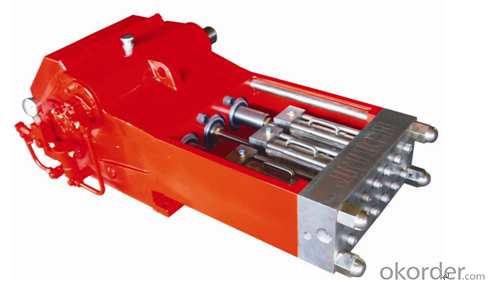

250TJ3 Type Ultra High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

250TJ3 is a type of ultra high pressure pump of JETECH technology (an American company).

This type is of various favorable features, such as light weight, compact structure, small size, high efficiency.

◆The power end case is precisely machined. The power end is force lubricated, transmitted stably and reliably by low friction herringbone gear mechanism, with less temperature increase, suitable for long time operation.

◆Liquid end is produced based on American technology, easy for maintenance and repair, able to work in long time.

◆This pump is applicable in ultra high pressure water cleaning, metal cutting, ship cleaning, rust removal, all kinds of tanks, containers, vessels, evaporators, heat exchangers cleaning in chemical, sugar, and power plants. It can pump fresh water or emulsion liquid similar like fresh water.

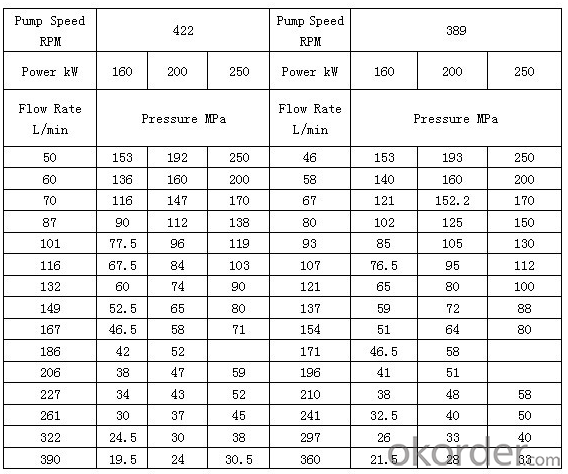

◆Technology Parameters

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q: How to choose the right air pump for a specific pneumatic valve?

- Choosing the right air pump for a specific pneumatic valve requires careful consideration of several factors. Here are some steps to help you make an informed decision: 1. Understand the requirements: Start by understanding the specific requirements of your pneumatic valve. Consider factors such as the valve size, operating pressure range, flow rate, and any additional features or specifications mentioned by the manufacturer. 2. Determine the air source: Identify the available air source for the pneumatic valve. This could be a compressed air system, a standalone air compressor, or any other source capable of providing the required air pressure and flow. 3. Evaluate the pump types: There are various types of air pumps available, including reciprocating pumps, rotary pumps, and centrifugal pumps. Each type has its advantages and limitations. Research and evaluate which type would be most suitable for your specific application. 4. Consider the pump capacity: Calculate the required pump capacity based on the flow rate and pressure requirements of your pneumatic valve. Ensure that the pump can deliver sufficient air volume and maintain the necessary pressure consistently. 5. Check compatibility: Ensure that the air pump is compatible with the pneumatic valve and its associated components. Consider factors such as fitting sizes, thread types, and any specific compatibility requirements mentioned by the valve manufacturer. 6. Energy efficiency: Evaluate the energy efficiency of different air pumps. Look for pumps that offer energy-saving features such as variable speed controls or efficient motor designs. This can help reduce operating costs in the long run. 7. Quality and reliability: Consider the reputation and reliability of the air pump manufacturer. Look for pumps that are built with high-quality materials and have a track record of reliability. This will ensure a longer lifespan and minimize the risk of breakdowns or maintenance issues. 8. Seek expert advice if necessary: If you are unsure about any aspect or need more specific guidance, consult with pneumatic system experts or valve manufacturers. They can provide valuable insights and recommendations based on their expertise and experience. By following these steps, you can choose the right air pump for your specific pneumatic valve, ensuring optimal performance and efficiency in your application.

- Q: How does an air pump prevent corrosion in water tanks or pipelines?

- By introducing air into the system, an air pump serves the purpose of preventing corrosion in water tanks or pipelines. When water and air are combined, the oxygen content increases, resulting in the creation of an oxidizing environment. This environment is essential in preventing the growth of anaerobic bacteria, which are known to cause corrosion. Furthermore, the presence of oxygen within the system encourages the development of a protective oxide layer on the interior surfaces of the tanks or pipelines. This layer acts as a barrier, effectively guarding against corrosion. To maintain this oxidizing environment and prevent the accumulation of corrosive elements that could lead to rust or degradation, the air pump continuously supplies air into the system. Ultimately, the utilization of an air pump effectively inhibits corrosion and prolongs the lifespan of water tanks and pipelines.

- Q: The reason why the wagon pump does not inflate

- 1, the air pump built-in shrapnel for a long time softened, and when the storage tank pressure reached 4 air pressure, due to the anti pressure of the storage tank to soften the shrapnel can not be played. That is to say, this kind of fault is most, the pressure can hit 4-6 kilograms.2, pump tube blocking, just as is the tube blocking good check is to pump the pipe apart from the dryer. Tell the driver started up if the line has a black smoke out of something out of that pump pipeline blockage, solution replacement pump pipeline, such as rigid organic waste oil is not oil outflow considering the pipeline blockage.3, the four loop of the road leak, four circuit protection valve is automatically closed, it is well recognized, is to see if there is a pressure gauge needle can hit 6 pressure, another needle is a no pressure.4, because the four circuit protection valve time is too long, the built-in spring rusty and stuck.5, the pipeline broken, blow when the edge of the leak, because the engine sound, you can not hear the leak, when the engine stops working, the air pressure will be gone.6, the pump leather bowl rotten. I can't hear the leak while I'm playing.7. The switch of the water tank is not closed. The air pressure is missing from the water tank. Inspection party

- Q: What are the different pressure measurement units used in air pumps?

- Different regions and applications utilize various pressure measurement units in air pumps. Pound per square inch (psi), bar, kilopascal (kPa), and atmosphere (atm) are the most frequently employed units. Pound per square inch (psi) is widely recognized for pressure measurement and commonly employed in North America. It signifies the force exerted by one pound on an area of one square inch. This unit finds extensive use in automotive and industrial applications. Bar is a commonly used pressure unit in Europe, particularly in metric countries. It is defined as 100,000 pascals, approximately equivalent to 14.5 psi. Bar is often utilized in measuring tire pressure and industrial settings. Kilopascal (kPa) serves as the standard pressure unit in the International System of Units (SI). It equals one thousand pascals and is globally employed in scientific and engineering applications. Air pump gauges frequently utilize kilopascals for pressure measurement. Atmosphere (atm) represents the average pressure exerted by the Earth's atmosphere at sea level. It is approximately equal to 14.7 psi or 101.3 kilopascals. The atmosphere unit is commonly used in weather forecasting and comparing gas pressures. Apart from these commonly used units, specific applications employ other pressure measurement units such as torr, millibar, and pascal. It is crucial to ensure the compatibility of the pressure unit with the air pump to accurately measure and control pressure.

- Q: What are the different types of air pumps available?

- There are several types of air pumps available, including manual hand pumps, electric pumps, foot pumps, and battery-operated pumps.

- Q: Can an air pump be used for inflatable play structures?

- Yes, an air pump can be used for inflatable play structures.

- Q: Can an air pump be used for inflatable arches?

- Yes, an air pump can be used for inflatable arches. In fact, an air pump is the most common and efficient method of inflating and maintaining the shape of inflatable arches. These arches are typically made of durable materials and have air chambers or tubes inside them. By using an air pump, air is forced into these chambers, causing the arch to inflate and take its desired shape. The air pump can be easily connected to the arch and can quickly fill it with air, ensuring a sturdy and stable structure. Additionally, the air pump can be used to adjust the pressure and maintain the inflation of the arch throughout its usage.

- Q: Can an air pump be used for pneumatic actuators or cylinders?

- Yes, an air pump can be used for pneumatic actuators or cylinders. Pneumatic actuators and cylinders rely on pressurized air to generate motion, and an air pump is specifically designed to provide that pressurized air. By connecting the air pump to the actuator or cylinder, it can supply the necessary air pressure to drive the desired movement or force.

- Q: BMW 740 after the air pump and air pump relay installation position

- Trunk。 Spare wheel position. All together

- Q: Can an air pump be used for inflating air curtains?

- No, an air pump is not typically used for inflating air curtains. Air curtains are typically inflated using a blower or fan system specifically designed for that purpose.

Send your message to us

250TJ3 Type Ultra High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches