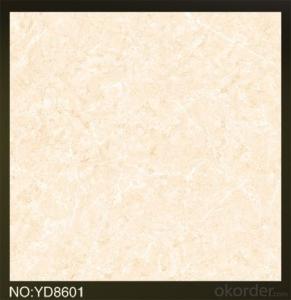

Acid and Heat-resistant Bricks with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Tons watt

- Supply Capability:

- 100000 Tons per Year watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main technical indexes:

Item |

Unit |

Value |

Standard |

Volume density |

G/m3 |

2.21-2.24 |

HG/T3210-1986 |

Apparent porosity |

% |

9.3-10.5 |

HG/T3210-1986 |

Water adsorption |

% |

4.2-4.7 |

GB/T8488-2001 |

Cold/heat shock resistance |

950-20°C |

not crack after 10 times |

GB/T8488-2001 |

Elastic constant |

Mpa |

2138 |

DIN |

Compressive strength |

Mpa |

100 |

JC424-91 |

Thermal conductivity |

W/m.k |

1.175 |

DIN |

Expansion coefficient of thermal film |

1/°C |

3.2×10-2 |

DIN |

Thermal expansion rate |

% |

0.31 |

DIN |

Acid resistance |

% |

≥99.7 |

GB/T8488-2001 |

Remark:

1. Acid/heat resistant tile, plate, tube was checked and accepted pursuant to QB/SNC00-9.

2. Acid/heat resistant tile, plate, tube can be manufactured in accord with the specification, size or blueprints offered by clients and design departments.

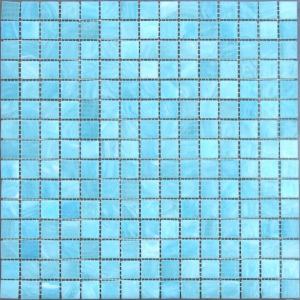

- Q: I want 12x12 tiles on the floor of the bathroom. But on the countertop (small, less than 6sqt) should I do large tiles, or smaller tiles of a similar style? And for the backsplash, should it be the same as the counter or the floor? Not so good with the design aspect. :)

- All your tile selections should co-ordinate but do not need to match exactly. I like the big tiles on the floor but not on the counters and back splash. The large tile will make those areas seem out of scale. I'd go with a similar tile but in a smaller size on the counter and back splash and see if you can find some accent tile to work into your design of the back splash. All it takes is a band of something like natural stone, glass tile or a textured tile to kick it up a notch and by using the more expensive tile sparingly, you're not increasing your costs but certainly increasing the eye appeal.

- Q: I am looking for an obsolete 8X8 ceramic tile I believe was made by Interceramic. It‘s described on my original sales slip from 1999 as IC WestPalm Surf It‘s solid white in color and has a slight pebble texture. I need to modify my kitchen some and don‘t want to tear up the entire floor to install new type tile. Any ideas how to find this tile if there‘s any left out there.

- I agree with Fred on this one! But I do want to offer some help, try adding a border to the existing tile by chipping some of the edge pieces out and adding a complimentary tile in the same size but a nice color maybe set at a diagonal. Hope this helps!

- Q: Have very cheap lino in my kitchen. Am thinking of putting tile down myself.

- Not okorder Carole Q.

- Q: we layed tile after hurricane katrina whats the protocal about if you should tile the whole house with the same color tile my 10 yr old wants different tile then we layed in the bedroom. Does this effect the value of your home or does it matter?

- It doesn't have to match. I just put 12 tile down in a 2nd floor bathroom, and it doesn't match the 6 tile in the 1st floor bath. It *is* similar in color, but that's about it. If the tile will be in adjoining rooms, then I would have it match, or at least complement each other - same color/different size, maybe. But if it was at opposite ends of the house, I wouldn't worry. One caveat - a 10 year old may want some sort of tile that you really don't want - electric blue, for example. Sorry, I wouldn't do that at all!

- Q: I need two more floors tiles to match my kitchen floor. The floor was down before we moved in. how i can find out what type of tile it is?

- If you have any loose pcs not yet installed the backs can give me clues as to what it is. Along with the year it was originally installed ( approx) and the exact size of the tile.. Any thing over 8/10 years old you may as well look for some thing close in the exact size. Beyond that your looking at reclaimed tile discount outlets looking for dropped tile lines. There is a few places that specialize in buying and selling of dropped lines of tiles. They change and discontinue tiles every 7/10 years to keep up with changing styles and colors patterns. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: I am trying to decide between installing hardwood or tile floors in my kitchen remodel. Any thoughts on pros and cons of each? Thanks.

- Wood.. Tile is so inconvenient. Tile is so hard to clean. Because it has those cracks inbetween each square. Go with wood.

- Q: Why the tile is not clean clean

- You must be polished tiles, polished polished after polishing, the surface has a lot of naked eye can not see the tiny holes, so most manufacturers through the wax to protect, but a long time or will seepage. Method: 1, to the agent to decontamination powder, the general agents have. 2, with the decontamination powder to remove the watermark, remove the watermark after the use of a clean mop repeatedly drag 5 times to ensure that the decontamination powder clean. 3, after cleaning to protect the scene, can not use the foot, after 24 hours after the brick completely dry, and then hit a layer of protective wax, in 24 hours before they can move. (Note: If the brick is not dry can be blown dry with a hair dryer, wax can also ask the dealer to). After the renovation recommended antique tiles, the current domestic good antique tiles have Saide Si state, Marco Polo, L & D, gold pottery and other brands.

- Q: I‘m installing 13 x 13 cermic tiles. We‘ve laid the tile to try to configure the best layout. However, the one with the best layout with the easiests cuts leaves one very complicated one. The tile lies directly on the air duct, with the cut being a large rectangular hole in the middle of the tile. If we adjusted the layout to have 2 tiles lay over the duct, it creates more complicated cuts everywhere else.How do you suggest I cut this tile?We have only a wet tile saw.

- Get a ceramic tile drill bit and a coping saw with a diamond encrusted blade. Drill a hole in the tile. Slip the coping saw blade through the hole and attach it to the saw. Cut out the rectangle for the air vent.

- Q: I have a pistol grip glass cutter with a carbide cutting wheel....can this be used to cut ceramic tile, or am I better off to get tile nippers?

- You score tile with the glass cutter. For other than straight cuts those nippers are still useful.

- Q: i am looking for the best way to lay 600 x 600mm polished porcelain tiles on a caber chipboard floor can anyone help?

- Chipboard is not a suitable underlay for tile. Check the bag of mortar for acceptable substrates, at the very minimum you will need a tile backer. If there is any deflection in the chipboard I would recommend putting plywood down before using tile backer. Remember that tile backers don't add much strength as far as flexing is concerned, they are used so the underlayment has a similar expansion and contraction rate as the tile itself. Wood will not give you this and cracks will develop over time.

1. Manufacturer Overview

| Location | Jiangxi,China |

| Year Established | 2001 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO 9001:2000;ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai,Shenzhen |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Acid and Heat-resistant Bricks with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Tons watt

- Supply Capability:

- 100000 Tons per Year watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches