45 Gsm Fiberglass Mesh Roll Reinforcement 180gram

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Mesh Roll 180gram Reinforcement

Fiberglass Mesh Roll 180gram Reinforcement is mainly alkali-resistant fiberglass fabric, use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. It's an ideal engineering material in construction and decoration industry.

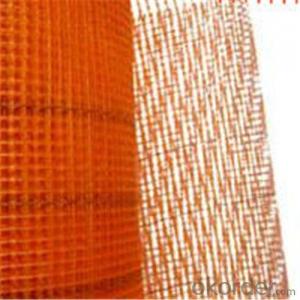

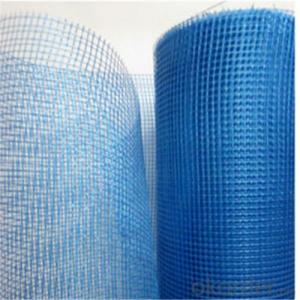

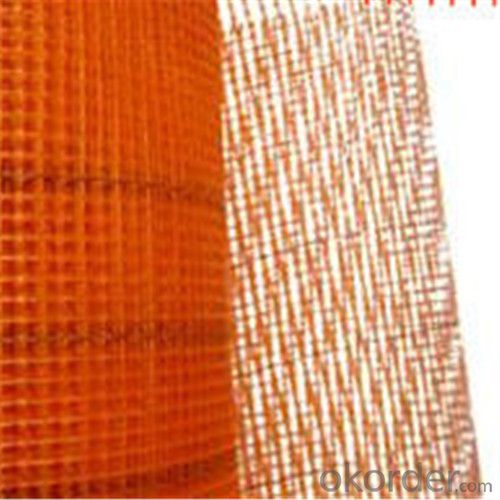

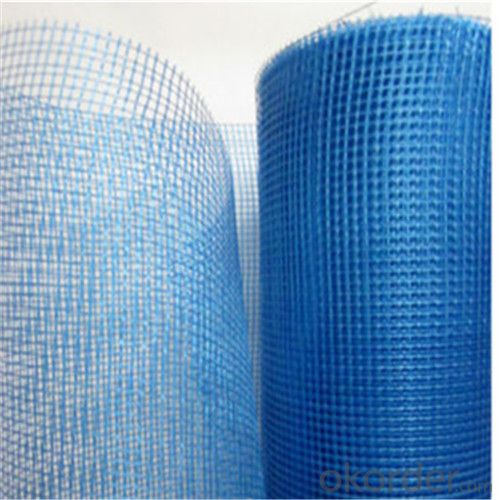

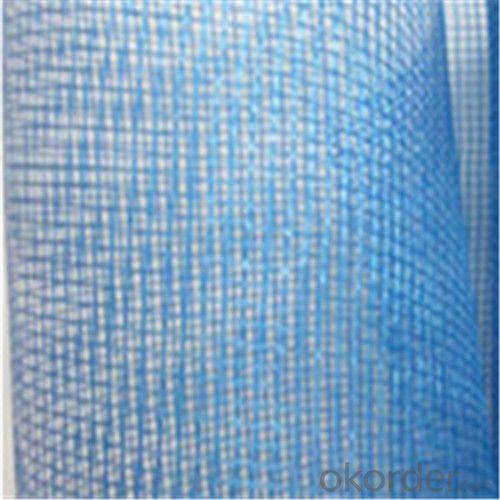

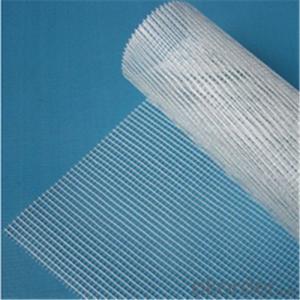

Image of Fiberglass Mesh Roll 180gram Reinforcement

Quick Detail of Fiberglass Mesh Roll 180gram Reinforcement

FOB Price of Fiberglass Mesh Roll 180gram Reinforcement: US $0.21 – 0.32 / Square Meter

MOQ of Fiberglass Mesh Roll 180gram Reinforcement: 5000 Square Meters

Supply Ability of Fiberglass Mesh Roll 180gram Reinforcement: 2000000 Square Meters per Month

Loading Port of Fiberglass Mesh Roll 180gram Reinforcement: CHINA MAIN PORT

Payment Terms of Fiberglass Mesh Roll 180gram Reinforcement: L/C, T/T

Specifications of Fiberglass Mesh Roll 180gram Reinforcement

Fiberglass Mesh Roll 180gram Reinforcement Place of Origin: China (Mainland)

Fiberglass Mesh Roll 180gram Reinforcement Brand Name: CMAX

Fiberglass Mesh Roll 180gram Reinforcement Application: Wall Material, Marble Slab Reinforcement

Fiberglass Mesh Roll 180gram Reinforcement Width: 1M-2M

Fiberglass Mesh Roll 180gram Reinforcement Size: 5*5/ INCH, 4*4/ INCH, 4*5/ INCH

Fiberglass Mesh Roll 180gram Reinforcement Weight: 40gsm to 200gsm

Fiberglass Mesh Roll 180gram Reinforcement Length/ roll: 50m-100m, Special spec can be customized

Fiberglass Mesh Roll 180gram Reinforcement Weave Type: Leno, Plain Woven

Fiberglass Mesh Roll 180gram Reinforcement Yarn Type: C-Glass, E-Glass

Fiberglass Mesh Roll 180gram Reinforcement Alkali Content: Medium Alkali

Fiberglass Mesh Roll 180gram Reinforcement Standing Temperature: 500℃

Packing and Delivery of Fiberglass Mesh Roll 180gram Reinforcement

Package: Each Fiberglass Mesh Roll 180gram Reinforcement roll is wrapped in a shrink bag, then put into containers

Packing Volumes: : 45000-50000m2/ 20FCL, 110000m2/ 40HQ, etc..

Delivery: About 15 days after confirming the order of Fiberglass Mesh Roll 180gram Reinforcement

Application/Usage of Fiberglass Mesh Roll 180gram Reinforcement

A. Wall reinforced material:

Fiberglass wall mesh, GRC wall panels,

EPS insulation with the wall board,

Gypsum board, Bitumen etc

B. Reinforced cement products.

C. Used for Granite, mosaic, marble back mesh etc.

D. Fabric waterproof membrane, asphalt roofing.

E. Framework material for reinforced plastics, rubber products,.

F. Fire board.

G. Grinding wheel base fabric.

H. Road surface geogrid.

I. Construction caulking tape etc.

FAQ of Fiberglass Mesh Roll 180gram Reinforcement

Q: What is Fiberglass Mesh?

Coated Alkali-resistant Fiberglass Mesh cloth is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the main application of Fiberglass Mesh Roll 180gram Reinforcement?

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement

Electrical heating mats

Marble slab reinforcement / Mosaic carrier

Asphalt reinforcement (roof water-proof)

Reinforced lightweight construction boards

Q: What is the storage of Fiberglass Mesh Roll 180gram Reinforcement?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Fiberglass Mesh Roll 180gram Reinforcement?

Four years under normal weather conditions and use

Q: What is the Advantage of Fiberglass Mesh Roll 180gram Reinforcement?

A. Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

B. Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

C. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

D. Strength retention rate> 90%, elongation<1%, the durability of more than 50 years.

E. Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property.

F. Good impact resistance and not easy to be teared

- Q: The household is screened glass fiber gauze or stainless steel gauze.

- Of course, the glass fiber network is good, the warp and weft bonding. Yarn mesh size is constant, suitable for cleaning,

- Q: Air purifier filter, activated carbon or glass fiber good?

- The HEPA screen made of glass fiber is generally accepted to achieve high efficiency. Because of the high requirement of glass fiber in making technology, the quality of products is low.

- Q: How to choose glass fiber filter cartridge

- Next is the end cover and the support net, the end cover should use 0.7-0.8 millimeter thick high quality plate production, in order to increase the overall intensity of the canister. Support network can not be careless, the same should choose 0.8 mm thick diamond support network, to ensure that the filter cartridge will not be blowing in the air will not be deflated.

- Q: What is the performance of wall mesh?

- Wall mesh is also known as glass fiber wall mesh, which is made from C-fiberglass yarn and E-fiberglass yarn on the basis of glass fiber mesh, and is a new type of alkali resistant product by coating acrylic?acid copolymer and drying. Wall mesh is characterized by structural stability, high strength, good alkali resistance, anticorrosion and cracking, reinforcement is the best, and the construction is simple and easy to operate. Wall Mesh is mainly used in cement, gypsum, walls, buildings and other structures for the reinforcement and cracking of inside and outside surface, which is a new type of construction materials for external wall thermal insulation projects.

- Q: What additive does alkali resistant glass fiber gridding cloth has?

- Ore melting status by purification of lower alkali content in wire drawing glass fiber grid cloth weaving to deal with

- Q: Waht should be noticed when laying fiber mesh plaster in inner wall? Is it not allowed to lap while laying mesh? Where it is 10cm in doorframe should be paved.

- What is very general is that mesh lapping is not enough in these parts, and tips are treated improperly or palster mortar is not sealed closely, thus causing rain leakage and even thermal bridges. In recent years, domestic completion of the new building has many wall leakage in windowsill, gutter spout funnels, cornice,etc. due to poor thermal insulation construction. And to stop leakage is very difficult because the leakage point is not easy to be found. 4. Due to unfirm pasting of polystyrene board, there are more and more quality problems. The most serious situation is the falling-of accident of polyphenyl board, and the reason is: a. Poor quality of construction and insufficient cement pasting area cause falling off; b. mishandling of the old wall; 5. Using unqualified materials. a. Use neutral or low-alkali fiberglass mesh. b. The volume-weight of polystyrene board is not enough. Its compressive strength and shear strength are low. c. No use of polymer cement bonding. d. Cement strength level is not enough. Solutions (a) the choice of adhesive mortar

- Q: Can the internal wall plastering be made of fiberglass mesh? The wire mesh is in contact with each other

- The interior wall is usually made of paint, so it is OK to use fiberglass mesh for the anti cracking net.

- Q: What is the tensile strength of glass fiber?

- Silica is the main raw material made of silica on the earth reserves is great. Silica is the main raw material for the main raw material is made of glass stones. The silicon content of different rocks are different. In our life of these materials is the most common.

- Q: The introduction to alkali-resistant glass fiber mesh cloth

- Alkali-resistant fiberglass mesh alkali or alkali glass fiber woven fabric is based by alkali-resistant coating, the product is excellent in strength, adhesion, docile nature, positioning, which is widely used in enhanced wall and thermal insulation and waterproof of external wall.

- Q: Is it possible to crack the fiberglass net for the exterior wall painting?

- It's the barbed wire or the glass fiber net, which is usually attached to the wall and the beam, where the wall meets the post, because they are easy to crack

Send your message to us

45 Gsm Fiberglass Mesh Roll Reinforcement 180gram

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords