48'' 32'' ELBOW TEE BEND FLANGE CARBON STEEL FITTINGS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Detailed Description

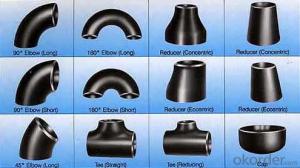

Products | pipe fittings elbows, bends,tees, reducers caps |

Size | 1/2" - 48" |

Wall thickness | Sch5-Sch160 XXS |

Standard | ANSI, ASME API5L, OCT, DIN and JIS, etc. |

we can also produce according to drawing and standards provided by customers. | |

Material | Carbon steel, alloy steel and stainless steel. |

We can produce according to materials appointed by consumers. | |

Packaging | Plywood Cases,plywood pallet, plastic bag or as customers requirement |

Surface Treatment | Shot blasted, rust-proof black oil |

Delivery Time | 10-60 days |

Quality | First grade |

Others | 1.Special design available according to your drawing. |

2.anti-corrosion and high-temperature resistant with black painting | |

3. All the production process are made under the ISO9001:2000 strictly. | |

4. A conformity rate of ex-factory inspection of products. |

Specifications

Ansi B16.9 WPB carbon steel pipe fitting elbow tee reducer

Size:Seamless 1/2"-24" Welded 1/2"-48"

ANSI B16.9 WPB carbon steel pipe fitting elbow tee reducer

1.Size: Seamless 1/2"-24" Welded 1/2"-48"

2. WT: SGP, STD, SCH40, SCH80, SCH100,SCH120,SCH160,XS,XXS

3. Material:

stainless steel Grade: 201,304,304L,316,316L,317,317L,904L,and etc

carbon steel Grade: WPB,GRB, Q235,16MN

Alloy steel: st35.8,st52,wp11,wp22,wp12 wp l6

4. Standard: ASTM/AISI/DIN/JIS

5. Type: Concentric and eccentric

6. Surface treatment: Transparent oil, rust-proof black oil

7. Applications range: Applications range: for use in the petroleum, smelting, foodstuff, power, papermaking, chemical, medical equipment,aviation, boiler heat exchanger, and other fields

8. Packing: wooden case or as per customers' requirement

- Q: Can steel pipes be used for the construction of high-rise buildings?

- Yes, steel pipes can be used for the construction of high-rise buildings. Steel pipes are commonly used in the construction industry due to their strength, durability, and ability to withstand high pressure and heavy loads. They are often used in the structural framework of high-rise buildings to provide structural support and stability. Additionally, steel pipes can be easily fabricated and installed, making them a suitable choice for constructing tall and complex structures.

- Q: What are the different methods of repairing damaged steel pipes?

- There are several methods of repairing damaged steel pipes, including welding, epoxy lining, pipe bursting, and pipe relining. Welding involves joining the damaged sections of the pipe together using heat, while epoxy lining involves applying a protective coating to the inner surface of the pipe. Pipe bursting involves replacing the damaged pipe with a new one by pulling it through the existing pipe, and pipe relining involves inserting a new liner into the damaged pipe to create a new, seamless pipe within the existing one. The choice of method depends on factors such as the extent of damage, accessibility, and cost-effectiveness.

- Q: Can steel pipes be used for underwater applications?

- Yes, steel pipes can be used for underwater applications. Steel pipes are known for their durability and corrosion resistance, making them suitable for various underwater purposes such as offshore oil drilling, underwater construction, and marine transportation. Additionally, steel pipes can withstand the high pressure and harsh environmental conditions present underwater, making them a reliable choice for such applications.

- Q: How are steel pipes used in the automotive industry?

- Steel pipes are commonly used in the automotive industry for various applications such as exhaust systems, fuel lines, and structural components. They provide durability, strength, and resistance to high temperatures, making them ideal for carrying exhaust gases, fuel, and providing support to the vehicle's frame.

- Q: How are steel pipes protected against ultraviolet (UV) radiation?

- Steel pipes are typically protected against ultraviolet (UV) radiation through the application of specialized coatings or paints that act as a barrier, preventing direct exposure of the steel to UV rays. These coatings are designed to withstand UV degradation, prevent corrosion, and extend the lifespan of the pipes.

- Q: What are the common standards and specifications for steel pipes?

- The common standards and specifications for steel pipes include ASTM A53, ASTM A106, API 5L, and ISO 3183. These standards outline the requirements for the manufacturing, dimensions, and mechanical properties of steel pipes used in various industries such as oil and gas, construction, and transportation. Additionally, specific applications may have their own standards and specifications that need to be met for quality and safety purposes.

- Q: What's the difference between steel pipe and pipe fittings?

- Pipe fittings: parts that connect pipes to pipes. According to the connection method can be divided into socket type pipe fittings, threaded fittings, flange pipe fittings and welding pipe fittings four kinds. Multipurpose; made of the same material as pipes. Elbow (elbow), flange, three pipe and four pipe (crosshead) and reducer (reducer) etc.. Elbow for pipeline corner; flange for the pipe and pipe interconnected parts, connected to the pipe end, three pipe for three pipe collection; four pipe for four tubes together place; for two pipes of different diameters connected to different diameter pipe.

- Q: Are steel pipes suitable for use in acidic environments?

- Steel pipes may not be suitable for use in acidic environments because they can corrode and degrade when exposed to acids, leading to potential leaks and structural issues.

- Q: What is the role of steel pipe manufacturers in sustainable development?

- Steel pipe manufacturers play a crucial role in sustainable development by promoting environmental responsibility, resource conservation, and reducing carbon emissions. They contribute to sustainable development by adopting cleaner production techniques, recycling waste materials, and investing in research and development to improve energy efficiency. Additionally, they prioritize worker safety and adhere to stringent quality standards, ensuring the durability and longevity of their products, which further supports sustainable construction practices.

- Q: How are steel pipes classified based on their wall thickness?

- Steel pipes are classified based on their wall thickness into three categories: standard weight, extra-strong, and double extra-strong.

Send your message to us

48'' 32'' ELBOW TEE BEND FLANGE CARBON STEEL FITTINGS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords