Raw Materials for Refractory:78% Rotary/Shaft/Round Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

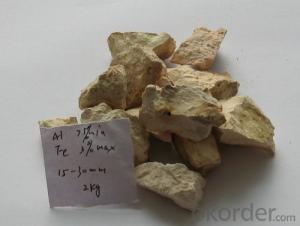

78% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Refractory Raw Material

Specifications

1. We directly supply calcined bauxite

2. Al2O3:70%/75%/80%/85%/86%/88%/90%

3. Size:0-1-3-5-8-10/200mesh/325mesh/400mesh/500mesh

Size:

Lumps /Grains:0-1mm,1-3mm,3-5mm,5-8mm /Powders:100mesh, 200mesh,325mesh

Product Description:

Bauxite, alumina or bauxite miner , main ingredients are aluminum oxide, hydrate alumina containing impurities,

is an earthy mineral.White or grey, brown yellow or light red by iron.From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3, opaque, very brittle.

Very difficult to melt.Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution.Mainly used for aluminium, refractory material.

Calcined Bauxite Grade:

Shaft Kiln Bauxite

Rotarty Kiln Bauxite

Round Kiln Bauxite

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: What kind of flexible fireproof material is really good?

- Flexible waterproof materials mostly are asphalt, linoleum and other organic material, which is also called linoleum coiled material waterproof layer. it uses the linoleum, glass cloth fabric as tire layer coil, using all kinds of cementing material phase of asphalt and so on. Make coil bind on roof structure plate leveling layer to form waterproof layer. Flexible waterproof material has high tensile strength, big elongation and light quality, which is convenient to construct. But it has relatively strict operation technology can resistant penetration and aging resistance than rigid materials, aging. Its life is short. Refers to a kind of waterproof material form relative to the rigid waterproofing materials such as waterproof mortar and waterproof concrete. In the form of its and grassroots attached two categories, it includs waterproof coating and waterproofing materials. According to different paste position of waterproof material, it can be divided into outside waterproof waterproof (outsourcing) and inside waterproof (insourcing waterproof) two kinds. Waterproof coil material must be stuck in the grass-roots that have enough stiffness of the. Before pasting, you should apply leveling layer and waterproof layer should be added protective layer of the outside, and need to make the rotation of the flexible material, the processing of subsequent and head closing, in order to ensure the continuity of the waterproof layer and sealing. In addition, there are all kinds of waterproof material and moistureproof coating material.

- Q: What advantage and disadvantages it has compared to common fire insulation materials

- Main advantage of A-level fire proof heat retaining plate is A-level non-conbustibility. Now residential areas strictly require the external walls to be high-level fire proof, to be specific, high fire resistance, non combustible. Standards for evaluation varies according to different types, which includes anti-corrosion, acid and alkali resistance, waterproof, anti termites and so on. Disadvantage is the insulation effect is quite ordinary. It will absorb water, get deformed, need some water prevention measures after constrcuting thermal insulating layer for it. Its thermal conductivity far below the benzene plate, and plastic extruded palte, half the thickness of the polyurethane insulation layer can reach heat perservation effectiveness of the benzene plate and extruded plate of the same thickness.

- Q: what is the grading standards of external wall thermal insulation materials?

- 1. combustion performance of insulation material rates A EPS sea capacity module, rock wool, glass wool, foam glass, ceramic foam, foam cement, perlite obturator, etc. 2. combustion performance of insulation materials rates B1 Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde, gelatine powder polyphenyl granule3 combustion performance of insulation material rates B2 Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. See the 2009 edition construction technical measures 4.3.6 A graded insulation material is fire proof, but its thermal insulation performance is not so as organic XPS \ EPS. I feel the best insulation materials are Hairong EPS module. it is both insulating and fireproof and cheap. Insulation materials in the domestic market each has its shortcomings. Choose of materials should based on actualities in construction.

- Q: What is acid refractory material?

- Corundum products containing more than 95% of alumina are a kind of high quality refractory materials with a wide range of uses. Chrome brick by using chromium oxide as the main component of the corrosion resistance of steel slag is good, but the poor heat shock resistance, high load low deformation temperature. Carbon refractories with carbon bricks, graphite and silicon carbide products, low coefficient of thermal expansion, high thermal conductivity, heat vibration performance, high strength, corrosion resistance to acid and salt, without wetting of the metal and slag, light. It is widely used as lining material of high temperature, and also used as lining of autoclave in petroleum and chemical industry. Basic refractories in Magnesium Oxide and calcium oxide as the main ingredient, commonly used is brick. Magnesium Oxide 80% to more than 85% containing magnesia brick, has good resistance to alkaline slag and slag, refractory clay brick and brick high ratio. Mainly used in open hearth furnace, oxygen converter, electric furnace, non-ferrous metal smelting equipment and high temperature equipment. High temperature oxide materials in refractory special applications, such as aluminum oxide, lanthanum oxide, beryllium oxide, calcium oxide, zirconium oxide, refractory compounds, such as carbides, nitrides, borides, silicides and sulfides; high temperature composite materials, including metal ceramics, high temperature inorganic coatings and fiber reinforced ceramics.

- Q: what's the varieties of fire-proof?sealing?material?

- Fire blocking material currently on the market include: fire stopping board, foam blocking material, flame resisting module, fire-resisting sealant, flexible organic caulking, WXY-II and fire retardant bag, etc. fire-proof?sealing?material is widely used in building construction and can ensure high-temperature flame and smoke from fires not spread to another fire?compartment, different buildings generally use different sealing methods. Pipeline is generaly sealed by pouring concrete board or mortar.

- Q: Refractory materials are needed for casting metallurgy.

- Refractory material used in foundry work is that refractories for cupola furnace? Cupola is a high temperature furnace which is used for melting molten iron, and refractory material adopted is mainly low iron high grade clay brick and clay lightweight insulation bricks, etc.foundry ingot refractory material is pearl sand (also known as pearl jewelry sand, fused ceramic, ceramic sand) it is made of high quality bauxite material by arc melting furnace.

- Q: how to divided the external wall thermal insulation materials fire rating

- Level A: Incombustible building material is a material that does not occur any burning. Level A1: Noncombustible means no open fire. Level A2 It is noncombustible, and should measure smoke to be qualified. Level B1: Nonflammable building material: Non-flame material has good flame resistance. It is difficult to fire under the condition of open fire in the air or high temperature, and it is not easy to quickly spread, and when the combustion?source is removed, the combustion will stop immediately. Level B2: Combustible?building?materials: Flame material has a good flame resistance. In case of fire in the air or at high temperature, it will immediately burst into flames, and easily lead to the spread of fire, such as wooden column, timber roof truss, timber beam and wooden stairs. Level B3: inflammable building material has no any flame resisting effects, and is easy to burn, so the fire risk is high.

- Q: What are the fire resistances of grc partition panels?

- fire resistance of partition panel≥3.5h, it has an excellent fireproof performance and can be applied to fire-proof bulkhead.

- Q: What is the acceptance standard of refractory?

- It depends on the variety of materials. In general the main test items include chemical composition, refractoriness, refractoriness under load, creep, volume density, linear change, strength, slag resistance, thermal conductivity and thermal expansion. If it is shaped products, it is required to inspect the size deviation and whether it has edge. Detection method accords with the relevant national standards and there are lots of them. You can refer to the standard compilation.

- Q: Does anyone knows which company produces the better refractory materials?

- I recommend Xinjiang Yuanyangrefractory material Co., Ltd. Address: Near Xishan Road No.100, Saybagh District,Urumqi. Their products are both in good quality and reasonable price. In addition, there are Xinjiang Zhongwang refractory material factory, Address: Xi hongxi Road No. 769, Urumchi City. They all have a good reputation. You may think about it. 。

Send your message to us

Raw Materials for Refractory:78% Rotary/Shaft/Round Kiln Alumina Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords