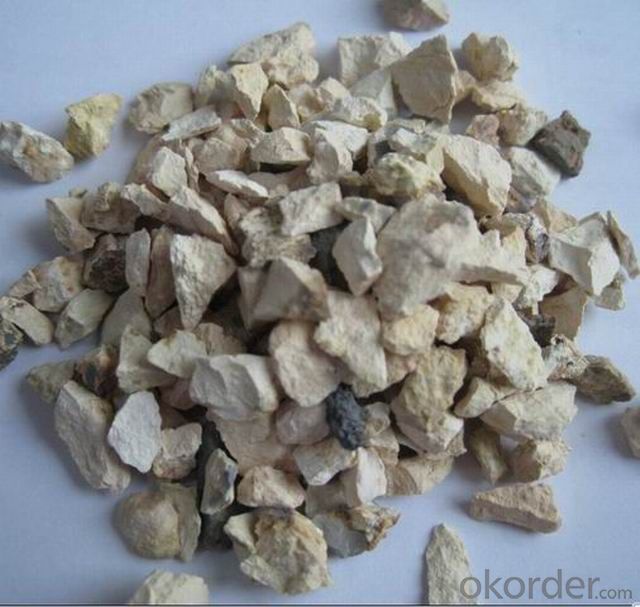

88% Calcined Bauxite - Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Mingyue Bauxite and Calcined Bauxite:

Mingyue Bauxite, ie. bauxite ore, whose main content is Aluminium oxide with, who is department of hydrated

alumina containing impurities in appearance of earthy mineral;

Mingyue Calcined Bauxite is burnt bauxite, who is used for producing the existing uneven materin in nature --

alumina and aluminium. The purpose of calcining bauxite is to remove crystal water and improve the content of alumina.

Mingyue Bauxite Secification:

Al2O3 | Fe2O3 | TiO2 | K2O+Na2O | CaO+MgO | Bulk density |

≥65 | ≤2.5 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.6 |

≥75 | ≤2.5 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.7 |

≥80 | ≤2.5 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.8 |

≥85 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.0 |

≥86 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.1 |

≥87 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.2 |

≥88 | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

Mingyue Refractory Bauxite Level:

Level | Chemical Composition (%) | Refractoriness (℃) | Bulk Density (g/cm3) | ||

Al2O3 | CaO | Fe2O3 | |||

superfine | >85 | <0.6 | <1.4.0 | >1790 | >3.6 |

first grade | >80 | <0.6 | <3.0 | >1790 | >3.0 |

second grade+1 | 70~80 | <0.8 | <3.0 | >1790 | >2.8 |

sencond grade | 60~70 | <0.8 | <3.0 | >1770 | >2.65 |

third grade | 50~60 | <0.8 | <2.5 | >1770 | >2.55 |

Product Uses

Mingyue Bauxite and Calcined Bauxite:

1. Aluminum industry;

2. Precision casting;

3. Refractory industry;

4. Silica acid aluminum firefibre;

5. Mixed with magnesium oxide, it can be an nice bonding agent, especially for pouring entire steel teeming ladle lining;

6. Manufacture bauxite cement, grinding abrasives;

7. Ceramic industry, and chemical industry for making aluminium compounds.

- Q: What is the fire resistance thickness of the thin fire-retardant coatings?

- Our thin steelwork fireproof coatings: the fire resistance is 2.5 hours, the thickness is 4.9 mm, the fire resistance is 2.0 hours, the thickness is 3.5 mm, the fire resistance is 1.5 hours, the thickness is 1.75 mm, the fire resistance is 1.0 hours, the thickness is 1.17 mm.

- Q: which kind of fire?bulkhead is better?

- I think fire bulkhead is good, fire bulkhead also known as non-combustible fire retardance board, and it's made by various incombustible?material after the scientific pressing, and has good flame resisting properties, it's non-combustible time can reach over 3 hours, high mechanical strength,it has characteristics of non-explosive, water and oil resistance, good chemical corrosion resistance and non-toxic.

- Q: what's the varieties of fire-proof?sealing?material?

- ATD-AB, organic fire-proof caulking, fire retardant bag, fire retardant net, fire retardant ring, fire barrier wrap, fireproofing sealing strip, flexibility fireproofing coiled material, fireproof glue, etc., fireproofing sealing materials currently on the market can be divided into two types, one is the traditional type: flexible organic caulking, WXY-II, fire retardant bag, fire?bulkhead, cable refractory coating; there are some new materials used in large-scale projects: fireproofing coating board system (fireproofing coating board, intumescent fireproof sealing tape, elastic fireproof sealant, Waterborne Fire-retardant Coating), fire retardant module system (fire retardant module, sealing gum, cable refractory coating), fireproofing plaster system (fireproofing plaster, sealing gum, cable refractory coating).

- Q: which kind of refractory is used in golden smelting furnace? How about his using temperature

- generally the price of the quartz sand refractory material is higher and the temperature can meet the requirement of 2000 degree.

- Q: What are the insulation fireproofing materials?

- Insulated shoes, insulated gloves, tape (cloth, plastic, as well as waterproof) yellow wax tube, mouth care, fireproof (ie asbestos cloth is sold by jin) there is pressure-caps black tape, waterproof tape ,casing. There are glass fiber needle felt is widely used in electrical, chemical, construction, transportation, automotive and other industries interlayer insulation and silencer system, and used as an insulating fireproof material.

- Q: Does anyone know which materials belong to light fire resistant material?

- Fire partitions can be divided into organic and inorganic fire partitions, the main ingredient of organic fire partitions is organic material, which can be used for cable tray with corrosion-resistant and fire protection requirements, and the main ingredient of inorganic fire partitions is inorganic material, mainly used for fire protection. As the main component is inorganic material, it can not be use in projects with acid-resistant and alkali-resistant requirements. Of course, the price of the same amount of organic fire partitions is generally more expensive than that of the inorganic fire partitions . The fire endurance of these two products of general enterprises are 3 hours.

- Q: What's the classification of refractory material?

- Magnesium aluminum is complex and mainly seeing what classification standard is like according to the appearance shape can be divided into two categories, setting and not setting according to the acid alkali can be divided into acidic, magnesia, high aluminum, ramming expected, spinel, spray coating, plastic, just the quality of the jade, daub material according to the chemical composition is divided into, such as clay, neutral and alkaline according to the operation mode can be divided into different castable, magnesium, calcium, magnesium chrome

- Q: What is the magnesium carbon refractory?

- The composition of refractory brick There are many types of raw materials of refractory brick, mainly divided into six categories: Soil, stone, sand, mineral, power and others. The first kind of raw material, soil: Aluminum soil, kaolin, clay, diatomaceous earth The second kind of raw material, Stone: Fluorite, kyanite, andalusite, forsterite, vermiculite, mullite, pyrophyllite, chlorite, dolomite, sillimanite, magnesia-alumina spinel, silica The third kind of raw material, sand: Pottery, zircon sand, quartz sand, magnesite The fourth kind of raw material, ore: Chrome ore The fifth kind of raw material, powder: Aluminum powder, silica powder, silicon powder The sixth kind of raw material of refractory brick, others: Asphalt, graphite, phenolic resins, perlite, cenosphere, sialon, corundum, silicon sulfate, silicon carbide, sodium silicate, silica solution, boron carbide, calcium aluminate cement, nitride material, shale ceramisite, alumina, alumina sol and zirconia, etc.

- Q: What are the materials of class A fire resistant window?

- Environmentally friendily, non-poisoned non-peculiar smell, non-radioactive; non-combustible, fireproof, moisture-proof, corrosion-resistant; easy to operate, lightweight, high strength, themal insulation, sound insulation; able to be cut, planed, sawed and carved. It also meets GB8624 -2006A1 level non-combustible standards. Lightweight, high strength, anti-aging, corrosion resistance; meeting the GB / T20285-2006 Opium (AQ1) safety and environmentally friendly products; Foamed fire door core board specifications: 2100 × 900 × (26 ~ 65) mm; 2050 × 850 × (26-65), and many other specifications. I hope my answer can help you.

- Q: Who knows about the B-level fireproof insulation materials?

- Commonly used B-level materials: Molding polystyrene foam, extruded polystyrene board, gelatine powder polyphenyl granule heat insulating slurry. Although the polyurethane is not the commonly used material, but the 9mm composite of monolayer gypsum board and PU insulating material can reach B-level.

Send your message to us

88% Calcined Bauxite - Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords