130TJ3 Type Ultra High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

130TJ3 is a type of ultra high pressure pump of JETECH technology (an American company).

This type is of various favorable features, such as light weight, compact structure, small size, high efficiency.

◆The power end case is precisely machined. The power end is force lubricated, transmitted stably and reliably by low friction herringbone gear mechanism, with less temperature increase, suitable for long time operation.

◆The liquid end is produced based on American technology, easy for maintenance and repair, able to work in long time.

◆This pump is applicable in ultra high pressure water cleaning, metal cutting, ship cleaning, rust removal, all kinds of tanks, containers, vessels, evaporators, heat exchangers cleaning in chemical, sugar, and power plants.

◆It can pump fresh water or emulsion liquid similar like fresh water.

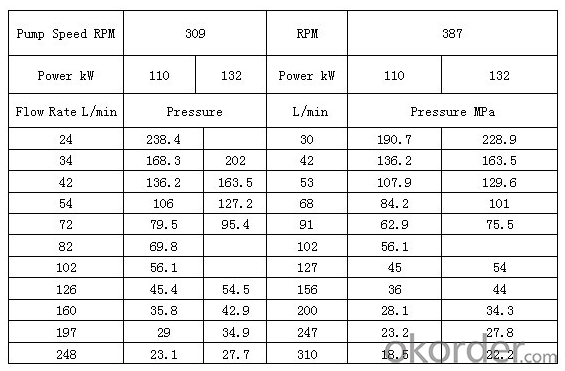

◆Technology Parameters

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q: The bell is sounding in a glass enclosure, and gradually to the glass in the pump pumping air, we heard more and more _, finally almost _, reasoning: when vacuum hood (without air), we will _.

- A little voice, no sound

- Q: Are air pumps suitable for inflating inflatable slides?

- Indeed, air pumps prove to be suitable for inflating inflatable slides. They stand as the most effective and practical means of inflating these expansive structures. Tailored explicitly for inflating inflatable objects, air pumps offer a consistent stream of air, facilitating rapid inflation of the slide. They boast user-friendly features and are available in diverse sizes and power variations to cater to the various types and dimensions of inflatable slides. Furthermore, air pumps grant precise control over the inflation procedure, guaranteeing the proper inflation of the slide without the risk of overinflation. Hence, it is strongly advised to utilize an air pump when inflating inflatable slides.

- Q: The quilt in the bag, sealed with air pump what is called air pumped.

- A vacuum storage bag consisting of a sealed storage bag and a suction barrel. The principle is to remove the air from the articles in the sealed storage bag so as to reduce the volume, to store conveniently and to place for a long time. This kind of thing can be bought in the big supermarket and the home goods market. When choosing, you should pay attention to the integrity of the outer packing of the goods, and prevent the damage of the sealed storage bag, so you'd better try it.Usage and function:The double hook in a storage bag is melted, a head hung in the bag, the other end of the bag can be hung in the hook. The lower part of the storage bag is welded with an exhaust pipe, and the inner part of the lower end opening is welded with the sealing strip. When in use, the vacuum storage bag together with the goods in the bag can be hung vertically, or horizontally stacked, suitable for different requirements of clothes or clothing items on the storage state of moisture, mildew, moth vacuum storage. The utility model has the advantages of simple structure, convenience and practicability. Completely changed the leather or suit clothing is not easy to store, easy to damp, mildew, moth dilemma.

- Q: How does an air pump create pressure?

- An air pump creates pressure by using mechanical force to compress the air molecules in a confined space, thus increasing their density and causing the pressure to rise.

- Q: Can an air pump be used for inflating air toys with multiple air chambers?

- Inflating air toys with multiple air chambers can indeed be accomplished using an air pump. The utilization of an air pump presents a convenient and effective method for the inflation of air toys with multiple chambers due to its ability to provide controlled and evenly distributed airflow. When equipped with the appropriate nozzle or adapter, an air pump can effortlessly access and inflate each individual air chamber of the toy, ensuring that all chambers are adequately filled with air. This aspect is particularly crucial for maintaining the stability and balance of the toy, as a uniform distribution of air pressure across all chambers aids in preserving its shape and integrity. Furthermore, an air pump typically offers adjustable pressure settings, enabling the user to inflate the toy to the desired level of firmness. In general, the utilization of an air pump for the inflation of air toys with multiple chambers is not only feasible but also highly recommended for a hassle-free and dependable inflation process.

- Q: How does an air pump handle different air viscosities?

- An air pump is designed to handle different air viscosities by using its mechanical components and adjusting its operation accordingly. The key factors that affect air viscosity are temperature and humidity. Firstly, the mechanical components of an air pump, such as the motor, impeller, and valves, are designed to handle a wide range of air viscosities. These components are typically made from materials that can withstand different levels of viscosity, ensuring their durability and functionality. The impeller, for instance, is designed to spin at a specific speed, regardless of the air viscosity, to generate the necessary airflow. Secondly, the air pump can adjust its operation based on the air viscosity it encounters. For example, if the air is more viscous due to high humidity, the air pump can increase its rotational speed or adjust the pressure settings to compensate for the increased resistance. This ensures that the air pump can maintain a consistent airflow and pressure output regardless of the air viscosity. Additionally, some air pumps may have built-in sensors or control systems that can automatically detect and adjust to different air viscosities. These sensors can measure factors like temperature and humidity, allowing the air pump to adapt its operation accordingly. This ensures optimal performance and efficiency even in varying air conditions. In summary, an air pump handles different air viscosities by utilizing its mechanical components designed to withstand a wide range of viscosities and by adjusting its operation to compensate for changes in air viscosity. By doing so, it can maintain a consistent airflow and pressure output, ensuring its effectiveness in various environments.

- Q: How loud is an air pump when in operation?

- The loudness of an air pump when in operation can vary depending on several factors. Generally, air pumps produce some level of noise due to the mechanical components and the movement of air. The noise level can range from a low hum to a noticeable buzzing sound. The loudness can also be influenced by the size and power of the air pump. Larger and more powerful pumps tend to produce a higher level of noise compared to smaller and less powerful ones. Additionally, the type of air pump can also affect the noise level. For example, diaphragm pumps are generally quieter than piston pumps. However, it is important to note that the noise level of an air pump is not typically excessive or disruptive. Most air pumps are designed to operate at a reasonable noise level, especially those intended for home aquariums or small applications. Nonetheless, it is always a good idea to consider noise levels when selecting an air pump, particularly if you plan to use it in a quiet environment or during nighttime when noise sensitivity may be higher. Ultimately, the loudness of an air pump is subjective and can vary from person to person. It is advisable to check the manufacturer's specifications or reviews to get a better understanding of the noise level before purchasing an air pump.

- Q: Can an air pump be used for inflating air mattresses with built-in lights?

- Yes, an air pump can be used to inflate air mattresses with built-in lights. The air pump's function is to inflate the mattress by filling it with air, and the presence of built-in lights does not affect this process.

- Q: Can an air pump be used for inflatable stage props or decorations?

- Certainly, inflatable stage props or decorations can indeed be easily inflated and deflated using an air pump. In fact, it is one of the most popular and efficient methods utilized for this purpose. Air pumps are specifically designed to swiftly and effortlessly fill up inflatables with air, enabling them to be effortlessly set up and taken down. They are available in diverse sizes and types, ranging from handheld pumps to electric pumps, and even larger industrial pumps, depending on the size and quantity of the inflatables you need to inflate. Moreover, air pumps often come equipped with various nozzles or adapters that can be adjusted to fit different types of inflatables, making them highly versatile and suitable for a wide array of stage props and decorations. Consequently, if you are seeking a convenient and effective means to inflate your stage props or decorations, an air pump would undoubtedly be an excellent choice.

- Q: Can an air pump be used for inflating inflatable kayaks?

- Yes, an air pump can be used for inflating inflatable kayaks. In fact, many inflatable kayaks come with a compatible air pump for easy inflation. Air pumps specifically designed for inflating inflatable kayaks are usually manual pumps or electric pumps that can quickly and efficiently fill up the kayak with air. It is important to use the right type of pump and follow the manufacturer's instructions to ensure proper inflation and avoid damaging the kayak.

Send your message to us

130TJ3 Type Ultra High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches