Alloyed flat bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Brand Name: | Model Number: | |||

| Material: | white: |

Packaging & Delivery

| Packaging Detail: | the package of the wire rod steel for construction is standard exporting package |

| Delivery Detail: | 30d upon recipt of L/C |

Specifications

the wire rod steel for construction that we offer have been used in civil construction work for years.

SPECIFICATION

1: WIRE ROD IN COIL

2. STANDARD: AISI,ASTM,BS,DIN,GB,JIS

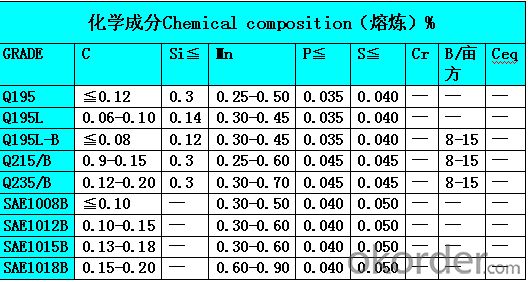

3. STEEL GRAD: Q195--235/SAE1006B/SAE1008B/SA31012B/SDA31015B/SA31018B/SA31022B

4. SIZE: 5--22MM

1) the products that we offer haven been used in civil constrction work for years

2) meet different requirment

3) we can offer accordingly with different demands

- Q: How is the tensile strength of steel wire rod tested?

- The tensile strength of steel wire rod is typically tested using a method called the tensile test or the tension test. This test is performed to determine the maximum load or force that the wire rod can withstand before it breaks or fails under tension. In the tensile test, a representative sample of the steel wire rod is prepared by cutting it into a specific length. The sample is then placed in a testing machine called a tensile testing machine or universal testing machine. This machine consists of two jaws, one stationary and one movable, which grip the ends of the wire rod securely. Once the sample is properly positioned in the testing machine, the movable jaw is pulled away from the stationary jaw, exerting a gradually increasing force on the wire rod. The machine measures the force applied to the sample and simultaneously records the resulting elongation or deformation of the wire rod. During the test, the force and the elongation are continuously monitored until the wire rod fractures. The maximum force applied just before the fracture occurs is recorded as the tensile strength of the steel wire rod. This tensile strength value indicates the maximum load or stress that the wire rod can endure without breaking. To ensure accurate and reliable results, multiple samples are usually tested to account for any variability in the material properties. The average of these results is then taken as the representative tensile strength of the steel wire rod. Overall, the tensile strength of steel wire rod is determined through a controlled testing process using a tensile testing machine, which measures the maximum force applied to the sample before it fractures, providing valuable information about the material's strength and performance.

- Q: What are the different types of coatings for steel wire rod?

- Steel wire rods can be enhanced and safeguarded from corrosion through the application of various coatings. Some commonly employed coatings are as follows: 1. Zinc Coating: Galvanization, also known as zinc coating, is a highly favored option for steel wire rods. It ensures exceptional resistance against corrosion and can be applied using hot-dip galvanization or electroplating techniques. 2. Polymer Coating: Polymer coatings are often utilized to provide extra protection against corrosion and abrasion. These coatings can be applied through dip coating, extrusion, or powder coating methods, offering commendable adhesion and flexibility. 3. Phosphate Coating: Phosphate coatings are commonly employed as a pre-treatment for steel wire rods before the application of other coatings. They enhance the adhesion of subsequent coatings and improve corrosion resistance. 4. Epoxy Coating: Epoxy coatings are renowned for their exceptional adhesion and chemical resistance. They find frequent usage in industrial settings where the wire rods are exposed to harsh environments or corrosive substances. 5. Powder Coating: Powder coatings provide a robust and aesthetically pleasing finish to steel wire rods. These coatings are applied as dry powder and then cured under heat to create a smooth and protective layer. 6. Organic Coating: Organic coatings, such as acrylics or polyurethanes, are often employed for aesthetic purposes or to impart a specific color to the wire rods. These coatings also offer a certain degree of corrosion protection. 7. Ceramic Coating: Ceramic coatings find their application in high-temperature scenarios where the wire rods are subjected to extreme heat or thermal cycling. They exhibit excellent heat resistance and can withstand thermal shocks. It is crucial to select the appropriate coating based on the specific requirements and intended use of the steel wire rods. Different coatings provide varying levels of protection, durability, and resistance to specific environmental factors.

- Q: How is steel wire rod used in the production of fencing and mesh?

- Steel wire rod plays a crucial role in producing fencing and mesh due to its strength, durability, and versatility. These qualities make it an excellent material for creating fences and mesh that can withstand different environmental conditions and provide a high level of security. To manufacture steel wire rod, it goes through hot rolling or cold drawing in the production process. Afterward, the wire rod undergoes further processing to transform it into various forms such as wires, bars, and strands. These forms are then used to create the different components needed for fencing and mesh. When it comes to fencing, steel wire rod is commonly used to create the main structural components like posts and rails. Typically, the wire rod is bent and welded to achieve the desired shape and size. These components are then interconnected and reinforced with additional wires, also made from steel wire rod, to create a sturdy fence structure. Steel wire rod is also utilized in making the mesh or netting of the fence. The wire rod is drawn into thin and flexible wires, which are tightly woven or welded together to form a mesh pattern. This mesh is then attached to the fence posts and rails, providing a secure barrier while allowing visibility and ventilation. Moreover, steel wire rod is employed to create different types of fencing and mesh, including chain-link fences, welded wire mesh, and expanded metal mesh. Each type has its own unique characteristics and applications, but they all rely on the strength and durability of steel wire rod to offer security and protection. In conclusion, incorporating steel wire rod in the production of fencing and mesh ensures that these structures are robust, long-lasting, and capable of enduring harsh conditions. The versatility of steel wire rod allows for the creation of various fence and mesh designs, making it an indispensable material in the construction industry.

- Q: What are the different types of heat treatments used for steel wire rod?

- Steel wire rods undergo various heat treatments to achieve specific properties and benefits. The most commonly used treatments include: 1. Annealing: The steel wire rod is heated to a specific temperature and gradually cooled to enhance its ductility, reduce internal stresses, and refine its microstructure. This improves its workability and mechanical properties. 2. Quenching and tempering: By rapidly cooling the heated steel wire rod, it becomes hardened with increased strength and hardness. Subsequently, tempering involves reheating the quenched steel at a lower temperature to enhance toughness, reduce brittleness, while retaining some of the hardness. 3. Normalizing: Similar to annealing, normalizing involves heating the steel wire rod to a specific temperature and allowing it to cool in still air. This refines the grain structure, improves strength and toughness, and eliminates internal stresses. 4. Stress relieving: Residual stresses accumulated during previous manufacturing processes are reduced through this heat treatment. By heating the rod to a specific temperature and cooling it slowly, stress relieving prevents material distortion or cracking. 5. Case hardening: Also known as carburizing, this treatment increases the hardness and wear resistance of the steel wire rod. Carbon is introduced into the surface layer by heating it in a carbon-rich atmosphere, followed by quenching to achieve the desired hardness. The selection of heat treatment for steel wire rods depends on the desired properties and applications of the final product. Each treatment method offers distinct advantages and is chosen based on the specific requirements of the wire rod.

- Q: What are the advantages of using galvanized steel wire rod?

- There are several advantages of using galvanized steel wire rod. Firstly, galvanized steel wire rod has a high level of corrosion resistance. This is due to the zinc coating that is applied to the surface of the wire rod. The zinc acts as a protective barrier, preventing rust and corrosion from forming on the steel. This makes galvanized steel wire rod suitable for outdoor applications, where it may be exposed to moisture and harsh weather conditions. Secondly, galvanized steel wire rod is incredibly durable. The zinc coating adds an extra layer of protection to the steel, making it more resistant to wear and tear. This means that galvanized steel wire rod can withstand heavy loads and is less likely to break or deform under stress. This durability makes it ideal for use in construction, fencing, and other demanding applications. Another advantage of galvanized steel wire rod is its versatility. It can be easily bent, twisted, and cut to suit various applications. This makes it a popular choice for a wide range of industries, including agriculture, automotive, and manufacturing. Galvanized steel wire rod can be used for making fences, wire mesh, springs, and various other products. Additionally, galvanized steel wire rod is cost-effective. While the initial cost of galvanizing the wire rod may be higher compared to other types of steel, the long-term benefits outweigh the upfront investment. The corrosion resistance and durability of galvanized steel wire rod mean that it requires less maintenance and has a longer lifespan, reducing the need for frequent replacements. Lastly, galvanized steel wire rod is environmentally friendly. The zinc coating used in the galvanizing process is non-toxic and recyclable. This means that galvanized steel wire rod can be easily recycled at the end of its lifespan, reducing waste and minimizing its impact on the environment. In conclusion, the advantages of using galvanized steel wire rod include high corrosion resistance, durability, versatility, cost-effectiveness, and environmental friendliness. These qualities make it a preferred choice for various applications in different industries.

- Q: What are the main factors influencing the choice of steel wire rod production process?

- Several key factors influence the selection of the steel wire rod production process. Firstly, the quality requirements of the final product play a vital role. Each production process has its own capabilities in producing steel wire rods with specific properties such as strength, ductility, and surface finish. The desired characteristics of the wire rod will determine the appropriate production process. Secondly, the cost-effectiveness of the production process is an important consideration. The overall cost of production can be significantly affected by factors like energy consumption, raw material utilization, and labor requirements. It is crucial to evaluate the efficiencies and costs of different processes to make the most economical choice. Moreover, the availability and cost of raw materials also impact the selection of the production process. Steel wire rods can be made from various types of steel, including carbon steel, alloy steel, or stainless steel. The choice of raw material depends on factors such as required mechanical properties, availability, and cost. The production process must be compatible with the chosen raw material. Another factor to consider is the production capacity and scalability of the process. Some processes are more suitable for small-scale production, while others are better suited for large-scale manufacturing. The desired production volume and scalability requirements must be taken into account to ensure the chosen process can meet the production demands. In addition, environmental considerations can also influence the choice of production process. Some processes may generate more waste or emit higher levels of pollutants compared to others. Companies may prioritize sustainable and environmentally friendly production methods, leading them to select a process that minimizes environmental impact. Overall, the selection of the steel wire rod production process is influenced by factors such as desired product quality, cost-effectiveness, availability and cost of raw materials, production capacity and scalability, and environmental considerations. A careful evaluation of these factors is necessary to choose the most suitable production process for a specific application.

- Q: How does the electrical conductivity of steel wire rod vary with different wire drawing processes?

- The electrical conductivity of steel wire rod can vary with different wire drawing processes. Wire drawing is a metalworking process where a wire rod is pulled through a series of dies to reduce its diameter and increase its length. This process can affect the electrical conductivity of the steel wire rod due to several factors. Firstly, the reduction in diameter during the wire drawing process can lead to an increase in electrical conductivity. When the wire rod is drawn through the dies, its cross-sectional area decreases, resulting in a higher concentration of conductive material in a smaller space. This increased concentration of conductive material can enhance the electrical conductivity of the steel wire rod. Secondly, the wire drawing process can influence the microstructure of the steel wire rod, which in turn affects its electrical conductivity. The deformation and strain during wire drawing can cause changes in the crystal structure and grain size of the steel. These changes can have a significant impact on the electrical conductivity of the wire rod. For example, if the wire drawing process leads to grain refinement, it can enhance the electrical conductivity by reducing the scattering of electrons. Additionally, the wire drawing process can also introduce impurities or defects into the steel wire rod, which can affect its electrical conductivity. These impurities or defects can act as scattering centers for electrons, reducing the overall electrical conductivity of the wire rod. Furthermore, the choice of lubricants and cooling methods during the wire drawing process can influence the electrical conductivity of the steel wire rod. Lubricants help reduce friction and heat during the drawing process, which can prevent the formation of oxides or other surface contaminants that could hinder electrical conductivity. Effective cooling methods can also help maintain the desired microstructure and prevent the formation of detrimental phases that could impact electrical conductivity. In conclusion, the electrical conductivity of steel wire rod can vary with different wire drawing processes. Factors such as the reduction in diameter, changes in microstructure, introduction of impurities or defects, and choice of lubricants and cooling methods can all influence the electrical conductivity of the steel wire rod. Careful consideration of these factors during the wire drawing process can help achieve the desired electrical conductivity for specific applications.

- Q: How is steel wire rod used in the manufacturing of wire forms for security fencing?

- Steel wire rod is used in the manufacturing of wire forms for security fencing by being processed through various stages such as drawing, annealing, and coating to obtain the desired strength, flexibility, and corrosion resistance. This rod is then shaped and welded into different wire forms, such as mesh panels or barbed wire, which are essential components of security fencing.

- Q: How are steel wire rods used in the production of screws and bolts for construction?

- Screws and bolts for construction purposes rely heavily on steel wire rods, which serve as the essential ingredient in their production. The process begins with the steel wire rods undergoing a series of manufacturing steps. Initially, the rods are drawn through dies to reduce their diameter and increase their length, a technique known as wire drawing. This step ensures that the wire rods achieve the desired size and strength. Once the wire rods are drawn to the required dimensions, they are then cut into smaller lengths suitable for creating screws and bolts. These shorter lengths are commonly known as blanks or billets. The next stage involves threading these blanks to give them the distinctive shape of a screw or bolt. This threading process is typically executed using specialized machines that cut or roll grooves onto the surface of the wire rods. These grooves provide the necessary grip for the screws and bolts, ensuring a secure connection to the respective materials. After the threading process, the blanks undergo further processing to add various features, such as head shape, drive type, and any additional coatings or finishes required for corrosion resistance. Machining or forging processes are usually employed, depending on the desired specifications of the screws and bolts. Quality control checks are then conducted on the formed screws and bolts to verify that they meet the required standards for strength, dimensions, and overall functionality. Factors such as tensile strength, hardness, and dimensional accuracy are tested to ensure the reliability of the fasteners. The final step involves packaging and distributing the screws and bolts for use in construction projects. These fasteners play a crucial role in connecting different components of a structure, providing stability, strength, and durability to the overall construction. They find widespread use in applications such as framing, securing walls, connecting beams, and joining various building materials. In conclusion, steel wire rods serve as the fundamental raw material for the production of screws and bolts in the construction industry. They undergo a series of manufacturing processes to shape them into fasteners with specific features and properties. These fasteners are essential for the structural integrity and reliability of construction projects, making steel wire rods an indispensable component in the construction field.

- Q: What are the potential applications of stainless steel wire rod?

- Stainless steel wire rod has a wide range of potential applications due to its unique properties and versatility. Some of the potential applications of stainless steel wire rod include: 1. Construction and infrastructure: Stainless steel wire rod is commonly used in construction and infrastructure projects for its strength, durability, and resistance to corrosion. It can be used in the production of reinforcement bars, concrete structures, bridges, and other critical infrastructure components. 2. Automotive industry: Stainless steel wire rod is used in the manufacturing of various automotive components, such as exhaust systems, suspension springs, and engine components. It provides excellent resistance to heat, corrosion, and high temperatures, making it ideal for these demanding applications. 3. Aerospace industry: Stainless steel wire rod finds applications in the aerospace industry due to its lightweight nature and high strength-to-weight ratio. It is used in the production of aircraft components, such as fasteners, cables, and structural elements, where its corrosion resistance and mechanical properties are crucial. 4. Medical equipment: Stainless steel wire rod is widely used in the manufacturing of medical equipment and instruments due to its biocompatibility, corrosion resistance, and ease of sterilization. It is used in the production of surgical tools, implants, orthodontic wires, and other medical devices. 5. Power generation: Stainless steel wire rod is utilized in the power generation industry for its excellent resistance to high temperatures, pressure, and corrosion. It is commonly used in the production of turbine blades, heat exchangers, and other critical components in power plants. 6. Food processing industry: Stainless steel wire rod is extensively used in the food processing industry due to its hygienic properties and resistance to corrosion. It is used in the production of food handling equipment, storage tanks, and processing machinery. 7. Wire products: Stainless steel wire rod is used to produce various wire products, including springs, wire mesh, cables, and fencing. Its high tensile strength, corrosion resistance, and flexibility make it suitable for these applications. 8. Marine industry: Stainless steel wire rod is widely used in the marine industry for its resistance to corrosion in saltwater environments. It is used in the production of marine equipment, boat fittings, rigging, and other components. Overall, the potential applications of stainless steel wire rod are vast and varied, ranging from construction and automotive industries to aerospace, medical, power generation, food processing, wire products, and marine sectors. Its exceptional properties make it a reliable and preferred material for various critical applications where strength, durability, and corrosion resistance are essential.

Send your message to us

Alloyed flat bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords