A large number of inventory foam

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

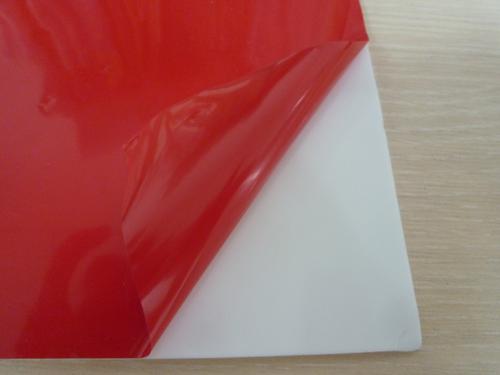

CONSTRUCTION:

Carrier: Acrylic foam

Liner: PE film, red colour.

TYPICAL PHYSICAL PROPERTIES:

Color: White

Total Thickness: 0.64mm ± 50 micron

180°Peel Adhesionafter 20 minutes (gf/25mm):2,500

180°Peel Adhesionafter 24 hours (gf/25mm):3,500

TemperatureTolerance :100℃

(24 hoursconditioning at indicated temperature with 100g static load)

PACKING:

Jumbo Roll:0.800 x 33m

Packaging:Wrapped with corrugated cardboard.

REMARKS:

1. The data above are typical results and subject to change withoutnotice.

2. Tolerance: Weight and Thickness: ±5%; Width: ±5mm;

Length: Cut Roll & LogRoll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be storedat room temperature and be kept away wet and/or heat source.

4. It is essential, as with allpressure-sensitive tapes, that the surface to which the tape is applied must beclean, dry, and free of grease and oil.

5. The users should take test anddo trial-application on the above products before coming into application so asto witness and ensure suitability for their special purpose and technique.

- Q: What are the uses of ethylene propylene rubber?

- In the electrical and electronic industries, the main use of ethylene propylene rubber excellent electrical insulation, weather resistance and corrosion resistance, in many electrical components used in this kind of rubber. For example, the production of cables with ethylene propylene rubber, especially submarine cables, is replaced by EPDM or EPDM/PP instead of PVC/NBR. The insulation performance and service life of cables have been greatly improved. In the transformer insulation pad, electronic insulation sheath is also a large number of ethylene propylene rubber production.Ethylene propylene rubber combined with other rubber is also a great field of ethylene propylene rubber applications. EPDM can be used in conjunction with other rubbers to improve performance and reduce costs. But due to various complex agents on the affinity of different polymers, covulcanization depends on the polymer crosslinking efficiency of different polymers and may not reach the molecular level compatible blend, but there were no phase separation system. The unequal distribution of complexing agents has a major impact on the properties of ethylene propylene and rubber.

- Q: What are the applications of rubber airbags in the automotive field?

- Rubber accounts for 5% of the total weight of automotive materials, with an average of 100200 rubber parts per car, with a total number of 200500. Along with the automobile reliability, environmental protection and energy saving requirements continue to increase, and rubber materials, product structure optimization, improve the heat resistance, low temperature resistance, long aging, oil resistance, leakage resistance, long-term fatigue, and further reduce the cost has become the main topic of the development of automotive rubber. Fluorine rubber, silicone rubber, acrylic rubber and other special heat-resistant elastic body will still be the mainstream of the future direction of the development of automobile rubber.

- Q: Why is rubber forest a green desert?

- Long ago, the people have the knowledge of the use of wild rubber. Before Columbo came to the new world, no one outside the Americas knew that there was a species called rubber, and never thought that there would be a magical liquid out of the tree trunk that could change the progress of human civilization one day.

- Q: How to enhance the performance of water resistant silicone rubber products

- In general, silicone rubber is almost free from the influence of free steam and moisture without pressure. The same is true when the steam is under low or moderate pressure. However, as the vapor pressure rises, the impact on the mechanical properties of the rubber becomes larger. Therefore, silicone rubber is not recommended for long-term use in situations where steam is more than 50psi.

- Q: How to maintain and store the rubber material?

- When storing, matters needing attention are:(1) should be stored in a ventilated, dry environment, the relative humidity of the air is 50% ~ 80%.(2) should be stored in non corrosive media, and away from the heat source, the temperature is about 5 degrees Celsius conditions(3) packing should be kept as far as possible without box stacking

- Q: How long does the rubber last?

- Depends on what kind of rubber material, each material's aging resistance is not the same

- Q: Rubber products on tiles, why tiles yellow?

- Rubber is a mixture of substances that can precipitate and cause yellowing. The term "rubber" is called frost"

- Q: EPDM rubber foam?

- Its characteristics: due to the internal foaming material containing a large amount of air or other gas, and should not be in circulation, especially the closed cell foam, with independent foam completely separated, material can obviously slow down on the heat conduction coefficient of heat conduction, very basic, more softness of the material itself, and good elasticity, can be used as the car, insulation materials, household appliances, ship electronic equipment, medical equipment, fitness equipment, such as the ideal air conditioning pipeline...

- Q: There is a crack in rubber products

- It is possible that the sulfur is too fast, the outside is ripe and the inside is slow cooked because of the uneven expansion

- Q: What's the difference between natural rubber and three yuan ethylene propylene rubber?

- The electric property of natural rubber is a kind of non polar material, and it is a better insulating material. When the natural rubber vulcanization after the introduction of polarity factors, such as sulfur, accelerator, so that insulation performance.

Send your message to us

A large number of inventory foam

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords