90TJ3 Ultra Light High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

90TJ3 is a type of ultra high pressure pump of JETECH technology (an American company).

This type is of various favorable features, such as light weight, compact structure, small size, high efficiency.

◆The power end case is precisely machined. The power end is force lubricated, transmitted stably and reliably by low friction herringbone gear mechanism, with less temperature increase, suitable for long time operation.

◆The liquid end is produced based on American technology, easy for maintenance and repair, able to work in long time.

◆This pump is applicable in ultra high pressure water cleaning, metal cutting, ship cleaning, rust removal, all kinds of tanks, containers, vessels, evaporators, heat exchangers cleaning in chemical, sugar, and power plants.

◆It can pump fresh water or emulsion liquid similar like fresh water.

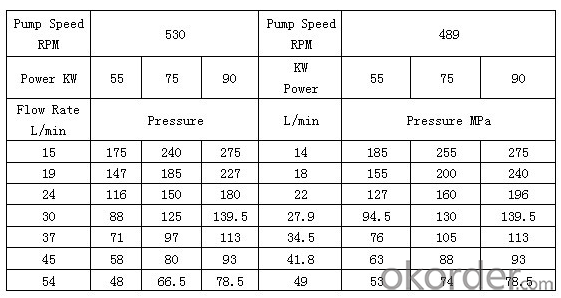

◆Technology Parameters

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q: How compact are air pumps for easy storage?

- Air pumps, known for their incredibly compactness, are ingeniously designed to facilitate effortless storage. These pumps are generally of such diminutive proportions that they can effortlessly nestle within the confines of one's palm, or be effortlessly stowed away in a bag or toolbox. In fact, certain models are so minuscule that they can be directly affixed to a bicycle frame or conveniently slipped into a pocket. The compactness of these pumps renders them an optimal choice for individuals seeking portable solutions or grappling with limited storage capacity.

- Q: Can an air pump be used for inflating inflatable pools with water sprayers?

- No, an air pump cannot be used for inflating inflatable pools with water sprayers. Air pumps are specifically designed for inflating objects with air, not for filling them with water. To inflate an inflatable pool with water sprayers, you would need a water pump or a hose connected to a water source. Water pumps are designed to handle the flow and volume of water needed to fill up pools, while air pumps lack the necessary features to accomplish this task.

- Q: Probably is such a big cylinder, the left is 16 open book, fish tank is 30 cm high, mouth diameter is 18 cm, pump small, may be 2W? Fish is 3, the kind of carp, in this condition, about how long will the oxygen pump open?

- 1. The three in one pump with filter and oxygen must always be on2 、 the skin bowl type air pump can not be opened without oxygen3, for anti gas lift, water demon skin bowl type pump, the best has been open4, leather bowl type air pump generally on the 3W power, 14 genius once electricity, if not noisy, long open no harm.

- Q: Can an air pump be used for inflatable party decorations?

- Yes, an air pump can be used for inflatable party decorations. An air pump is a convenient and efficient tool for inflating large quantities of party decorations such as balloons, inflatable arches, or inflatable characters. Using an air pump can save time and effort compared to manually blowing up each decoration. Additionally, an air pump ensures a consistent amount of air is pumped into each decoration, resulting in a uniform and professional look. It is important to note that the appropriate attachment should be used to ensure a secure connection between the air pump and the inflatable decoration.

- Q: Can an air pump be used for inflating air mattresses with built-in massage features?

- Yes, an air pump can be used for inflating air mattresses with built-in massage features. Air mattresses with built-in massage features typically have valves or openings that can be connected to an air pump. By attaching the air pump to the mattress, you can easily inflate it to the desired level of firmness. However, it is important to ensure that the air pump you use is compatible with the valve or opening of the mattress. Some air pumps come with different nozzle attachments to fit various types of valves, so it is advisable to check the specifications and instructions provided by the manufacturer of both the air mattress and the air pump to ensure proper compatibility.

- Q: What is the maximum pressure an air pump can achieve?

- The maximum pressure attainable by an air pump relies on several factors, including the pump's design, power source, and intended purpose. Different air pumps, such as those for bicycles, tire inflation, or industrial use, have varying pressure limits. For example, a basic handheld bicycle pump typically reaches a maximum pressure of approximately 120 psi (pounds per square inch), which suffices for inflating bicycle tires. Conversely, an industrial-grade compressor can achieve pressures of several thousand psi. It should be emphasized that surpassing the recommended maximum pressure for a specific air pump can be hazardous and may lead to equipment malfunction or injury. Therefore, it is essential to refer to the manufacturer's specifications and guidelines to ensure the safe and appropriate utilization of the air pump.

- Q: How does an air pump handle varying air densities?

- An air pump handles varying air densities by adjusting its internal mechanisms to regulate the amount of air it pumps based on the surrounding air density.

- Q: Which account should be included in the packaged air pump and circular saw?

- If more than two thousand of the value is included in the fixed assets, if the price is less than two thousand of the current material included in the turnover - - low - value consumables

- Q: How does an air pump handle dust particles?

- An air pump generally filters out dust particles by using a combination of air filters and other mechanisms to prevent the particles from entering and clogging the pump's internal components.

- Q: Can an air pump be used for cleaning purposes?

- No, an air pump cannot be used for cleaning purposes. An air pump is designed to inflate or deflate objects such as inflatable mattresses, balloons, or tires by forcing air into or out of them. It does not have the necessary features or attachments to be used for cleaning tasks. Cleaning typically requires the use of specialized equipment such as vacuum cleaners, pressure washers, or steam cleaners, which are specifically designed to remove dirt, dust, and debris from surfaces.

Send your message to us

90TJ3 Ultra Light High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches