AISI 4340 Forged Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AISI 4340 Forged Steel Round Bars

Technical Paramenters

Chemical Composition | Mechanical Properties (In Quenched & Tempered State) | ||

C | 0.38-0.43 % | Tensile strength(MPA) | ≥980(100) |

Si | 0.15-0.35 % | Yield strength (MPA) | ≥835(85) |

Mn | 0.60-0.80 % | Elongation (δ5/%) | ≥12 |

Cr | 0.70-0.90 % | Reduction in Area (ψ/%) | ≥55 |

Ni | 1.65-2.00 % | Impact (J) | ≥ 78 |

P | ≤0.035 % | Impact toughness value αkv (J/cm2) | ≥98(10) |

S | ≤0.040 % | Hardness | ≤269HB |

Mo | 0.20-0.30 % | ||

Standard | ASTM A29/A 29M-05 | ||||||||||

Grade | 4340 | ||||||||||

MOQ | 1 Metric Ton | ||||||||||

Diameter | 8mm~1500mm | ||||||||||

Length | 6m,12m or as required. | ||||||||||

Diameter Tolerance | As required | ||||||||||

Condition of delivery | Hot rolled,Cold Rolled or as required. | ||||||||||

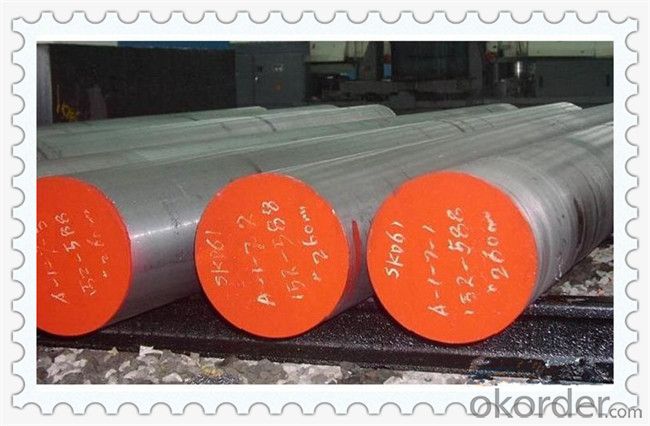

Products Show

Product Overviews

Steel wire, Steel Round bar

Diameter: 0.14mm-2000mm

Steel Square bar

Size : 50mm * 50mm-600mm *600mm

Steel Plate(sheet), flat steel bar

Thickness: 0.1mm-800mm Width: 10mm to 1900mm

Cold-rolled Plate(sheet)

Thickness: 0.1-8mm Width: 1000mm

Hot-rolled Plate(sheet)

Thickness: 6-200mm Width : 210-1900mm

Surface: 2B, BA, 6K, 8K, 12K, etc.

Welded/seamless Steel Pipe(tube)

outer diameter: 6-219mm wall thickness: 1-35 mm.

Length:according to the customer's requirements.

Condition of delivery

Hot-rolling+annealing,normalizing+tempering,quenching+tempering,cold-drawn or according to the customer's requirements.

Surface:rough machining,fine machining,polishing,bright,pickling,black or according to the customers’ requirements.

Furnaces for metallurgical processing electrode arc + LF,VD,VOD,ESR,Vacuum consumable electrode.

Ultrasonic inspection 100% ultrasonic inspection for any in perfections or according to the customers’ requirements.

All of our steels can be customized(standard GB, ASTM, JIS, DIN, etc.)

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: Are steel round bars available in custom sizes?

- Yes, steel round bars are available in custom sizes. Steel round bars can be manufactured to meet specific size requirements and specifications. Custom sizes can be requested based on the diameter, length, and overall dimensions of the round bar. Whether it is for a specific project or application, many steel manufacturers and suppliers offer the option to customize the size of round bars to suit individual needs.

- Q: What are the advantages of using sulfur-alloy steel round bars?

- There are several advantages of using sulfur-alloy steel round bars. Firstly, sulfur-alloy steel round bars offer improved machinability, making it easier to shape and cut the material into desired forms. Additionally, the sulfur content in the alloy enhances the overall strength and hardness of the steel, making it more durable and resistant to wear and tear. Moreover, sulfur-alloy steel round bars have excellent thermal conductivity, allowing for efficient heat transfer during various applications. Lastly, these bars are cost-effective as they offer a combination of desirable properties at a relatively lower price compared to other specialized alloys.

- Q: What is the difference between a hot-rolled and a cold-drawn steel round bar?

- The manufacturing process and resulting properties distinguish a hot-rolled steel round bar from a cold-drawn one. To produce hot-rolled bars, a billet or ingot is heated to a high temperature, typically around 1100 to 1300 degrees Celsius, and then rolled into the desired shape and size. This process yields a rougher surface finish and larger tolerances compared to cold-drawn bars. Hot-rolled bars exhibit less precision in dimensions and may contain surface defects such as scale or rust. In contrast, cold-drawn bars undergo manufacturing by pulling a hot-rolled bar through a die at room temperature. This process reduces the diameter and enhances the surface finish, resulting in a smoother and more precise product. Cold-drawing also improves the mechanical properties of the steel, including increased strength, hardness, and improved surface quality. The cold-drawing process provides closer dimensional tolerances, making cold-drawn bars suitable for applications that demand higher precision. In conclusion, the distinction between hot-rolled and cold-drawn steel round bars lies in the manufacturing process, resulting in differences in surface finish, dimensional tolerances, and mechanical properties. Hot-rolled bars are produced at high temperatures, possess a rougher surface, and have larger tolerances. On the other hand, cold-drawn bars are manufactured at room temperature, exhibit a smoother surface, closer dimensional tolerances, and enhanced mechanical properties. The choice between the two depends on specific application requirements and the desired characteristics of the final product.

- Q: What are the different surface coatings available for steel round bars?

- There are several different surface coatings available for steel round bars, each with their own unique benefits and applications. Some of the most common surface coatings include: 1. Galvanized Coating: This involves applying a layer of zinc to the surface of the steel round bar through a process called hot-dip galvanizing. The zinc coating provides excellent corrosion resistance, protecting the steel from rust and other forms of degradation. Galvanized coatings are commonly used in outdoor and high-humidity environments. 2. Epoxy Coating: Epoxy coatings are applied as a powder or liquid and then cured through a chemical reaction. They offer excellent chemical resistance, durability, and protection against corrosion. Epoxy coatings are often used in industrial and marine applications where harsh chemicals or saltwater exposure are a concern. 3. Chrome Plating: This involves electroplating a layer of chromium onto the surface of the steel round bar. Chrome plating offers high corrosion resistance, as well as excellent hardness and wear resistance. It is commonly used in applications where aesthetic appeal and enhanced durability are desired, such as automotive parts and decorative fixtures. 4. Powder Coating: Powder coating is a dry finishing process that involves applying a powdered polymer to the surface of the steel round bar and then heat-curing it. This creates a durable and decorative finish that is resistant to chipping, scratching, and fading. Powder coatings are available in a wide range of colors and textures, making them popular for architectural and decorative purposes. 5. Black Oxide Coating: Black oxide is a conversion coating that is created by a chemical reaction with the steel surface. It provides a black, decorative finish while also offering mild corrosion resistance. Black oxide coatings are commonly used in applications where an aesthetic appearance is desired, such as firearms and hardware. These are just a few examples of the different surface coatings available for steel round bars. The choice of coating will depend on the specific requirements of the application, including the desired level of corrosion resistance, durability, and aesthetic appeal.

- Q: What is the maximum elongation of steel round bars?

- The maximum elongation of steel round bars may vary based on the particular grade and composition of the steel. Nonetheless, typically, the maximum elongation for steel round bars hovers around 20-30% of their original length. Consequently, these bars can stretch or elongate by up to 20-30% before reaching their breaking point or ultimate tensile strength. It is worth mentioning that this maximum elongation is influenced by several factors, including steel quality, manufacturing process, and any heat treatment employed on the bars. Therefore, it is advisable to refer to the manufacturer's specific specifications and consider the intended application of the steel round bars in order to establish the maximum elongation for a specific case.

- Q: What are the different types of heat treatments applied to steel round bars?

- There are several types of heat treatments applied to steel round bars, including annealing, normalizing, quenching, tempering, and case hardening. These treatments are used to improve the physical and mechanical properties of the steel, such as increasing its hardness, strength, toughness, and ductility, depending on the desired application and requirements.

- Q: Can steel round bars be used for making hydraulic systems?

- No, steel round bars are not suitable for making hydraulic systems as they lack the necessary properties like corrosion resistance and flexibility required for hydraulic applications.

- Q: Can steel round bars be used in the production of tools?

- Certainly, the utilization of steel round bars in tool production is highly feasible. The exceptional strength, durability, and versatility of steel render it extensively employed in the manufacturing of tools. Specifically, steel round bars are frequently employed due to their capacity to undergo machining, forging, and heat treatment, thereby transforming into diverse tool components like cutting edges, shafts, handles, and dies. The elevated tensile strength, wear resistance, and corrosion resistance of steel round bars render them an ideal choice for tool production, guaranteeing both longevity and performance. Moreover, steel can be effortlessly tailored and molded to meet the specific requirements of various tools, establishing it as the preferred material within the industry.

- Q: How are steel round bars used in the manufacturing of agricultural machinery?

- Steel round bars are commonly used in the manufacturing of agricultural machinery as they provide strength, durability, and flexibility. These bars are often used to construct various components such as axles, shafts, and pins, which play a crucial role in supporting and transmitting power within the machinery. The high tensile strength of steel round bars allows them to handle heavy loads and withstand harsh operating conditions, ensuring the reliability and longevity of the agricultural equipment.

- Q: Will the theoretical weight of thread steel and round steel be the same?

- The theoretical weight of threaded steel and round steel is the same. The middle part of the steel bar size ratio is small, the design time actually unit weight are the same, just screw steel crescent and transverse ribs prominent, resulting in heavy steel should be better than the illusion of formula is 0.00617 multiplied by the square of the diameter / m.

Send your message to us

AISI 4340 Forged Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords