Al-Zinc coated steel coil for Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

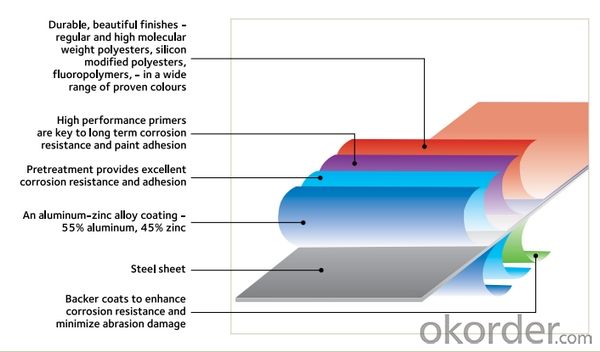

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

The detailed information for the Al-Zinc coated steel coil is as following and it is mainly using for roofing producing, making ceiling grid and all kinds of roll forming structure.

Thickness: 0.20mm to 1.20mm

Width: 914mm, 1000mm, 1200mm, 1219mm and 1250mm, or slit narrow strip according to customer request, can be slit from 20mm to 610mm.

Coil ID: 508mm

Coil weight: 3 tons to 6 tons

Thickness tolerance: +/- 0.02mm or according to customer request.

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 25 tons | 25 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of steel coil loading and unloading devices?

- There are several types of steel coil loading and unloading devices, including coil carriages, coil lifters, coil turners, coil grabs, and coil tilters. These devices are designed to safely and efficiently handle steel coils during the loading and unloading process, ensuring smooth operations in various industries such as manufacturing, construction, and transportation.

- Q: How are steel coils used in various industries?

- Steel coils are used in various industries for their durability and versatility. They are commonly used in automotive, construction, and manufacturing industries for making structures, machinery, and appliances. Steel coils are also utilized in the energy sector for producing power generation equipment and in the transportation industry for making ships and railcars. Overall, steel coils play a significant role in providing strength and reliability in a wide range of industrial applications.

- Q: How are steel coils processed for edge conditioning or slitting?

- Steel coils are processed for edge conditioning or slitting through a series of steps. First, the coils are inspected for any defects or irregularities. Then, the coils are uncoiled and leveled to ensure a flat surface. After that, the edges are trimmed or conditioned to remove any imperfections. Finally, the coils are slit into narrower strips according to the desired width.

- Q: How are steel coils inspected for flatness variations?

- Steel coils are inspected for flatness variations using various methods such as visual inspection, measurement techniques, and automated systems. Visual inspection involves trained personnel visually inspecting the coil's surface for any irregularities or deviations from flatness. Measurement techniques involve using precision instruments such as straight edges, feeler gauges, or laser sensors to measure the flatness at different points along the coil's length. Automated systems use advanced technologies like laser scanning or optical sensors to quickly and accurately detect any flatness variations in the steel coils. These inspections help ensure that the coils meet the required flatness specifications and quality standards.

- Q: who, when and where was dual phase steel invented?

- Dual Phase steels refers to a distinct group of alloys which are used for automotive bodies. These were developed to give improved deep drawing (for shaping) and strength while on the road. Most of the work was started at the same time in the 1970s as a response to the oil crisis (history repeats!) with SSAB in Europe, US Steel and British Steel leading the way. There are many variants of the dual phase alloys prefered by each of the auto manufacturers. The work on these steels led the way for TRIP (transformation induced plasticity) steels, rephosphorised steels and HSLA (high strength low alloy) steels. There is a distinction between these steels and duplex steels which typically refer to austenitic/ferrtic stainless steels. Also be aware that everyday low carbon steels with 0.1%-0.6% carbon will have a ferritic/pearlitic structure but are not considered to be dual phase So to summarise: Who - major steel companies worldwide When - from about 1973 onwards (up to around 1977 when the developments went in other directions) Where - Europe, USA and Japan (but I'm not sure who it was in Japan doing the work)

- Q: How are steel coils tested for compliance with industry standards?

- To ensure compliance with industry standards, steel coils undergo a series of rigorous quality control measures. These tests are conducted to verify that the coils meet necessary specifications and are suitable for various applications. Among the primary tests performed on steel coils is dimensional inspection. This entails measuring the thickness, width, and length of the coils to ensure they fall within specified tolerances. Any deviations from the required dimensions may indicate manufacturing defects or potential issues during fabrication. Another crucial test is visual inspection, where trained inspectors meticulously examine the coils for surface defects like scratches, dents, or cracks. Identifying and rectifying these defects is essential as they can impact the performance and durability of the steel coils before they are supplied to customers. Additionally, mechanical properties testing is carried out to assess the strength, elasticity, and toughness of the steel coils. This includes conducting tests for tensile strength, yield strength, and elongation measurements. These evaluations help determine if the coils are suitable for specific applications and if they meet the required performance standards. Furthermore, chemical composition analysis is performed to validate the elemental composition of the steel coils. This analysis is crucial as it ensures that the steel meets the required chemical requirements, including the presence of specific alloying elements. Deviations in composition can significantly affect the overall quality and performance of the coils. Corrosion resistance testing is also of great importance, particularly for coils used in environments with high humidity or exposure to corrosive substances. Coils are subjected to simulated real-world conditions, such as salt spray or humidity chambers, to evaluate their resistance to corrosion. Lastly, various non-destructive testing techniques, including ultrasonic testing and magnetic particle inspection, are employed to detect internal defects or discontinuities in the steel coils. These tests assist in identifying any hidden flaws that could compromise the structural integrity of the coils. In summary, steel coils undergo a comprehensive array of tests to ensure adherence to industry standards. By conducting these tests, manufacturers can guarantee that the coils meet the required specifications, thereby providing customers with high-quality products tailored to their specific needs.

- Q: How are steel coils used in the production of roofing panels?

- To manufacture roofing panels, steel coils are indispensable. These coils, usually composed of galvanized or coated steel, serve as the fundamental material for producing robust and top-notch roofing panels. Initially, the steel coils undergo a sequence of operations in a production facility. These operations involve flattening, cleaning, and shaping the coils to achieve the desired dimensions and profiles for the roofing panels. This process guarantees that the steel coils possess uniform thickness and are devoid of any impurities or flaws that could compromise the final product's integrity. Once the steel coils are prepared, they are fed into a roll forming machine. In this machine, the coils are gradually bent and shaped into the specific design and size required for the roofing panels. The roll forming process imparts the panels with their distinct corrugated or standing seam profiles, which enhance their strength and ability to withstand various weather conditions. After the roll forming process, the steel coils are divided into individual roofing panels of the desired length. These panels then undergo further processing to incorporate additional features, such as coatings or finishes, to enhance protection against corrosion and improve aesthetic appeal. Protective layers, such as zinc or paint, are often applied to the steel coils to enhance their resistance to rust, UV rays, and other environmental factors. Lastly, the roofing panels are packaged and transported to construction sites or distributors for installation. The utilization of steel coils in the production of roofing panels ensures that the final product is sturdy, long-lasting, and capable of withstanding heavy loads, strong winds, and other external forces. Steel is renowned for its high tensile strength, making it an ideal material for creating durable roofing panels. In conclusion, steel coils play a vital role in the production of roofing panels. Through a series of manufacturing processes, they are transformed into the desired dimensions and profiles, ensuring consistency and quality. The resulting roofing panels are not only visually pleasing but also highly resilient, providing superior protection and longevity for buildings.

- Q: Having a new kitchen and would like to know the pros and cons of stainless steel as opposed to white appliances. I can only think of finger marks on the SS, which I believe are difficult to remove. Anyone had both that they could advise please?

- Like others said about Stainless Steel, plus if bleach accidentally touched it, it will leave a permanent scar, Stainless Steel can be cleaned with water and soap then with baby oil. White will be better.

- Q: How are steel coils used in the production of lighting fixtures?

- Steel coils are an essential component in the production of lighting fixtures. These coils are typically made of high-quality steel, which provides durability and strength to the final product. In the manufacturing process, the steel coils are first uncoiled and then passed through a series of machines. These machines cut and shape the steel into various parts and components required for lighting fixtures. The steel is often bent, stamped, or rolled to create the desired shapes and sizes. These parts may include the base, frame, arms, or other structural elements of the lighting fixture. Once the steel components are formed, they are then further processed and finished. This may involve welding, polishing, or coating the steel to enhance its appearance and protect it from corrosion. After the steel parts are finalized, they are assembled with other components like electrical wiring, bulbs, shades, and switches to create the complete lighting fixture. The use of steel coils in lighting fixture production ensures that the finished products are sturdy, long-lasting, and able to withstand various environmental conditions. Steel's strength allows for the creation of intricate designs and shapes, enabling manufacturers to produce lighting fixtures that are not only functional but also aesthetically pleasing. Overall, steel coils play a crucial role in the production of lighting fixtures by providing the necessary strength, durability, and versatility required for these products.

- Q: 1943 steel pennies

- You really don't want to do anything to to them. If they're rusty, that's just the way they are now. Store them in a dry place. Cleaning will do more damage than good, and will hurt the value. If it were possible to undo the damage, our cars would never rust, iron pipes wouldn't pit, and everything would be made of steel. Don't let it worry you, they're still worth having.

Send your message to us

Al-Zinc coated steel coil for Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords