Alkali Resistant Glass Wool Fiber Roving for Refractory Fireplace Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

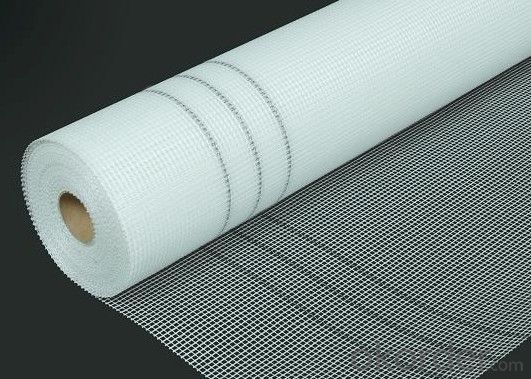

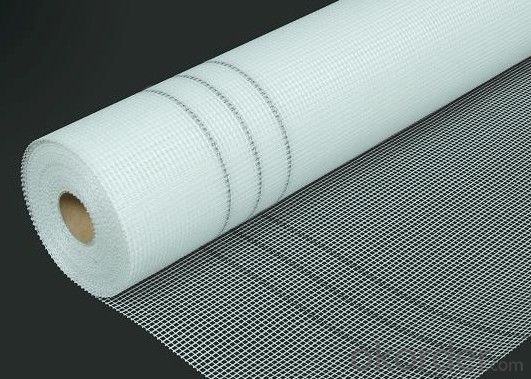

| Place of Origin: | China (Mainland) | Brand Name: | glass fiber cloth | Model Number: | Glass fiber Woven Roving |

| Application: | Wall/Roof covering Cloth | Weight: | 430g-2500g/sqm | Surface Treatment: | Silicon Coated |

| Width: | 30mm-20000mm, 30mm-20000mm | Weave Type: | Plain Woven | Yarn Type: | E-Glass |

| Alkali Content: | Alkali Free | Standing Temperature: | 550 | Color: | white |

| woven style: | plain woven | Glass type: | E-Glass | temperature: | 550 |

| Surface treatment: | silicon coated | Length: | 100-200m | fiberglass Woven Fabric *: | fiberglass Woven Fabric * |

| Brand: | glass fiber cloth

| unit mass: | 400g/600/800g |

Packaging & Delivery

| Packaging Details: | container |

| Delivery Detail: | 10days upon the buyers' payment |

Specifications

Glass fiber Woven Roving for automoblie parts

1.wide applications

2.High quality with best price

3.width can be demand

Products Features and Advantages

1.Well-distributed, even tensile strength, good vertical performance.

2.Fast impregnation, good moulding property, easily removing air bubbles.

3.High mechanical strength, less strength loss in wet condition.

- Q: Are there any differences between glass wool and rock wool in terms of appearance, I can't distinguish them, why?

- They are completely different products, and put it in a simple way, glass wool is made of glass, rock wool is made of stone,

- Q: Standard for the implementation of glass wool products

- GB / T 13350-2000 "Glass wool and its products for insulation" and GB / T 17795-1999 "Glass wool for building insulation"

- Q: How to conduct thermal insulation construction of external wall glass wool?

- I would like to give a brief introduction to the usage of glass wool as the thermal insulation for equipment. 1, Cleaning dust on the surface of equipment. 2, Using adhesive to glue the iron sheet of insulation nails (iron sheet of one square centimeter will be fed in the middle with a slightly harder iron wire of about 8 centimeters) on the surface of the device. Distribution density depends on the weight of glass wool. If insulated cotton is 1 m * 0.5 m, it merely needs to glue seven to eight insulation nails. When glue of iron sheet finished, the device is like a hedgehog. 3. Once insulation nails sticked firmly, it needs to affix to glass wool, fixing it with a piece of spare iron sheet with a hole in the middle of it (it is round and is a set with insulation nails), and then bend the redundant part of iron wire. Wish it will help you. Thank you!

- Q: What environmental pollutions will be created during the production of glass wool?

- There are harmful health hazards in the exhaust gas during the production of glass wool, such as phenol, formaldehyde, and glass fiber dust. Glass wool is very small. If it is on the skin, it will be atingle and itchy. If it gets into lungs, it will be quite dangerous.

- Q: What's the types of glass wool points? do they have the same sound insulation effect?

- Mineral wool and rock wool basically

- Q: How can I fix the glass cotton insulation board to the wall?

- The method to fix the thermal insulation partitions to the wall: 1: metal components are buried in the wall, set separators (movable method), or side drilling in thick plates and embed them in wall(movable method, IKEA separators use the same method), or carpenter fixes and decorates in accordance with components(they can not be removed once fixed). They are strong and stable. This method is suitable for new masonry walls. 2: Drill wall and insert rebar to the wall, set separators (movable method), or side drilling in thick plates and embed them in wall(movable method, IKEA separators use the same method), or carpenter fixes and decorates in accordance with components(they can not be removed once fixed). This method is suitable for most of wall with separators on it. 3: Use expaned anchor bolts on the wall to fix slotted-angle shelvings, set separators (movable method), or carpenter fixes and decorates in accordance with components(they can not be removed once fixed). The disadvantage of this method is that slotted-angle shelvings are ugly, but books and other objects can be put there to cover the diagonal bracings. The advantage of it is good bearing capacity, is suitable for heavy items and decorations. 4: Buy finished products of iron bracket or special mounting bracket, cantilever bracket(commonly used in stores), drill walls and use plastic bolts or fix with wooden chocks and screws. Glass partitions can be used, the cost is slightly higher, beautiful, carrying capacity is not too high, strong variability (upper and lower adjustable baffle spacing). Glass partitions can be used, though they are a little bit expensive, and have relatively lower bearing capacity, they are beautiful and have strong variability(the interval between the upper and lower partitions can be changed).

- Q: How to convert thickness if the heat insulation effects of glass wool board and rubber and plastic board is the same?

- It can be converted according to the experience The two products can be compared with each other the contrast is relatively poor (depending on use) five six thick glass wool use 2 rubber and plastic board Pay attention to the problem of usage and the environment

- Q: what's the temperature the high temperature glass wool endure?

- 400 degrees

- Q: What is the uses of aluminum foil glass wool felt?

- Roll glass wool felt is coiled materials for large area coverage. It is not only thermal-insulating, but also can reduce shock and absorb sound,especially the medium and low frequency noise. It can help reduce the noise and improve the working environment. This material can be tailored based on the actual needs, mainly used for architectural indoor, muffler systems, transportation, refrigeration equipment, damping, sound absorption, noise reduction for the household appliances. Glass wool felt overlaid with aluminum foil has strong thermal radiation resistance. It is good lining material for high temperature workshops, control room, inner walls of machine room,compartment and flat top.

- Q: What are the standards of glass wool board?

- The thickness of glass wool board are 0.7 mm and 0.5m m, and it will soon enter the thinner (eg 0.4mm) thickness process. Basically, a TFT- LCD panel needs two glass substrates, they are used for bottom glass substrate and the base plate of color filter. Generally, the supply proportion of liquid crystal plate assembling factory and processing factory of the color filter glass substrate by glass substrate manufacturing suppliers is about 1:1.1 to 1:1.3.

Send your message to us

Alkali Resistant Glass Wool Fiber Roving for Refractory Fireplace Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords