alloyed wire rod

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

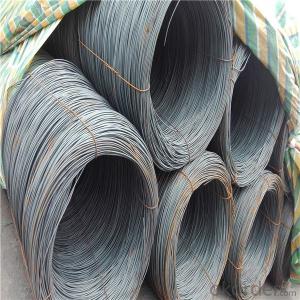

Wire Rod Q235 Details:

| Minimum Order Quantity: | 25 Tons | Unit: | m.t. | Loading Port: | XINGANG PORT,China |

| Supply Ability: | 100,000 Tons Per Month | Payment Terms: | TT or LC |

Product Description:

Specifications of Wire Rod Q235:

Steel Grade: Q235, Standard: GB Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Diameter Tolerance:±0.3mm 6.5mm can be drawing into 2mm/8.0mm can be drawing into 3mm

Brand Name: N-RIVER Place of Origin: Hebei, China Mainland Application: construction, building etc

Chemical Composition:

Please kindly find our chemistry of our material based on Q235 as below for your information

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

| ≤ |

| ≤ | ≤ | |||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

Usage and Applications of Wire Rod Q235:

After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Packaging & Delivery of Wire Rod Q235:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

- Q: What are the different surface defects that can affect the machinability of steel wire rod?

- Some of the different surface defects that can affect the machinability of steel wire rod include cracks, pits, scratches, and scale.

- Q: How is steel wire rod inspected for surface defects?

- Steel wire rod is inspected for surface defects through various methods, including visual inspection, automated optical inspection systems, and magnetic particle inspection. Visual inspection involves trained personnel visually examining the wire rod for any visible defects such as scratches, cracks, or pits. Automated optical inspection systems use advanced cameras and image processing techniques to detect and classify surface defects based on their size, shape, and appearance. Magnetic particle inspection utilizes the magnetic properties of steel to identify surface defects by applying a magnetic field and then examining the rod for any magnetic particles that indicate defects. These inspection methods ensure the quality and integrity of steel wire rods by detecting and addressing any surface defects that may compromise their performance.

- Q: What are the different types of steel wire rod coatings used for improved wear resistance?

- There are several types of steel wire rod coatings used for improved wear resistance. Some of the commonly used coatings include zinc, galvanized, zinc-aluminum, and epoxy coatings. Each of these coatings provides different levels of protection against wear and corrosion, depending on the specific application and requirements.

- Q: What are the transportation options for steel wire rod?

- The transportation options for steel wire rods include trucking, rail, and shipping.

- Q: What are the quality standards for steel wire rod?

- The quality standards for steel wire rod typically include factors such as chemical composition, tensile strength, surface finish, dimensional accuracy, and adherence to specific industry or international standards. These standards ensure that the steel wire rod meets the required specifications for its intended use, whether it is in construction, automotive, or other industries.

- Q: How is steel wire rod used in the production of wire mesh for industrial sieving?

- Steel wire rod is used in the production of wire mesh for industrial sieving as it serves as the primary raw material. The wire rod is first drawn into the desired diameter and then woven or welded to form the wire mesh. This sturdy and durable wire mesh is then used in sieving processes to separate and classify materials based on their particle size, ensuring efficient and accurate industrial sieving operations.

- Q: How is steel wire rod used in the production of wire forms?

- Steel wire rod is used in the production of wire forms as the primary raw material. It is first processed through various machinery to shape and cut the wire into desired forms, such as springs, hooks, or clips. The steel wire rod's strength and durability make it ideal for creating sturdy and reliable wire forms for a wide range of applications in industries like automotive, construction, and manufacturing.

- Q: How is the wear resistance of steel wire rod assessed?

- The wear resistance of steel wire rod is typically assessed through various testing methods, such as the pin-on-disk test or the abrasion test. These tests involve subjecting the wire rod to rubbing or sliding against a specified surface under controlled conditions, measuring the resulting wear or loss of material. The wear resistance is then determined by evaluating the extent of wear or damage to the wire rod.

- Q: How is the mechanical strength of steel wire rod assessed?

- The mechanical strength of steel wire rod can be evaluated using a range of testing methods. One widely used approach involves subjecting a sample of the wire rod to tension until it breaks, known as tensile testing. This test measures the maximum force the wire rod can withstand before failing, also referred to as ultimate tensile strength. Another crucial parameter to consider is yield strength, which indicates the maximum stress the wire rod can tolerate without suffering permanent deformation. Other tests, such as hardness testing, assess the wire rod's surface resistance to scratching or indentation. Popular methods for hardness testing include the Rockwell and Brinell tests. Ductility is another important factor to consider, which measures the wire rod's ability to deform under tensile stress without fracturing. Typically, elongation and reduction of area measurements are used to evaluate ductility. Furthermore, the wire rod's toughness, reflecting its capability to absorb energy prior to fracturing, can be assessed through impact testing. This involves striking the wire rod with a pendulum or falling weight to measure the energy absorbed during fracture. By employing these various testing methods, the mechanical strength of steel wire rod can be thoroughly evaluated, ensuring its suitability for a wide range of applications in industries such as construction, automotive, and manufacturing.

- Q: How is steel wire rod used in the manufacturing of wire mesh fencing?

- Steel wire rod is used in the manufacturing of wire mesh fencing as it serves as the primary raw material. The wire rod is first drawn into the desired thickness and then woven or welded to create the wire mesh. The strong and durable nature of steel wire rod ensures that the resulting wire mesh fencing is capable of withstanding external forces and providing security and containment in various applications.

Send your message to us

alloyed wire rod

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords