have the energy, but the computer can not afford ah

- Q: What is the size of the integrated ceiling plate?

- Home improvement, there are two places to consider the installation of aluminum buckle ceiling, one bathroom, one kitchen, then, the choice of aluminum buckle ceiling will take into account.

- Q: How to distinguish between the aluminum plate is good or bad?

- The corners of the gusset The simplest is to do an experiment, that four pieces of chuck together into a large square to see if the middle of the seam is not very close fit.

- Q: Aluminum cords hanging ceiling, you can turn it?

- Note the problem 5.1 ceiling uneven: the main keel installation when the boom leveling is not serious, resulting in the elevation of the ceiling is inconsistent; construction should be careful operation, check the hanging point of the degree of tightness, and pass the line check the height and flatness is consistent Design requirements and specification standards. 5.2 Light steel skeleton local node structure is unreasonable: ceiling light steel skeleton in the hole, lamp mouth, vents, etc., should be based on the corresponding node on the drawings configuration keel and connectors, so that the structure in line with the requirements of the drawings to ensure hanging The stiffness. 5.3 light steel skeleton hanging is not strong: the ceiling of the light steel skeleton should be hanging in the main structure, and should tighten the boom nut to control the fixed design elevation; roof within the pipeline, equipment parts shall not be hanging on the light steel skeleton. 5.4 cover panel block gap is not straight: cover panel specifications are deviated, the installation is not correct; construction attention to plate specifications, pull the line to find, when installed to ensure the formation of fixed straight. 5.5 pressure section, the pressure side is not tight not straight: the processing material specifications are inconsistent; use should be selected, the operation of the cable line after the fixed, pressure sticky. 5.6 box aluminum alloy ceiling to pay attention to the plate color, to prevent the uneven quality of the ills.

- Q: Thickness: 0.5,0.6,0.7.

- On the same aluminum aluminum plate from the thickness of 0.8 is better than 0.6, but the general project with aluminum slab plate is 0.8 mm, or even thicker, why? Because some of the works with a very long buckle, in order to prevent deformation, so use thicker, hardness of some, on the contrary, home improvement with aluminum slab plate, rarely more than 4 meters, and aluminum buckle on the ceiling no heavy Things, so, home improvement aluminum plate, it can be said that 0.6 mm is enough to use.

- Q: What are the ceilings?

- 1. Gypsum board as a whole ceiling (the whole surface without pattern, easy to crack and deformation). 2. mineral wool board or gypsum board, paint keel ceiling (checkered pattern, easy to deformation). 3. Aluminum plate hanging ceiling (expensive). 4.PVC ceiling (cheap, not durable). 5. New type of steel plate ceiling (price with high, first-class materials, patterns and diverse). 6. Aluminum cubes ceiling (one for shops). 7. Nine finished plate, panel with paint or plastic aluminum (usually used for inter-station walkway)

- Q: What is the depth of the hole in the ceiling to the ceiling?

- In general it is 5 centimeters. Whether it is pulled burst screw or the top of the burst of screws, to be deep enough to be safe.

- Q: Will the aluminum buckle plate integrated ceiling to how much money a square?

- The current integrated ceiling are very cheap, generally also 70 a 200 yuan / square, according to their own budget choice, lighting, Yuba to buy a good, the first Division SAST integrated ceiling, the top ten brands, Wang Jiuchi home city has a shop, in the B area on the 15th, full color

- Q: What is the best thickness of the ceiling?

- Selection process surface treatment is critical When buying, you can determine through the feel of the aluminum plate is smooth and delicate. In addition, the purchase of plastic film board to be more careful, because the coating process requirements, if the artificial directly in the aluminum plate on the film, once the temperature change is too large, easy to fall off the surface.

- Q: How to deal with the aluminum slab board ceiling installation Yuba after the resonance

- If installed after the whole top of the vibration will be in Yuba and keel contact place pad cloth. The main keel is best not to use light steel keel

Send your message to us

Aluminium Ceiling Panel Thickness - Perforated Panel with Aluminium Ceiling Clip In Type

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords