Alloyed flat bar-steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Brand Name: | Model Number: | |||

| Material: | white: |

Packaging & Delivery

| Packaging Detail: | the package of the wire rod steel for construction is standard exporting package |

| Delivery Detail: | 30d upon recipt of L/C |

Specifications

the wire rod steel for construction that we offer have been used in civil construction work for years.

SPECIFICATION

1: WIRE ROD IN COIL

2. STANDARD: AISI,ASTM,BS,DIN,GB,JIS

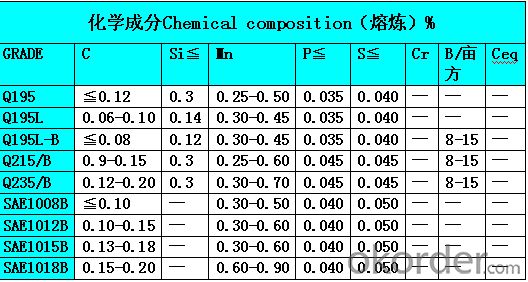

3. STEEL GRAD: Q195--235/SAE1006B/SAE1008B/SA31012B/SDA31015B/SA31018B/SA31022B

4. SIZE: 5--22MM

1) the products that we offer haven been used in civil constrction work for years

2) meet different requirment

3) we can offer accordingly with different demands

- Q: How does the brittleness of steel wire rod vary with different heat treatment processes?

- The brittleness of steel wire rod can vary significantly with different heat treatment processes. Generally, the more rapid the cooling process, the more brittle the steel becomes. For example, quenching, which involves rapidly cooling the steel, can increase its brittleness. On the other hand, processes like annealing, which involves slow cooling, can reduce brittleness and improve the steel's ductility. Therefore, the specific heat treatment process used plays a crucial role in determining the brittleness of steel wire rod.

- Q: What are the factors that affect the mechanical properties of steel wire rod?

- Several factors influence the mechanical properties of steel wire rods. The chemical composition of steel, including the presence of alloying elements like carbon, manganese, silicon, and others, determines its mechanical properties. Strength, toughness, and ductility vary depending on the composition. The microstructure of steel, including grain size and distribution, also affects its mechanical properties. Fine-grained steels generally have higher strength and improved toughness compared to coarser-grained ones. Heat treatment processes can be used to control the microstructure and enhance desired properties. Heat treatment processes like annealing, quenching, and tempering significantly alter the mechanical properties of steel wire rods. They modify the structure and hardness of the material, providing desired levels of strength, hardness, and ductility. Processing conditions during manufacturing can also influence the mechanical properties of steel wire rods. Factors like temperature, cooling rate, and deformation applied during rolling, drawing, or extrusion processes can affect the final properties. Proper control of these parameters is crucial in achieving the desired mechanical properties. The surface condition of steel wire rods can impact their mechanical properties as well. A smooth and clean surface reduces the likelihood of cracks, improves fatigue resistance, and enhances overall performance. Impurities such as sulfur, phosphorus, and non-metallic inclusions can negatively impact the mechanical properties of steel wire rods. Manufacturing defects like cracks, voids, and inhomogeneities can weaken the material and reduce its strength. Environmental factors also play a role in the mechanical properties of steel wire rods. Variables like temperature, humidity, exposure to corrosive substances, and mechanical loading conditions can influence the material's behavior, including its strength, ductility, and corrosion resistance. In conclusion, various factors including composition, microstructure, heat treatment, processing conditions, surface finish, impurities, defects, and environmental factors influence the mechanical properties of steel wire rods. Understanding and controlling these factors are crucial in producing steel wire rods with desired mechanical properties for different applications.

- Q: What are the regulations governing the production and use of steel wire rod?

- The regulations governing the production and use of steel wire rod vary by country and region. However, some common regulations include quality standards, safety requirements, and environmental regulations. These regulations aim to ensure that steel wire rod is produced and used in a safe and environmentally responsible manner, while also meeting the required quality standards.

- Q: What are the different corrosion testing methods for steel wire rod?

- There are several corrosion testing methods available for steel wire rods. These methods help to assess the susceptibility of the wire rods to corrosion and determine their corrosion resistance. Some of the commonly used corrosion testing methods for steel wire rods include: 1. Salt Spray Test: This method involves exposing the steel wire rods to a highly corrosive salt spray environment. The wire rods are placed in a chamber where they are exposed to a continuous salt spray mist. The duration of the test can vary, but it is typically conducted for a specified number of hours or days. The wire rods are then visually inspected for signs of corrosion, such as rust or discoloration. 2. Electrochemical Corrosion Testing: Electrochemical methods, such as the polarization resistance technique, can be used to evaluate the corrosion behavior of steel wire rods. This involves immersing the wire rods in an electrolyte solution and applying a small electrical current to measure the corrosion rate. By analyzing the polarization curves and other electrochemical parameters, the corrosion resistance of the wire rods can be determined. 3. Immersion Test: In this test, the steel wire rods are immersed in a corrosive solution for a specified period. The corrosive solution can vary depending on the intended application or environmental conditions. The wire rods are then removed and inspected for any signs of corrosion, such as pitting or surface degradation. 4. Humidity Test: This method simulates the effects of high humidity on the steel wire rods. The wire rods are placed in a controlled humidity chamber where the relative humidity is maintained at a specified level. The duration of the test can vary, but it is typically conducted for an extended period, ranging from days to weeks. The wire rods are then visually inspected for any signs of corrosion, such as surface oxidation. 5. Cyclic Corrosion Test: This method involves subjecting the steel wire rods to alternating cycles of different corrosive environments. The wire rods are exposed to a sequence of salt spray, humidity, and dry conditions, simulating real-world conditions. This test helps to evaluate the corrosion resistance of the wire rods under changing environmental conditions. 6. Accelerated Corrosion Test: This method involves subjecting the steel wire rods to accelerated corrosion conditions to predict their long-term performance. Various techniques, such as accelerated corrosion chambers or electrochemical methods, can be used to speed up the corrosion process. By analyzing the rate and extent of corrosion, the wire rods' performance in real-world applications can be estimated. These corrosion testing methods provide valuable information about the corrosion resistance of steel wire rods and help in making informed decisions regarding their use in different applications. It is important to select the appropriate testing method based on the specific requirements and environmental conditions that the wire rods will be exposed to.

- Q: How is steel wire rod used in the production of wire ropes for marine applications?

- Steel wire rod is used in the production of wire ropes for marine applications as it serves as the raw material for manufacturing the individual wires that are twisted together to form the rope. The steel wire rod undergoes a series of processes including drawing, heat treatment, and galvanizing to enhance its strength, flexibility, and corrosion resistance. These wire ropes are then utilized in various marine applications such as ship mooring, lifting heavy loads, and securing offshore structures due to their high tensile strength and durability in harsh marine environments.

- Q: How is steel wire rod different from steel bars?

- Steel wire rod and steel bars are both made from steel, but they differ in terms of their shape and size. Steel wire rod is a long, thin, and cylindrical product, typically with a diameter ranging from 5.5mm to 20mm. It is primarily used as a raw material in the manufacturing of various steel products, including nails, wires, and reinforcement materials. On the other hand, steel bars are solid, straight, and usually have a larger diameter compared to wire rods. They are commonly used in construction projects as structural components, such as beams, columns, and reinforcing bars in concrete structures. Therefore, the key distinction lies in their shape and application in different industries.

- Q: How is steel wire rod used in the manufacturing of wire for hairpins?

- Steel wire rod is an essential component in the manufacturing of wire for hairpins. Hairpin wires are typically made from high-quality steel wire rod due to its strength, durability, and flexibility properties. The process begins with steel wire rod being fed into a machine called a wire drawing machine. This machine pulls the steel wire rod through a series of dies of decreasing sizes, gradually reducing the diameter of the wire and shaping it into the desired hairpin wire thickness. The steel wire rod used in hairpin wire manufacturing is carefully selected to ensure it meets specific requirements such as tensile strength, elongation, and surface finish. These properties are crucial to ensure the hairpin wire's ability to withstand the stresses and strains it will encounter during use. The wire rod also undergoes various heat treatments and surface coatings to enhance its strength, corrosion resistance, and aesthetics. Once the hairpin wire is formed, it may undergo additional processes such as straightening, cutting, and bending to achieve the final hairpin shape. These processes help to ensure uniformity in size and shape, as well as smoothness of the wire's surface. The hairpin wire is then typically coated or plated with materials such as nickel, silver, or gold to enhance its appearance and prevent corrosion. Overall, steel wire rod plays a crucial role in the manufacturing of wire for hairpins. Its strength, durability, and flexibility properties, combined with various manufacturing processes, result in high-quality hairpin wires that meet the desired specifications in terms of strength, aesthetics, and longevity.

- Q: How is the price of recycled steel wire rod determined?

- The price of recycled steel wire rod is determined through various factors such as the demand and supply dynamics in the market, the quality and grade of the recycled steel, the costs involved in the recycling process, and the prevailing market conditions. Additionally, factors such as global steel prices, raw material costs, and government policies also influence the price of recycled steel wire rod.

- Q: What are the different types of steel wire rod surface defect monitoring and reporting tools?

- Some of the different types of steel wire rod surface defect monitoring and reporting tools include optical inspection systems, eddy current testing, ultrasonic testing, and magnetic particle inspection. These tools help to identify and report surface defects such as cracks, pits, and surface irregularities in wire rods.

- Q: How is the formability of steel wire rod assessed?

- The formability of steel wire rod is typically assessed through various mechanical tests and evaluations. One of the commonly used methods is the tensile test, where a sample of the wire rod is pulled until it breaks. This test helps determine the maximum load the wire rod can withstand before failure, providing insights into its strength and ductility. Another method used to assess formability is the bend test, where the wire rod is bent to a specified angle without cracks or fractures. This test evaluates the wire rod's ability to withstand deformation without failure or the development of defects. Additionally, the deep drawing test is employed to gauge the wire rod's ability to be stretched and formed into complex shapes without fracturing or tearing. This test is particularly relevant for wire rod used in manufacturing processes such as automotive components or household appliances. Other assessments may include hardness testing, which measures the wire rod's resistance to indentation or penetration, and impact testing, which evaluates its ability to absorb energy under sudden loading conditions. By conducting these tests and evaluations, manufacturers and researchers can determine the formability of steel wire rod and ensure it meets the required standards and specifications for specific applications.

Send your message to us

Alloyed flat bar-steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords