1/8 Aluminum Strips - Quality China Prepainted/Printed Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

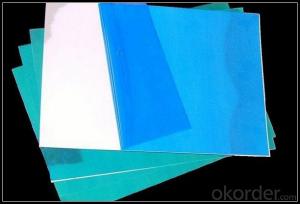

Our mill can produce all kinds of color pe pvdc painting aluminum coils ,which is used for build roof sheets:

1.Usually materials is:Alloy A3003H24 A3003H26 A3003H12 A3004H24 A3003h26

With thickness:0.6mm 0.7mm 0.8mm 0.9mm1.0mm

With width:22-1600mm

Color:according to customer

Coating:PE coated 25-28 Micro

Plastic film:0.05 or 0.06 mm film covered on the surface,could with customers' logo

Package:With inner-diameter 405mm or 505mm ,durable package for transport on sea,or as per required

.

2.specification: color pe pvdc painting aluminum coils

| Product | prepainted aluminum coil/printed aluminum coil |

| Thickness | 0.2mm-4.0mm |

| Popular Thickness | 0.25mm/0.3mm/0.4mm/0.45mm/0.5mm/0.6mm/0.9mm/1.0mm/2.0mm... |

| Width | under 1700mm |

| Popular size of sheet | 1000*2000,1200*2400,1219*2438,1220*2440 1000*3000,1250*3000,1500*3000 etc. |

| weight | about 2000kg |

Material | 1050,1060,1100,3003,3004,3105,5052,5005, 5754,5083,6061,6063 etc |

| Temper | O,H12,H14,H16,H18,H24,H26, H32,H34,H111,H112,T3,T5,T6 etc |

| Inner Diameter | 505mm |

| Color | white, gray ,gold ,blue,red,etc.(as per customer’s requirement) |

| Total coating thickness | PVDF coating: more than 25micron PE coating : more than 18 micron |

| Packing | Export standard wooden pallets (as per requirements) |

| Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

| Minimum Order Quantity | 5 tons per size |

| Delivery time | 20-30days after receiving L/C or deposit |

| Loading Port | Qingdao China (any port in China ) |

| Application | Lighting, printing, packing, decorative, electronics surface, ect. |

| Remark | Specific requirement of alloy grade,temper or specification can be discussed at your request |

3.Features: color pe pvdc painting aluminum coils

1) Super peeling strength

2) Excellent surface flatness and smoothness

3) Superior weather, corrosion, pollutant resistance

4) Even coating, various colors

5) Fireproof, excellent heat and sound insulation

6) Superior impact resistance

7) Lightweight and easy to process

8) Easy to maintain

4.Application: painted polyester aluminium foil/pe coating aluminium foil

1) Building exterior curtain walls

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels

7) Industrial materials, materials for vehicles and boats

features

- Q: Aluminium belt car

- Automobiles are machines of high speed. In order to give their performance the best, people prefer to improve their roads to adapt to cars rather than re - adapt them to bad roads. Now some people are interested in track cars, keen on retro, playing games and satisfying personal needs. 3 、 tracks are now used on slow tractors and tanks. In order to improve the speed of the military, or the use of wheeled armored personnel carriers.

- Q: Are aluminum strips suitable for manufacturing automotive components?

- <p>Yes, aluminum strips are commonly used for automotive parts due to their lightweight, high strength, and corrosion resistance. They are utilized in various components such as engine parts, body panels, and suspension systems to reduce weight and improve fuel efficiency. Additionally, aluminum's recyclability makes it an environmentally friendly choice for the automotive industry.</p>

- Q: This question asks for the duration aluminum strips can last or their service life.

- <p>The lifespan of aluminum strips can vary significantly based on factors such as the environment in which they are used, the quality of the material, and the specific application. In general, if properly maintained and not exposed to harsh conditions, aluminum strips can last for several decades. For instance, in construction, aluminum strips used in framing can have a lifespan of 20 to 40 years. However, in more aggressive environments or with frequent wear and tear, this lifespan can be considerably shorter. It's important to note that aluminum is a recyclable material, and its lifespan can be extended through recycling processes.</p>

- Q: This question asks for the cost of aluminum strip roofing, which is a type of metal roofing material.

- <p>The cost of aluminum strip roofing can vary significantly based on factors such as the quality of the aluminum, the complexity of the installation, and regional pricing. On average, the cost of aluminum strip roofing ranges from $6 to $12 per square foot for the materials alone. This does not include labor costs, which can add another $3 to $10 per square foot. It's important to get quotes from multiple contractors in your area to get an accurate estimate for your specific project. Prices can fluctuate, so it's best to check current market rates for the most up-to-date information.</p>

- Q: How much is the small aluminum belt excavator?

- There are many types of small tracked vehicles, but I don't know which one you want.

- Q: Can metal roofing materials be reused or recycled after they have been installed and used?

- <p>Yes, metal roofing materials can indeed be recycled after installation. Metal is one of the most recycled materials globally, and its recycling process is both efficient and environmentally friendly. When metal roofing reaches the end of its life, it can be collected, processed, and turned into new metal products, including new roofing materials. This recycling process helps conserve natural resources and reduces waste in landfills. The high recycled content of metal can also contribute to the sustainability and green credentials of construction projects.</p>

- Q: Explain how aluminum strips play a role in enhancing energy efficiency.

- <p>Aluminum strips contribute to energy efficiency primarily through their use in thermal insulation and reflective properties. In building construction, aluminum strips can be used to create airtight seals around windows and doors, reducing heat transfer and drafts, which in turn lowers the need for heating or cooling systems. Additionally, aluminum's reflective nature can be utilized in radiant barriers, which reflect heat away from buildings, reducing the energy required for cooling. In electrical applications, aluminum strips are used in high-efficiency transformers and electrical conductors due to their high conductivity and light weight, reducing energy loss during transmission. Overall, aluminum strips enhance energy efficiency by minimizing heat loss and improving the performance of energy systems.</p>

- Q: What are the potential drawbacks or negative aspects of utilizing aluminum strips as a material for exterior siding on a building?

- <p>Aluminum siding, while durable and lightweight, has several disadvantages. It can dent easily due to its softness, which may require frequent repairs. It also lacks insulating properties, leading to increased energy costs as it doesn't retain heat well. Additionally, aluminum siding can be noisy during heavy rain or hail, and it may expand and contract with temperature changes, causing warping or gaps. Furthermore, it can be more expensive than some other materials, and its reflective nature may lead to a less aesthetically pleasing appearance compared to other siding options.</p>

- Q: Can aluminum strips be utilized as materials for car body panels?

- <p>Yes, aluminum strips can be used for car body panels. Aluminum is known for its lightweight, high strength, and corrosion resistance, making it an ideal material for automotive applications. It offers better fuel efficiency due to reduced weight and improved safety due to its strength. Additionally, aluminum's recyclability makes it an environmentally friendly choice. However, it's important to note that aluminum requires different manufacturing techniques compared to traditional steel, and it may be more expensive.</p>

- Q: This question asks about the potential environmental effects resulting from the use of aluminum strips.

- <p>The environmental impacts of using aluminum strips include energy-intensive production processes that contribute to greenhouse gas emissions, potential water pollution from manufacturing, and solid waste generation. Aluminum production requires significant amounts of electricity, often from non-renewable sources, which can exacerbate climate change. Additionally, the mining and refining of bauxite, the primary source of aluminum, can lead to habitat destruction and water contamination. However, aluminum is also highly recyclable, and recycling reduces energy consumption and waste. The overall environmental impact depends on the balance between production, use, and recycling practices.</p>

Send your message to us

1/8 Aluminum Strips - Quality China Prepainted/Printed Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords