Powder Coated Aluminum Coil - AA5XXX Mill-Finished Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

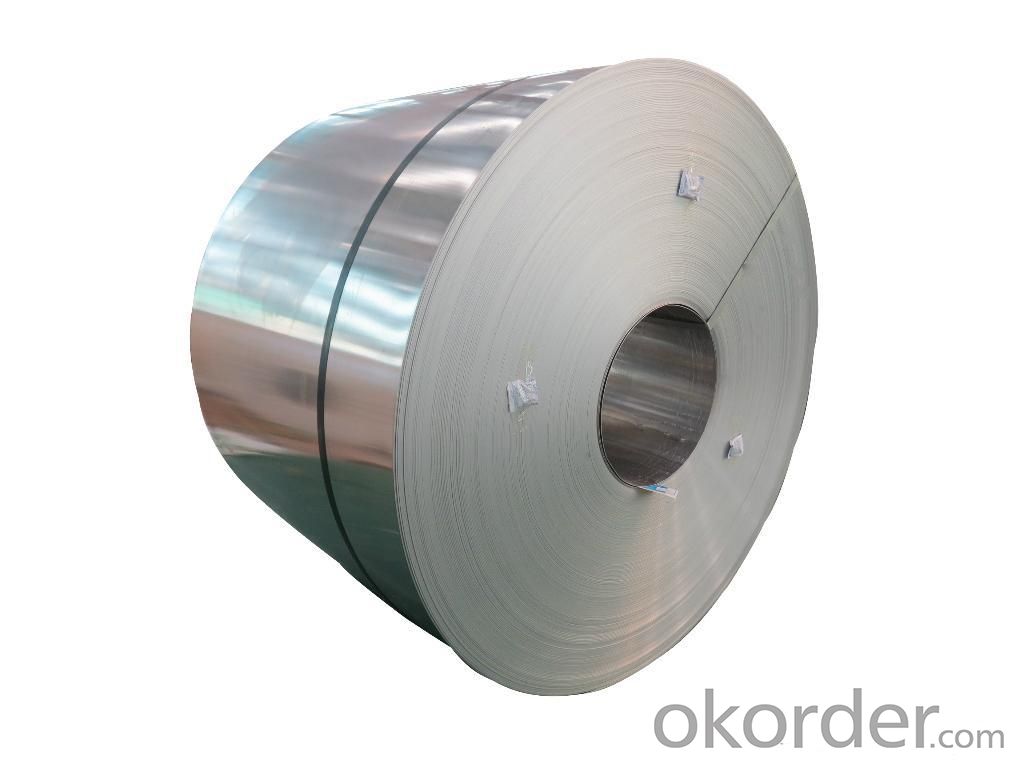

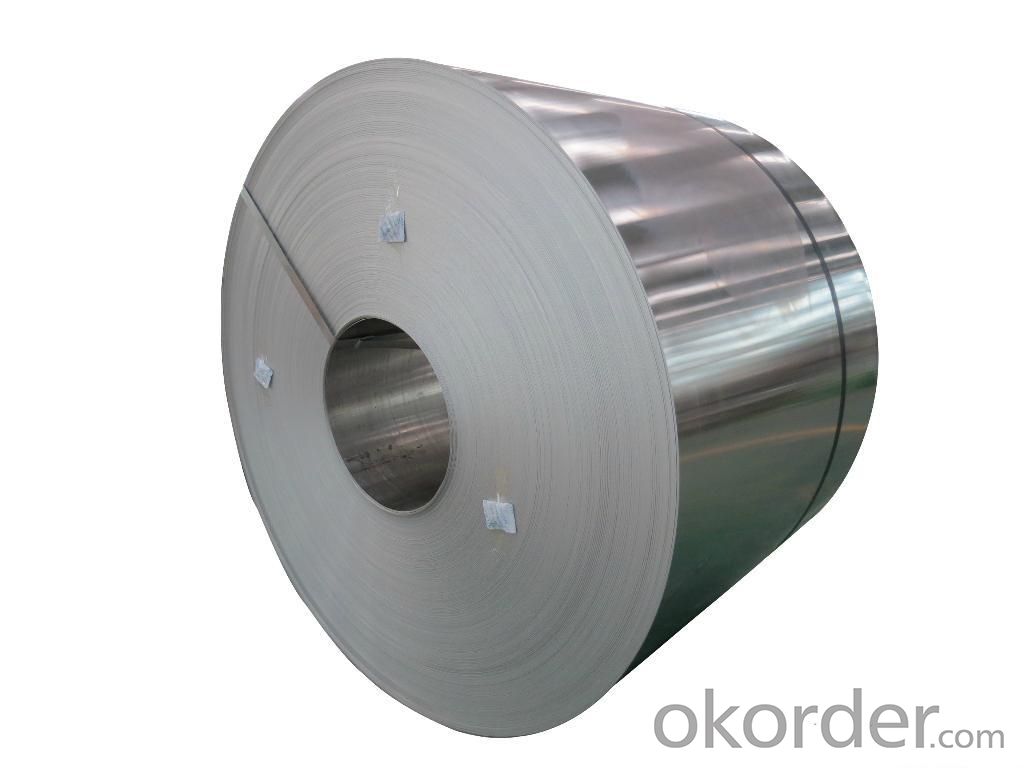

1.Structure of AA5xxx Mill-Finished Aluminum Coils Used for Construction Description Description

AA5xxx Mill-Finished Aluminum Coils Used for Construction Description has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA5xxx Mill-Finished Aluminum Coils Used for Construction Description is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA5xxx Mill-Finished Aluminum Coils Used for Construction Description

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.AA5xxx Mill-Finished Aluminum Coils Used for Construction Description Images

4.AA5xxx Mill-Finished Aluminum Coils Used for Construction Description Specification

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc. |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA5xxx Mill-Finished Aluminum Coils Used for Construction Description

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA5xxx Mill-Finished Aluminum Coils Used for Construction Description.

B.When will you deliver the products?

AA5xxx Mill-Finished Aluminum Coils Used for Construction Description will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: The canoe is aluminum. It has some paint remaining on it from what i am assuming is the original factory paint. The paint is just in patches, so my question is do i sand only where the paint is, or the whole canoe? Will sanding the aluminum damage it? Or should I not sand it at all, and just use paint stripper? After getting the old paint off, what kind of primer should i use? or is it not necessary to prime? What kind of paint should I use? I plan on it being multi tone(a leafy camo, of olive drab, flat black, and a gray tone).

- Go to a paint trade shop tell them what your trying to achieve. They will probably suggest a primer to etch the aluminium. Once its been etched you can paint it any colour you wish. If you don't etch the aluminium, the paint will probably fall off. The etching gives the paint something to adhere to. Cheers!!

- Q: Is it possible to recycle aluminum coils?

- <p>Yes, aluminum coil can be recycled. Recycling aluminum is a highly efficient and environmentally friendly process. It requires only 5% of the energy needed to produce new aluminum from raw materials. Recycled aluminum coils can be used to manufacture new aluminum products, reducing waste and conserving resources. The recycling process typically involves melting the aluminum, which can then be reshaped into new coils or other forms. This makes aluminum one of the most recycled materials in the world.</p>

- Q: This question asks for a comparison between aluminum coil and iron coil, highlighting their distinct properties and uses.

- <p>Aluminum coil and iron coil differ in several aspects. Aluminum coil is lightweight, corrosion-resistant, and has excellent electrical and thermal conductivity, making it ideal for electrical wiring, heat sinks, and food packaging. Iron coil, on the other hand, is heavier, stronger, and more durable, commonly used in construction, automotive, and heavy machinery due to its high tensile strength. Iron also has magnetic properties, useful in applications like transformers and electromagnets. While aluminum is non-magnetic, it is more cost-effective and has better recyclability compared to iron.</p>

- Q: The temperature of the water drops from 93.0°C to 78.0°C. What quantity of heat energy did the piece of aluminum absorb?

- The specific heat of Aluminum is 0.215 cal/g-°C. The calories absorbed (q) would be q = m * c * (T2 -T1) = 22.0 g * 0.215 cal/g-°C * (78.0 °C - 0.3 °C) If you have a different value for the Specific heat of Aluminum, use it in the formula for your calculations. If you knew the mass of the water, you could check your calculations because the heat gained by the Al would be equal to the heat lost by the water, using q = m * c * (T2 -T1), where m is the mass of the water, c = 1.00 calorie/gram °C, T2 = 78.0 °C and T1 = 93.0 °C. The sign of q will be negative.

- Q: the ingredient on the back says aluminum?also ..what is sodium benzoate?Is all this stuff that terrible for you? Or does it mean something else?

- The aluminum is in the baking powder. Very common but you can buy it without it, it is much healthier for you. Aluminum is correlated to Alzheimer's and ADD. Baked goods taste much better without the aluminum too. Benzoate of soda, a preservative that can alter your DNA. Not too good for you, no matter what the FDA may say about it. All told, if you are concerned for your health, keep to organic as much as possible and made from scratch too. Way too much junk is put in our food and health products.

- Q: i have some questions about aluminum can recycling??:how much can you get from doing that??where can i take them in indianapolis, in???and what else could i recycle??its good for the earth and i need some money!! :) :D thanks!!! :)

- They are worth about $0.01 per can. You can take them to any scrap metal yard.

- Q: Can aluminum coils be used in the production of solar panels?

- Yes, aluminum coils can be used in the production of solar panels.

- Q: What is the difference between hot rolled and cold rolled aluminum coils?

- The main difference between hot rolled and cold rolled aluminum coils lies in the manufacturing process. Hot rolled aluminum coils are produced at temperatures above the recrystallization temperature, resulting in a more malleable and ductile product. Cold rolled aluminum coils, on the other hand, are processed at room temperature, making them stronger and more rigid. This difference in processing also affects the surface finish and dimensional accuracy of the coils.

- Q: What are the factors that determine the price of aluminum coils?

- The price of aluminum coils is influenced by a multitude of factors. One of the primary determinants is the cost of raw materials. The price of aluminum is susceptible to supply and demand, global economic conditions, and production costs. Fluctuations in these factors can directly impact the price of aluminum coils. Another contributor to the price of aluminum coils is the manufacturing process. The cost of converting aluminum into coils encompasses expenses such as labor, energy, and equipment. The intricacy of the manufacturing process and the efficiency of the production line can affect the overall cost, consequently influencing the price of aluminum coils. Market conditions also play a critical role in determining the price of aluminum coils. Factors like market competition, industry trends, and geographic location can impact pricing. For instance, if there is a high demand for aluminum coils in a specific region but a limited supply, the price may increase due to the scarcity of the product. Moreover, transportation and logistics costs contribute to the final price of aluminum coils. The distance between the manufacturing facility and the customer, as well as the mode of transportation, can affect shipping expenses. These costs are typically incorporated into the overall price of the coils. Lastly, government policies and regulations can exert influence over the price of aluminum coils. Tariffs, import taxes, and trade agreements may impact the cost of importing or exporting aluminum coils, thus affecting the final price. In conclusion, the price of aluminum coils is determined by a variety of factors, including the cost of raw materials, manufacturing processes, market conditions, transportation costs, and government policies. Manufacturers and consumers should take these factors into account when analyzing and forecasting the price of aluminum coils.

- Q: What are the different types of aluminum coils available in the market?

- In the market, one can find various types of aluminum coils, each possessing its own distinct characteristics and applications. 1. Basic Aluminum Coils: These coils are simple and commonly used for general purposes. They have a smooth surface and find applications in industries like construction, automotive, and packaging. 2. Aluminum Coils with Enhanced Aesthetic Appeal: These coils are coated with paint or other finishes to improve their visual appeal and provide extra protection against corrosion. They are widely used in the manufacturing of building facades, signage, and decorative items. 3. Textured Aluminum Coils: These coils have a textured or patterned surface, which gives them a decorative appearance and makes them slip-resistant. They are often utilized in applications where both aesthetics and functionality are important, such as flooring, staircases, and decorative panels. 4. Anodized Aluminum Coils: Through the anodizing process, a protective oxide layer is formed on the surface of these coils. This enhances their resistance to corrosion and makes them suitable for outdoor applications, including architectural elements, electronic components, and the aerospace industry. 5. Pre-painted Aluminum Coils: These coils come with a pre-applied paint coating, eliminating the need for additional painting or finishing. They are frequently used in industries that require high-quality, durable, and consistently colored products, such as automotive, appliances, and electronics. 6. Aluminum Coils for Heat Transfer: Specifically designed for heat transfer purposes in air conditioning and refrigeration systems, these coils have high thermal conductivity. They are often made from alloy grades that offer excellent corrosion resistance in harsh environments. Considering the specific requirements and intended use of the aluminum coil is crucial before making a purchase. This ensures that the appropriate coil type is selected for the desired application, optimizing performance and longevity.

Send your message to us

Powder Coated Aluminum Coil - AA5XXX Mill-Finished Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords