Acm Aluminum Coil - Red Color Coating Aluminum Coil with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Red Color Coating Aluminum Coil with High Quality

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Red Color Coating Aluminum Coil with High Quality

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Red Color Coating Aluminum Coil with High Quality

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

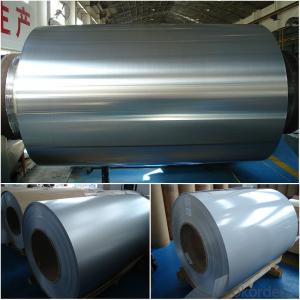

5. Image of Red Color Coating Aluminum Coil with High Quality

6. Package and shipping of Red Color Coating Aluminum Coil with High Quality

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How are aluminum coils used in the production of cookware?

- Aluminum coils play a crucial role in the production of cookware due to their unique properties and versatility. These coils are used as the primary material in the manufacturing process of various types of cookware, including pots, pans, and baking sheets. Firstly, aluminum coils are known for their excellent heat conductivity, which allows for efficient and even heat distribution throughout the cookware. This property ensures that food is cooked evenly and reduces the chances of hot spots or uneven cooking. This is particularly important for achieving optimal cooking results and preventing food from burning or sticking to the cookware. Secondly, aluminum coils are lightweight yet durable, making them ideal for cookware production. The lightweight nature of aluminum ensures that the cookware is easy to handle and maneuver while cooking, reducing the risk of accidents or injuries. Additionally, aluminum's durability ensures that the cookware can withstand high temperatures, constant use, and the rigors of everyday cooking without warping or deforming. Furthermore, aluminum coils are highly resistant to corrosion and rust, making them suitable for cookware that comes into contact with food and liquids. This property ensures that the cookware remains hygienic and safe for cooking purposes, as aluminum does not react with acidic or alkaline ingredients commonly used in cooking. Moreover, aluminum coils are malleable and can be shaped into various cookware designs, including pots, pans, and bakeware with different sizes, shapes, and depths. This flexibility allows for the production of cookware that caters to different cooking techniques and preferences. In terms of production, aluminum coils are typically subjected to a series of manufacturing processes, such as rolling, annealing, and stamping, to transform them into the desired cookware shape. These processes ensure the final cookware product meets the required specifications in terms of thickness, strength, and appearance. In conclusion, aluminum coils are essential in the production of cookware due to their excellent heat conductivity, lightweight yet durable nature, resistance to corrosion, and malleability. These properties enable the creation of high-quality cookware that provides efficient and even cooking results, durability, and ease of use. Overall, aluminum coils contribute significantly to the functionality and performance of cookware, making them a popular choice in the industry.

- Q: We are shopping for a new LQ trailer. We are looking at several different brands and noticed that some have aluminum skin on an aluminum frame, and others have aluminum skin on a steel frame. Other than the obvious differences in weight and cost, what are other benefits/disadvantages of each? Thanks

- Steel is heavier, which makes the frame sturdier, but having gone from a 1973 Shoop two horse steel bumper pull to a 2008 Wrangler Aspen aluminum three horse slant w/ tack room, the new trailer, at 16', is so much lighter than the old, even with three horses in it. There is a definite savings in gasoline! Our truck never changed. We are still pulling with our 1999 Dodge Ram Lariat 1500 4x4. But we did have a brake box installed in truck! The trailer was manufactured with a brake/fuse box electric brakes.

- Q: This question asks about the suitability of aluminum coils for outdoor applications based on their weight and strength.

- <p>Yes, aluminum coils are lightweight and strong, making them suitable for outdoor use. Aluminum is known for its high strength-to-weight ratio, which means it can withstand significant stress without adding much weight. It also has excellent corrosion resistance, which is crucial for outdoor applications where exposure to weather elements can lead to degradation. Additionally, aluminum's malleability allows it to be easily shaped and formed into various configurations for different outdoor structures and applications. Its light weight also reduces the load on structures, which can be an advantage in many construction scenarios.</p>

- Q: my homework was to find out how do you get aluminium for rocks! I've been looking around but every web site i've been on only says that aluminium comes from rocks, but it doesn't say how you get it from rocks.e.g you get wool from sheep by shearing of their coat.so if anyone knows how you get aluminum from rocks please tell me i need your help.

- Aluminum is derived from a rock called Bauxite, which consists of a mixture of up to three aluminum minerals. Bascally they mine it, smelt it (heat to very high temperatures) and you get aluminum. You'll probably get a better answer form someone who is more familiar with the process, but that's a very rough idea.

- Q: How do aluminum coils perform under low-temperature applications?

- Aluminum coils generally perform well under low-temperature applications due to the metal's high thermal conductivity and excellent resistance to low temperatures. This allows the coils to efficiently transfer and distribute heat, making them suitable for various cooling and refrigeration systems. Additionally, aluminum's natural corrosion resistance helps maintain the coils' performance and durability in low-temperature environments.

- Q: Can a rolling machine be utilized to transform aluminum coils into flat sheets?

- <p>Yes, you can use a rolling machine to roll aluminum coils into sheets. Rolling machines are specifically designed to apply pressure and reduce the thickness of metal coils, such as aluminum, into thinner, flatter sheets. The process involves passing the aluminum coil through the rolling mill, where it is compressed between rollers. This process can be repeated to achieve the desired thickness and flatness of the aluminum sheet. It's important to ensure the rolling machine is suitable for aluminum and that the appropriate settings are used to avoid damaging the material or the machine.</p>

- Q: What rules or laws govern the transportation of old or damaged aluminum coils?

- <p>Yes, there are regulations on the transportation of old or damaged aluminum coils. These regulations often fall under hazardous materials or waste transportation laws, depending on the condition of the coils. In the United States, the Department of Transportation (DOT) regulates the transportation of hazardous materials, which may include damaged aluminum coils if they pose a risk. The Environmental Protection Agency (EPA) also has guidelines for the transportation of waste materials. Internationally, the International Maritime Dangerous Goods (IMDG) Code and International Air Transport Association (IATA) Dangerous Goods Regulations provide guidance for the safe transport of such materials. Compliance with packaging, labeling, documentation, and handling requirements is crucial to ensure safety and avoid penalties.</p>

- Q: Can aluminum coils be used in signage applications?

- Indeed, signage applications can make use of aluminum coils. The durability, corrosion resistance, and lightweight characteristics of aluminum render it a favored material for signage purposes. Aluminum can effortlessly take on different shapes and sizes, making it suitable for a wide range of signage types, including outdoor signs, billboards, trade show displays, and more. Furthermore, aluminum coils boast exceptional weather resistance, guaranteeing the preservation of the signage's integrity and vibrancy even in harsh environmental circumstances. The versatility and longevity of aluminum establish it as the preferred option for signage applications across diverse industries.

- Q: How are aluminum coils manufactured to specific dimensions?

- Aluminum coils are manufactured to specific dimensions through a process known as rolling. In this process, large aluminum ingots are heated and then passed through a series of rolling mills, where they are gradually reduced in thickness and elongated. By adjusting the speed and pressure of the rolling mills, manufacturers can control the dimensions of the aluminum coils, ensuring they meet the required specifications.

- Q: How are aluminum coils used in the production of battery enclosures?

- Aluminum coils are used in the production of battery enclosures as they provide a lightweight and durable material that can be easily molded and shaped to form the enclosure. The coils are typically processed and formed into specific shapes using a combination of heating, rolling, and cutting techniques. This allows for the creation of seamless and tightly sealed enclosures that can protect the batteries from external elements and provide efficient heat dissipation.

Send your message to us

Acm Aluminum Coil - Red Color Coating Aluminum Coil with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords