48'' ELBOW TEE BEND FLANGE CARBON STEEL FITTINGS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Detailed Description

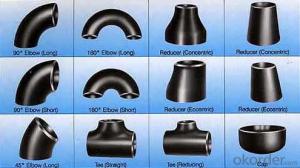

Products | pipe fittings elbows, bends,tees, reducers caps |

Size | 1/2" - 48" |

Wall thickness | Sch5-Sch160 XXS |

Standard | ANSI, ASME API5L, OCT, DIN and JIS, etc. |

we can also produce according to drawing and standards provided by customers. | |

Material | Carbon steel, alloy steel and stainless steel. |

We can produce according to materials appointed by consumers. | |

Packaging | Plywood Cases,plywood pallet, plastic bag or as customers requirement |

Surface Treatment | Shot blasted, rust-proof black oil |

Delivery Time | 10-60 days |

Quality | First grade |

Others | 1.Special design available according to your drawing. |

2.anti-corrosion and high-temperature resistant with black painting | |

3. All the production process are made under the ISO9001:2000 strictly. | |

4. A conformity rate of ex-factory inspection of products. |

Specifications

Ansi B16.9 WPB carbon steel pipe fitting elbow tee reducer

Size:Seamless 1/2"-24" Welded 1/2"-48"

ANSI B16.9 WPB carbon steel pipe fitting elbow tee reducer

1.Size: Seamless 1/2"-24" Welded 1/2"-48"

2. WT: SGP, STD, SCH40, SCH80, SCH100,SCH120,SCH160,XS,XXS

3. Material:

stainless steel Grade: 201,304,304L,316,316L,317,317L,904L,and etc

carbon steel Grade: WPB,GRB, Q235,16MN

Alloy steel: st35.8,st52,wp11,wp22,wp12 wp l6

4. Standard: ASTM/AISI/DIN/JIS

5. Type: Concentric and eccentric

6. Surface treatment: Transparent oil, rust-proof black oil

7. Applications range: Applications range: for use in the petroleum, smelting, foodstuff, power, papermaking, chemical, medical equipment,aviation, boiler heat exchanger, and other fields

8. Packing: wooden case or as per customers' requirement

- Q: How are steel pipes used in tunnel construction?

- Steel pipes are commonly used in tunnel construction for various purposes such as drainage, ventilation, and support. These pipes are installed to facilitate the removal of water from the tunnel, ensuring a dry working environment. They also serve as conduits for supplying fresh air and removing exhaust fumes. Additionally, steel pipes are utilized as structural supports, providing stability and reinforcement to the tunnel walls and ceilings.

- Q: How are steel pipes tested for mechanical strength?

- Steel pipes are tested for mechanical strength through various methods such as tensile testing, hydrostatic testing, and non-destructive testing. Tensile testing involves pulling the pipe until it breaks to measure its ultimate tensile strength. Hydrostatic testing involves pressurizing the pipe with water to check its ability to withstand high internal pressures. Non-destructive testing methods like ultrasonic testing or magnetic particle inspection are also used to detect any defects or weaknesses in the pipe without causing damage. These tests ensure that steel pipes are strong enough to withstand the required mechanical stresses.

- Q: What is the difference between steel pipes and PVC-O pipes?

- Steel pipes and PVC-O pipes differ in their material composition, strength, durability, and installation process. Steel pipes are made of steel, which makes them strong and suitable for high-pressure applications. However, they are prone to corrosion and require additional coating for protection. On the other hand, PVC-O pipes are made of a specially formulated, high-strength PVC material, which provides excellent resistance to corrosion, chemicals, and abrasion. PVC-O pipes are also lighter, easier to handle, and have a longer lifespan compared to steel pipes. Additionally, PVC-O pipes are installed using a jointing system, eliminating the need for welding or threading like steel pipes.

- Q: Will the steel tube dance?

- The steel tube dance tube has a rotating steel tube and a fixed steel tube, so that different types of steel pipe can be chosen according to the type of pipe dance performed by the dancer.

- Q: Can steel pipes be used for conveying compressed air?

- Indeed, compressed air can indeed be conveyed through steel pipes. In industrial settings, steel pipes find frequent use due to their ability to withstand high pressure and maintain durability. With their remarkable tensile strength, steel pipes prove capable of handling the immense pressures generated by compressed air systems. Furthermore, the resistance of steel pipes to corrosion becomes crucial when confronted with moisture within compressed air. Nevertheless, it remains vital to guarantee that the steel pipes are adequately sized and rated to meet the precise pressure and flow prerequisites of the compressed air system. Moreover, adhering to proper installation and maintenance practices becomes imperative to avert any potential leaks or failures.

- Q: What are the different methods of pipe insulation for steel pipes?

- There are several methods of pipe insulation for steel pipes, each with its own advantages and suitability for specific applications. Some of the commonly used methods include: 1. Fiberglass insulation: This is one of the most popular methods of pipe insulation. Fiberglass insulation is made of fine glass fibers and is available in various forms such as rolls, sheets, or pre-formed sections. It is lightweight, easy to install, and provides excellent thermal insulation properties. 2. Foam insulation: Foam insulation is another effective method for insulating steel pipes. It is available in different forms, including rigid foam boards or spray foam. Foam insulation is known for its high insulating value and its ability to seal gaps and cracks, providing enhanced energy efficiency. 3. Rubber insulation: Rubber insulation, commonly known as elastomeric insulation, is widely used for insulating steel pipes in HVAC systems. It is flexible, durable, and resistant to moisture, making it suitable for both indoor and outdoor applications. Rubber insulation also offers good thermal and acoustic insulation properties. 4. Polyethylene insulation: Polyethylene insulation is a cost-effective option for insulating steel pipes. It is available in different forms, such as foam tubes or molded sections, and is easy to install. Polyethylene insulation provides good thermal insulation, protects against condensation, and is resistant to water vapor diffusion. 5. Cellular glass insulation: Cellular glass insulation is a rigid insulation material made from crushed glass and a foaming agent. It is known for its exceptional thermal insulation properties, as well as its resistance to moisture, fire, and chemicals. Cellular glass insulation is commonly used in cryogenic and high-temperature applications. It is important to consider factors such as temperature, moisture conditions, and the specific requirements of the project when selecting the appropriate method of pipe insulation for steel pipes. Consulting with a professional or an insulation expert can help determine the best insulation method based on the specific needs and conditions of the project.

- Q: How to perform nondestructive inspection of steel tubes

- Radiographic inspection (RT)One of the earliest nondestructive testing methods is widely used in the inspection of internal defects of metals and non-metallic materials and products, with a history of at least 50 years. It has incomparable unique advantages, that is to test the correctness, reliability and intuition of the defects, and the ray film can be used for the analysis of defects and as a quality certificate archive. But this method also has the disadvantages of more complicated equipment and higher cost, and should pay attention to the protection of radiation.

- Q: What is the compressive strength of steel pipes?

- The compressive strength of steel pipes can vary depending on the specific grade and manufacturing process, but it is generally high. On average, steel pipes have a compressive strength ranging from 60,000 to 120,000 pounds per square inch (psi).

- Q: What is the role of steel pipes in sewage systems?

- Steel pipes are commonly used in sewage systems as they provide durability, strength, and resistance to corrosion. They serve the crucial role of transporting wastewater, sewage, and other fluids from buildings to treatment facilities or disposal sites. Steel pipes are able to withstand the high pressure and gravity flow of sewage, ensuring the safe and efficient conveyance of waste materials.

- Q: Are steel pipes suitable for use in hydropower plants?

- Yes, steel pipes are suitable for use in hydropower plants. Steel pipes offer excellent durability, strength, and resistance to corrosion, making them ideal for transporting water or other fluids in hydropower systems. Additionally, steel pipes can withstand high pressure and provide efficient flow rates, ensuring reliable and efficient operation of the hydropower plant.

Send your message to us

48'' ELBOW TEE BEND FLANGE CARBON STEEL FITTINGS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords