Anodized Aluminum Strips with Structural Aluminum Alloys and Known Isotopes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

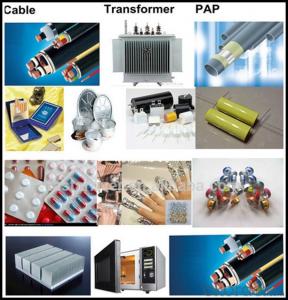

2. Application of Aluminum

(1).Interior: Oil and petrochemical industries...

(2).Exterior: Specialized anti-corrosive applications...

(3).Certain structural retrofit building applications...

3. Feature of Aluminum

In the Earth's crust, aluminium is the most abundant (8.3% by mass) metallic element and the third most abundant of all elements (after oxygen and silicon).The Earth's crust has a higher prevalence of aluminium than the rest of the planet, due to aluminium silicates in the crust. In the Earths mantle, which is only 2% aluminium by mass, these aluminium silicate minerals are largely replaced by silica and magnesium oxides. Overall, the Earth is about 1.4% aluminium by mass (eighth in abundance by mass). In the Earth as a whole, aluminium gains in abundance as compared with the Solar system and Universe, due to Earth's loss of a number of elements which are common in the universe, but which are volatiles at the Earth's distance from the Sun (hydrogen, helium, neon, nitrogen, carbon as hydrocarbon).

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

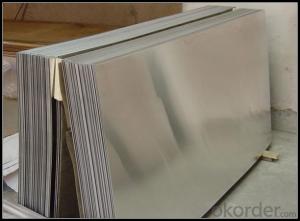

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: The question asks if it's possible to use aluminum strips for insulating the exterior walls of a building.

- <p>Yes, aluminum strips can be used for exterior wall insulation, but they are typically used as a vapor barrier or as part of a metal stud framing system rather than as an insulating material themselves. Aluminum is a good conductor of heat, so it's not an insulator. Instead, it's often used to create a barrier against moisture and air infiltration. For insulation, materials like fiberglass, cellulose, or foam are more appropriate. Aluminum strips can help secure insulation boards in place and provide a base for attaching exterior finishes.</p>

- Q: What are the potential dangers or issues that could arise from using nails or screws to attach aluminum strips?

- <p>There are several risks involved with using nails or screws to install aluminum strips. These include damaging the aluminum strip by causing dents or cracks, especially if the material is thin. There's also the risk of stripping the screw hole, which can weaken the hold and cause the strip to come loose. Additionally, if the aluminum strip is not properly secured, it may lead to accidents or injuries due to falling or improper installation. Using the wrong type of fastener can also lead to corrosion or other material compatibility issues. It's crucial to use the appropriate tools and techniques to minimize these risks.</p>

- Q: Is it possible to utilize aluminum strips in the food packaging industry?

- <p>Yes, aluminum strips are commonly used in food packaging. They are valued for their excellent barrier properties against light, moisture, and gases, which help to preserve the freshness and quality of food. Aluminum's malleability also makes it easy to form into various shapes and sizes for different packaging needs. Additionally, aluminum is recyclable, contributing to sustainability efforts in the food industry.</p>

- Q: What specific tools are required for the installation of aluminum strips on a roof or wall?

- <p>To install aluminum strips on a roof or wall, you generally need a few special tools. These include a measuring tape for precise measurements, a level to ensure the strips are straight, a drill for making holes, and screws or nails for securing the strips. A utility knife may be required for cutting the strips to size, and a pry bar can help with positioning. Safety equipment like gloves and goggles is also essential to protect against sharp edges and debris.</p>

- Q: Is it suitable to use aluminum strips for roofing in areas with high temperatures?

- <p>Yes, aluminum strips can be used for roofing in hot climates. Aluminum is a lightweight, durable, and corrosion-resistant material that can withstand high temperatures without degrading. It reflects heat, reducing the amount of heat absorbed by the roof, which can help keep the interior of a building cooler. Additionally, aluminum's resistance to rust and corrosion makes it an ideal choice for climates with high humidity or where there is a risk of saltwater corrosion. However, it's important to ensure proper installation and ventilation to maximize its performance and longevity.</p>

- Q: This question asks if it's possible to use various types of siding materials on a home's exterior to achieve a desired aesthetic.

- <p>Yes, you can use different types of siding on your home's exterior to match your style. Mixing materials such as vinyl, wood, brick, or stone can create a unique and personalized look. It's important to consider the architectural design and ensure that the materials complement each other in terms of color, texture, and style. Consult with a professional to help you choose the right combination that suits your home and preferences while also considering factors like durability, maintenance, and cost.</p>

- Q: What types of aluminum strips are best suited for specific applications?

- <p>Yes, there are various types of aluminum strips tailored for specific purposes. For instance, 1100 series aluminum strips are known for their high ductility and are often used for deep drawing applications. 3003 series is popular for its corrosion resistance and is commonly used for chemical equipment and food processing. 5052 series offers good formability and is used in marine applications and aircraft structures. 6061 series is strong and often used in structural applications such as truck beds and window frames. Each type has distinct properties that make it suitable for different industries and applications.</p>

- Q: What kind of aluminum strip is most suitable for use in flooring applications?

- <p>The best type of aluminum strip for flooring is typically one that is durable, slip-resistant, and resistant to corrosion. Anodized aluminum strips are often preferred due to their strength, wear resistance, and ability to withstand heavy foot traffic. They also offer a sleek, modern aesthetic and can be used in various flooring applications, including commercial and residential settings. The thickness and width of the strip can vary depending on the specific requirements of the project, but a common choice is a 1mm to 3mm thick strip for stability and support.</p>

- Q: Is it possible to utilize recycled aluminum to fabricate new aluminum strips?

- <p>Yes, recycled aluminum can be used to make new aluminum strips. Recycling aluminum is an efficient process that conserves energy and resources. The recycled aluminum is melted down and then reformed into new shapes, including strips. This process is not only environmentally friendly but also cost-effective, as it requires less energy compared to producing aluminum from raw materials. The recycled aluminum strips maintain the same properties as those made from new aluminum, making them suitable for various applications.</p>

- Q: Describe the steps involved in the manufacturing process of aluminum strips.

- <p>The process for manufacturing aluminum strips involves several key steps. Initially, aluminum ingots are melted in a furnace, often using a direct current furnace for better control over the melting process. The molten aluminum is then poured into molds to create a cast billet. This billet is then heated and passed through a series of rolling mills to reduce its thickness and achieve the desired strip dimensions. During rolling, the aluminum is continuously cooled to control its temperature and maintain its mechanical properties. After rolling, the aluminum strip may undergo additional processes such as annealing to improve ductility or coating to provide a protective layer. Finally, the strip is cut to length, inspected for quality, and packaged for distribution.</p>

Send your message to us

Anodized Aluminum Strips with Structural Aluminum Alloys and Known Isotopes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords