Acrylic Coated Fiberglass Fabric - High Quality Warp Knitting Fiberglass Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

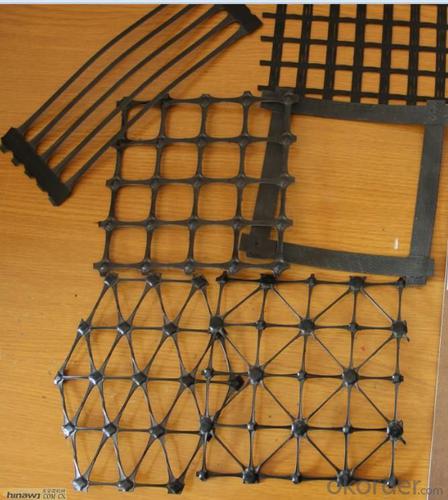

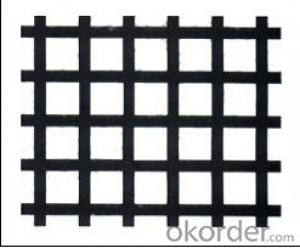

Warp Knitting fiberglass geogrid

The Warp Knitting Fiberglass geogrid selects the excel in synthetic fiber as a raw material,uses the warp knitting oriented structure,latitude and longitude in the fabric to the yarn between not curving condition.

2.Characteristics

Each kind of higher Uygur path,railroad’s soft roadbed enhancement isolation different base earth material.

2. The river bank,the slope of embankment strengthen stably.

3. Each kind of ground strengthens stably.

4. Strengthens the bridge connection surface.

Product Features

1. Geogrid width ranging from 1000mm to 6000mm

2. High intensity, high module, low slow change ,anti-aging , anti-embrittlement, tensile strength to be high strength.

3.Application

Product No. | Stretching ratio(%) | Grid(mm) | Width(mm) | ||

Vertical | Horizontal | ||||

PET20-20 | 13 | 20 | 20 | 12.7x12.7 25.4x25.4 | ±5 |

PET30-30 | 13 | 30 | 30 | 12.7x12.7 25.4x25.4 | ±5 |

PET40-40 | 13 | 40 | 40 | 12.7x12.7 25.4x25.4 | ±5 |

PET50-50 | 13 | 50 | 50 | 12.7x12.7 25.4x25.4 | ±5 |

PET80-80 | 13 | 80 | 80 | 12.7x12.7 25.4x25.4 | ±5 |

PET100-100 | 13 | 100 | 100 | 12.7x12.7 25.4x25.4 | ±5 |

PET120-120 | 13 | 120 | 120 | 12.7x12.7 25.4x25.4 | ±5 |

5.FAQ

Note: The Warp Knitting Polyestergeogrid are available with a width range of 1000mm~6000mm.Other specifications are also available on customer request.

- Q: Can fiberglass fabrics be used for reinforcement in architectural structures?

- Indeed, architectural structures can benefit from the use of fiberglass fabrics for reinforcement. Fiberglass, known for its strength and lightweight nature, possesses exceptional resistance to corrosion and high tensile strength, rendering it an ideal choice for reinforcing various architectural elements. The construction industry often employs fiberglass to strengthen concrete structures like walls, beams, and columns. By embedding fiberglass fabrics into concrete, its durability and strength increase, offering additional support and minimizing the risk of cracks or structural failure. Moreover, fiberglass fabrics display flexibility, allowing easy molding and shaping to accommodate diverse architectural designs and structures. Ultimately, fiberglass fabrics prove to be a versatile and dependable option for reinforcing architectural structures.

- Q: What are the safety precautions when working with fiberglass fabric?

- When working with fiberglass fabric, it is important to take certain safety precautions to protect yourself from potential hazards. Here are some key safety measures to consider: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, including goggles or safety glasses, a respirator or mask, gloves, and protective clothing. This will help minimize the risk of inhaling fiberglass particles, getting them in your eyes, or having direct skin contact. 2. Ventilation: Ensure that the work area is well-ventilated to prevent the accumulation of fiberglass dust or fumes. If working indoors, use exhaust fans or open windows to promote airflow and remove any airborne particles. 3. Dust Control: Minimize the generation of fiberglass dust by using wet methods, such as wetting the fabric before cutting or using a water mist to control airborne particles. Consider using a dust collection system or vacuum with a HEPA filter to capture any fiberglass dust that may be produced. 4. Cutting and Handling: When cutting fiberglass fabric, use appropriate tools such as shears or a rotary cutter to avoid fraying. Handle the fabric carefully to prevent the release of loose fibers into the air. If possible, use pre-cut fiberglass pieces to minimize the need for cutting on-site. 5. Cleanup: After completing the work, clean up any fiberglass dust or debris using a vacuum cleaner with a HEPA filter. Avoid using compressed air or brooms, as they can disperse the particles into the air. Dispose of any waste material in accordance with local regulations. 6. Hygiene: Practice good personal hygiene by washing your hands and face thoroughly after working with fiberglass fabric. Launder any contaminated clothing separately to avoid cross-contamination. 7. Training: Ensure that all individuals working with fiberglass fabric are properly trained on the potential hazards, safety procedures, and the correct use of PPE. Regularly review and update safety protocols to promote a safe working environment. By following these safety precautions, you can minimize the risks associated with working with fiberglass fabric and protect your health and well-being.

- Q: Can fiberglass fabric be used for filters?

- Yes, fiberglass fabric can be used for filters. It is commonly used in applications such as air filters, oil filters, and water filtration systems due to its high efficiency in trapping particles and its resistance to chemicals and heat.

- Q: Rural cement flat roof room, how to do waterproof, anti leakage best?

- The surface of the base is cleaned up, the water content is not more than 9%, the formation is dense, and the joints of each node are tidy and complete, and meet the requirements.

- Q: Are fiberglass fabrics suitable for use in the defense industry?

- Yes, fiberglass fabrics are suitable for use in the defense industry. Fiberglass fabrics are known for their excellent strength-to-weight ratio, which makes them ideal for applications that require lightweight but durable materials. In the defense industry, where equipment and structures need to withstand extreme conditions and protect individuals and assets, fiberglass fabrics have proven to be highly effective. One of the key advantages of fiberglass fabrics is their resistance to heat, fire, and chemicals. This property makes them suitable for various defense applications, including the construction of ballistic protection panels, armor systems, and protective clothing for military personnel. Fiberglass fabrics can also be used in the production of fuel tanks, radomes, and military vehicle components due to their ability to withstand intense heat and harsh chemicals. Furthermore, fiberglass fabrics have good electrical insulation properties, which are crucial in the defense industry. They can be used for manufacturing electrical insulation materials, such as insulating tapes and sleeves, for wiring and cables in military vehicles, aircraft, and ships. This ensures the safety and reliability of electrical systems, even in demanding environments. In addition to their excellent mechanical and thermal properties, fiberglass fabrics are cost-effective and readily available in the market. This makes them an attractive choice for defense industry manufacturers, as they can meet the stringent requirements of military-grade applications while keeping production costs under control. Overall, the unique characteristics of fiberglass fabrics, including their strength, resistance to heat and chemicals, electrical insulation properties, and cost-effectiveness, make them highly suitable for use in the defense industry. Their versatility and reliability make them a preferred choice for various defense applications, contributing to the safety and effectiveness of military operations.

- Q: Can fiberglass fabric be used for making automotive parts?

- Automotive parts can indeed be made using fiberglass fabric. Renowned for its robustness, longevity, and ability to withstand high temperatures and chemicals, fiberglass fabric proves to be an excellent choice for automotive purposes. It facilitates the creation of diverse automotive components like hoods, fenders, spoilers, and interior elements such as door panels. The flexibility of fiberglass fabric enables the production of bespoke automotive parts with intricate designs. Furthermore, its lightweight nature aids in enhancing fuel efficiency and overall vehicle performance.

- Q: Can fiberglass fabric be used for seals?

- Indeed, seals can indeed be made using fiberglass fabric. With their remarkable thermal, chemical, and electrical resistance properties, fiberglass fabrics prove to be highly suitable for a plethora of sealing applications. These fabrics are capable of producing gaskets, seals, and insulation materials that cater to diverse industries such as automotive, aerospace, marine, and electrical. The impressive strength and flexibility of fiberglass fabric enable it to easily mold to uneven surfaces, guaranteeing a trustworthy and long-lasting seal. Moreover, the moisture, oil, and chemical resistance of fiberglass fabric ensures the seals' effectiveness and durability.

- Q: Are fiberglass fabrics suitable for use in the construction industry?

- Indeed, fiberglass fabrics prove to be a fitting option for utilization within the construction sector. These fabrics are crafted from delicate glass fibers, which are interwoven to produce a resilient, long-lasting, and adaptable material. This renders them a commendable selection for diverse construction undertakings. The construction industry finds fiberglass fabrics suitable primarily due to their elevated strength-to-weight ratio. They exhibit exceptional tensile strength and possess the ability to withstand substantial burdens and strains. As a result, they are well-suited for reinforcing concrete, providing structural reinforcement, and fortifying various construction components such as walls, beams, and columns. Moreover, fiberglass fabrics showcase resistance against corrosion, chemicals, and moisture. This attribute makes them apt for usage in environments that commonly encounter exposure to these factors, including coastal regions or industrial settings. Furthermore, fiberglass fabrics possess non-combustible properties and exhibit remarkable fire resistance, which is pivotal in ensuring the safety of a structure. Another advantageous characteristic of fiberglass fabrics is their versatility. They boast the ability to be effortlessly molded and shaped into a plethora of forms, rendering them suitable for an extensive array of construction applications. They can be employed to fabricate architectural embellishments, such as decorative panels or facades, as well as for insulation, roofing, and waterproofing systems. Furthermore, fiberglass fabrics are renowned for their exceptional thermal and sound insulation properties. Consequently, they prove highly desirable for enhancing energy efficiency and reducing noise propagation within buildings. They contribute towards maintaining comfortable indoor temperatures, diminishing heating and cooling expenses, and cultivating a tranquil and pleasant living or working atmosphere. To conclude, fiberglass fabrics are exceedingly well-suited for implementation within the construction industry. Their strength, durability, resistance to various elements, versatility, and insulation properties establish them as an exceptional choice for a wide array of construction applications. They contribute significantly towards the overall quality, safety, and energy efficiency of buildings.

- Q: Is fiberglass fabric resistant to high temperatures?

- Yes, fiberglass fabric is generally resistant to high temperatures. This is due to the nature of the material itself, as fiberglass is made from woven strands of glass fibers. These fibers have a high melting point, typically above 1000 degrees Fahrenheit (538 degrees Celsius), which allows the fabric to withstand high temperatures without burning or disintegrating. Fiberglass fabric is commonly used in applications where heat resistance is required, such as insulation, fire blankets, and protective clothing. However, it is important to note that the specific temperature resistance of fiberglass fabric can vary depending on the manufacturing process and any additional coatings or treatments applied to the fabric. Therefore, it is always recommended to check the product specifications or consult with the manufacturer to ensure that the fiberglass fabric is suitable for the desired temperature range.

- Q: What is fiberglass sound absorption board?

- Glass wool is the molten glass fibrosis, the formation of cotton like material, chemical composition of glass, is a kind of inorganic fibers. With good forming, small volume density, thermal conductivity, both thermal insulation, sound-absorbing performance, corrosion resistance, chemical stability.

Send your message to us

Acrylic Coated Fiberglass Fabric - High Quality Warp Knitting Fiberglass Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords