Raw Materials for Refractory:87% Rotary Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

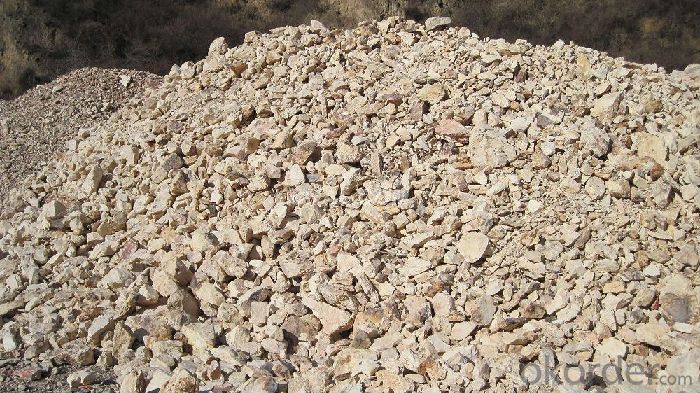

87% Rotary Kiln Alumina Calcined Bauxite Refractory Raw Material

Specifications

1. We directly supply calcined bauxite

2. Al2O3:70%/75%/80%/85%/86%/88%/90%

3. Size:0-1-3-5-8-10/200mesh/325mesh/400mesh/500mesh

Size:

Lumps /Grains:0-1mm,1-3mm,3-5mm,5-8mm /Powders:100mesh, 200mesh,325mesh

Product Description:

Bauxite, alumina or bauxite miner , main ingredients are aluminum oxide, hydrate alumina containing impurities,

is an earthy mineral.White or grey, brown yellow or light red by iron.From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3, opaque, very brittle.

Very difficult to melt.Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution.Mainly used for aluminium, refractory material.

Calcined Bauxite Grade:

Shaft Kiln Bauxite

Rotarty Kiln Bauxite

Round Kiln Bauxite

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: what's the application of fireproofing abs materials?

- fireproofing abs material is quite good, its fireproofing ability is quite good, now it's sales in the market is very well, you can purchase as you want.

- Q: which kind of fire?bulkhead is better?

- Fire bulkhead also known as non-combustible fire retardance board, and it's made by various incombustible?material after the scientific pressing, and has good flame resisting properties, it's non-combustible time can reach over 3 hours, high mechanical strength,it has characteristics of non-explosive, water and oil resistance, good chemical corrosion resistance and non-toxic. As for the combustion test of YD-Ba-type inorganic fire?bulkhead, it's best to be deformation under the flame temperature of 1000 ℃, the indicators comply requirements of GA161-1997, combustion performance reaches A level standards of GB8624(non-flammable). J fire bulkhead is mainly applicable to the fireproofing protection and fireproofing isolation of cables with all kinds of voltage?classes laid on scaffold or bridge. It's widely used in cable project fireproofing and fire?retardant in the places with crowded cables, such as various power plants, chemical companys, iron and steel smelting enterprises, mines,etc. It's also the best fireproofing and fire?retardant materials of fireproofing and fire?retardant projects in indoor decoration of public places, such as large shopping malls, hotels, guesthouses, sports hall, closed clothing market, light industrial markets, theaters and so on. Construction method: Fire?bulkhead products can be cut by saw, according to the shape required to be made in the construction site, using steel brackets or expaned anchor bolt to fix it while assembling, steel brackets should be coated with fire-resistant coating for steel structure. You can also use various cable and fireproofing trays made of fire bulkhead, and used in the board gaps.

- Q: what is the requirements of roofing insulation materials fire rating?

- The fireproofing requirements of architectural design are regulated by architectural design fire?safety?rules, roofing insulation material only has the requirements of materials combustion performance, namely non-combustible material. No fire rating requirements.

- Q: How many hours of the fire endurance time of the rock wool laminboard?

- Limit is usually two hours. Pay attention to it please.

- Q: Who knows that among refractory materials, insulation boards from which refractory material industry is superior in quality?

- When casting ingot, after high temperature molten steel is poured into ingot mold, molten steel keeps shrinking during cooling, for example, killed steel is shrinking 3% --5%. because of fast heat dissipation of ingot head , some shrinkage holes appear at the head of ingot. Therefore, you should cut shrinkage holes which account for more than 15% of the ingot quality in the head while cutting steel ingot cogging. If effective measures were taken to insulate the head of ingot from heat, then the coagulation time of ingot head would lag behind in the body of the ingot solidification, which will greatly shrinkage holes, improve ingot yield so as to reduce energy consumption of steelmaking. Adiabatic plate can achieve this purpose. China Heng insulation board has the advantages of uplifting adiabaticity and small heat capacity, so that it greatly reduced heat loss of molten steel, And the tundish can be directly put into use without preheating, thereby saving a large amount of preheating fuel. So in the current process of continuous casting, the heat insulation board is the main material of tundish lining.

- Q: What are the types of steel refractory materials

- The major category is classified as permanent layer, working lining. Specific varieties: Air permeable brick (corundum). steel ladle brick (magnesia or corundum), permanent layer castable (high alumina), reinforcing material for ladle bottom, repair material for the edge of tank and so on.

- Q: What are the commonly used fire protection materials

- Firewall. The fire wall is made of non combustible material, and is directly installed on the base of the building or the reinforced concrete frame or fire proof walls . Fireproof limit of the firewall, according to the current "building regulations", is 4 hours, wheras the specification of Technical specification for concrete structures of tall building is 3 hours. doors resistant to fire, heat in a certain period of time These door usually prevent the spread of fire and gas in the fire resistant wall, staircase, pipe well. Fire door can be divided into steel fire doors, wood fire doors and composite materials fire door according to the material used. According to the limit of fire resistance can be divided into the class A fire door (1.2h), B fire doors (0.9), class C fire door (0.6h); (3) fire window. Windows resistant to fire, heat in a certain period of time It is usually installed in the fire resistance wall or doors; the fire shutter. This roller shutter can be refractory in a certain period of time. It is typically used for heat and fire insulation in escalator with difficulties to install fire resistant wall, fire resistant valve and smoke resistant valve. Fire resistant valve is installed in the ventilation and air conditioning system of air supply and return air duct, usually in the open state, fire, It will be turn off when the pipeline gas temperature reached 70 degrees, can meet the requirement for fire resistance and insulation for gas and fire. Smoke fire resistant damper installed in the exhaust system pipe, when the pipeline gas temperature reached 280 degrees, it will close automatically, insulating fire and gas.

- Q: Refractory inquiries

- Neutral refractory is refractory material which is difficult to react with acid or alkaline slag at high temperature, such as carbon refractory and chrome refractory. Some of the high alumina refractories are also attributed to this category.

- Q: What is glass furnace used high-grade refractory materials?

- Corundum brick, such as alumina hollow ball brick. In addition, in the key parts of the glass furnace needs to use chromium zirconium corundum material. I'm salesman of zibo lei bao refractories company. The softening temperature of corundum mullite brick is 1500 degrees. So glass melting furnace needs to use refractory materials which high temperature resistance is more than 1600 degrees.

- Q: What's the fire endurance of A grade fireproof glass curtain wall?

- An hour and a half, an hour, and half an hour. As a key step in the home fire prevention, fire door is particularly important. According to the fire endurance and heat insulation performance, it can be classified as follows: A class fire door with fire endurance of no less than 1.5h; B class fire door with fire endurance of no less than 1h; C class fire door with fire endurance of no less than 0.5h. We can choose according to different needs, while A class fire door and B class fire door are now commonly used. Fire door has great varieties, and the material it uses is also of wide range. It includes stainless steel fire doors, glass fire doors, steel fire doors, etc. The most important feature of fire door is its fire resistance period. The main difference between A class fire door and B class fire door lies in their fire endurance, of which the former is no less than 1.5h, while the latter is no less than 1h. Difference between A class fire door and B class fire door also lies in their fireproofing material. That is the thickness of the built-in fire prevention board, of which A class fire door is 52mm, while B class fire door is 46mm. Therefore A class fire door obtains longer fire resistance period than that of B class fire door and gains better fireproof performance. A class fire door and B class fire door also differ in the places they are used. A class fire door is generally used in important fire fighting access of machine rooms, warehouses and oil depots, etc. and flammable and explosive public places, while B class fire door is generally used in the ordinary fire fighting access of some ordinary buildings. But B class fire door is more widely used than A class fire door.

Send your message to us

Raw Materials for Refractory:87% Rotary Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords