aisi 316L stainless steel sheet with PVC coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

aisi 316L stainless steel sheet with PVC coating!!!

1.hot rolled and cold rolled stainless steel sheet detailed information:

Type | stainless steel sheet |

Thinckness | 0.3mm-60mm |

Widthness | 50mm~2000mm |

Length | 1000mm~1500mm or as request |

Brand name | TISCO,JISCO,BAOSTEEL,POSCO etc. |

Standard | JIS, AISI, ASTM, GB, DIN, EN |

Material | 201,202,304,304L,316,316L,317,310S,309S,410,420,430,904L etc |

Surface | 2B,BA,HL,BK,NO.1,NO.4,etc |

Certificate | We accept the third inspections |

Application | Bridge, Shipbuilding,roofing,Car, Construction,Chemical,etc |

Payment | T/T, 30% deposit, blance before loading, L/C |

Note | We can produce other standard as the customers’ require |

2. 200 series stainless steel sheet Applications :

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments,Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware,architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasivesThe most popular finishes | Milk & Food processing acilities, Hospital Equipment, Bath-tub |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

Stainless steel maintenance:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Packing

Bundles, seaworthy wooden pallets or wooden cases.With or without edge protector, steel hoop and seals, in 20' or 40' container or as per customers' requirements.

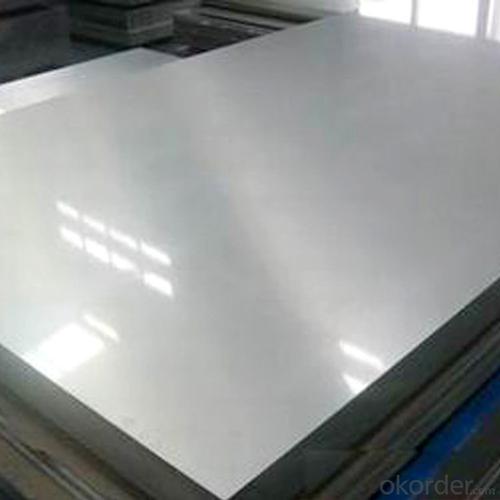

Product display

PVC Coated

Why do you choose us?

1) Our products are high quality and best price.

2)We have experience in this line for many years.

3)We have professional team and the factory.

4)It's very important for a company to be honest in the process of trading and so do we.

- Q: Stainless steel pipe welding interface leakage, how can we not leak?

- Protection gas flow, current and voltage should be chosen according to process;

- Q: Can stainless steel pipes be used for firefighting systems?

- Yes, stainless steel pipes can be used for firefighting systems. Stainless steel is a durable and corrosion-resistant material, making it suitable for such applications where durability and resistance to heat and pressure are required.

- Q: Can stainless steel pipes be used in food processing industries?

- Yes, stainless steel pipes can be used in food processing industries. Stainless steel is a highly durable and corrosion-resistant material that does not react with food or beverages, making it ideal for use in food processing facilities. It is also easy to clean and maintain, ensuring the safety and hygiene of the food processing process.

- Q: How do stainless steel pipes compare to carbon fiber pipes?

- Stainless steel pipes and carbon fiber pipes have their own unique characteristics and are used in different applications. Stainless steel pipes are known for their durability and strength. They are highly resistant to corrosion and can withstand high temperatures and pressures. This makes them suitable for various industries such as oil and gas, chemical, and construction. Stainless steel pipes have a longer lifespan and can handle heavy loads, making them a reliable choice for many applications. However, stainless steel pipes are relatively heavy and may require additional support structures. On the other hand, carbon fiber pipes are lightweight and have a high strength-to-weight ratio. They are made from carbon fibers embedded in a resin matrix, resulting in a strong and rigid material. Carbon fiber pipes are commonly used in industries such as aerospace, automotive, and sports equipment. The lightweight nature of carbon fiber pipes allows for increased fuel efficiency in vehicles and improved performance in sports equipment. However, carbon fiber pipes are more expensive than stainless steel pipes and may not be as resistant to extreme temperatures or corrosive environments. In summary, stainless steel pipes are known for their durability and resistance to corrosion, making them suitable for heavy-duty applications. Carbon fiber pipes, on the other hand, are lightweight and offer high strength-to-weight ratio, making them ideal for applications where weight reduction is critical. The choice between stainless steel and carbon fiber pipes ultimately depends on the specific requirements of the application and the trade-offs between cost, weight, and performance.

- Q: Can stainless steel pipes be used for chemical laboratories?

- Indeed, chemical laboratories can utilize stainless steel pipes. Due to its exceptional resistance to corrosion and ability to withstand diverse chemicals and temperatures, stainless steel emerges as an optimal substance for managing and conveying various chemicals within a laboratory context. In addition, stainless steel pipes deliver remarkable durability, strength, and dependability, rendering them appropriate for both customary and specialized laboratory purposes. Moreover, these pipes are effortlessly cleaned and maintained, thereby guaranteeing a hygienic and secure laboratory environment.

- Q: Can stainless steel pipes be used for underground water supply lines?

- Indeed, underground water supply lines can utilize stainless steel pipes. Due to its exceptional resistance to corrosion, stainless steel proves to be an excellent option for subterranean applications where the pipes may encounter soil, moisture, and other corrosive elements. Moreover, its impressive strength and durability characteristics guarantee that the pipes can endure the pressure and strain associated with burial. Additionally, stainless steel serves as a hygienic material that does not release any hazardous substances into the water supply, rendering it safe for drinking purposes. In conclusion, stainless steel pipes present themselves as a dependable and enduring choice for underground water supply lines.

- Q: Can stainless steel pipes be cold worked?

- Indeed, cold working is a viable option for stainless steel pipes. By subjecting the metal to deformation at normal temperatures, without any heating prerequisites, the desired outcomes can be achieved. Given the malleable and adaptable nature of stainless steel, shaping and sizing through cold working can be effortlessly accomplished. Techniques like bending, flaring, swaging, and drawing can be effectively employed to meet precise specifications when it comes to stainless steel pipes. Moreover, cold working not only augments the steel's robustness and rigidity but also renders it suitable for diverse applications in sectors such as construction, automotive, and manufacturing.

- Q: Can stainless steel pipes be used for power generation?

- Power generation can utilize stainless steel pipes, as they are a versatile and durable material commonly employed in various industries, including power generation. Their attributes, such as excellent corrosion resistance, high strength, and heat resistance, make them suitable for applications involving high temperatures and pressures. Within power generation, stainless steel pipes find frequent use in constructing power plants, including fossil fuel-fired, nuclear, and renewable energy facilities. These pipes transport different fluids, such as steam, water, and fuel, throughout the power generation system. The benefits of stainless steel pipes in power generation stem from their capacity to withstand extreme conditions, including high temperatures and corrosive environments. By resisting corrosion, they preserve the pipes' integrity and longevity, ensuring reliable and uninterrupted operation of power generation systems. Moreover, stainless steel pipes exhibit a high resistance to thermal expansion and contraction, which proves invaluable in power generation applications with frequent temperature fluctuations. This characteristic prevents leaks and maintains the overall efficiency of the power generation process. In conclusion, due to their corrosion resistance, high strength, and ability to endure extreme conditions, stainless steel pipes are extensively employed in power generation. They play a vital role in fluid transportation within power plants and contribute significantly to the overall efficiency and reliability of power generation systems.

- Q: How can I clean the stainless steel tube?

- Grease can be applied to soft cloth to dissolve alcohol. It is important to rinse off the alcohol and dry it so that it has a shiny metal.

- Q: Can stainless steel pipes be used for irrigation well systems?

- Yes, stainless steel pipes can be used for irrigation well systems. Stainless steel is highly resistant to corrosion and can withstand various environmental conditions, making it a suitable choice for irrigation applications. Additionally, stainless steel pipes offer long-term durability and maintain the quality of water being transported, ensuring efficient irrigation system performance.

Send your message to us

aisi 316L stainless steel sheet with PVC coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords