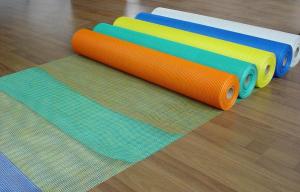

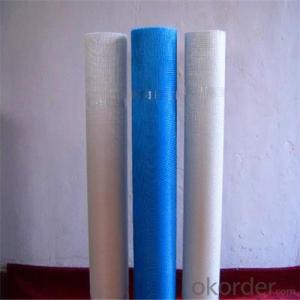

Fine Fiberglass Mesh Cloth 75g 5*5mm

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 m2 m²

- Supply Capability:

- 10*40HQ/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

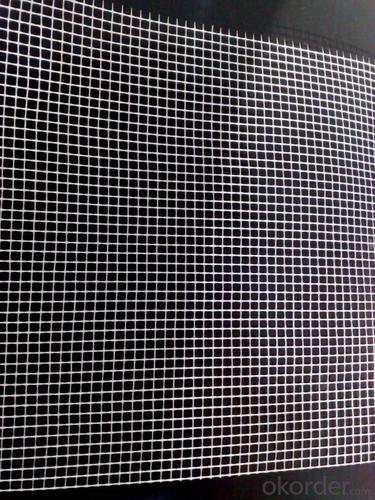

Specifications of Fiberglass Mesh Cloth 75g 5*5mm

Coated Alkali-resistant fiberglass mesh cloth is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron. The resin used for the surface treatment ensures the property of alkali-resistance and increases the mechanical durability that is required by the construction industry.

Usage/Applications of Fiberglass Mesh Cloth 75g 5*5mm

1.External Thermo Insulating Composite System (ETICS) & External Insulating Finish System (EIFS)

2.External and internal plaster reinforcement

3.Electrical heating mats

4.Marble Slab Reinforcement / Mosaic Carrier

5.Asphalt reinforcement (roof water-proof)

6.Reinforced lightweight construction boards

Packaging & Delivery of Fiberglass Mesh Cloth 75g 5*5mm

Each roll is wrapped in a shrink film or plastic bag. Then rolls are packed into cartons or pallets.

Production Line of Fiberglass Mesh Cloth 75g 5*5mm

- Q: What is the difference of the interior wall mesh and external wall mesh?

- The main distinction between the external wall thermal insulation Mesh and the interior wall Mesh is the different raw material of them. The external walls Mesh are generally with the raw material of alkali or alkali-free mesh, and then after multideck coating , it becomes an alkali resistance Mesh. This products are with a very good stability and a strong tensil strength which is easy for the construction.

- Q: What are the requirements for wall insulation fiberglass mesh?

- Article 4.0.6 A test for alkali resistant tensile breaking strength shall be in accordance with provisions A12.2 of this Regulation appendix, fiberglass mesh alkali-resistant tensile breaking strength and alkali-resistant tensile breaking strength retention rate should be in accordance with regulations in table 4.0 .6. Table 4.0.6 Glass fiber mesh performance requirements: test items: alkali tensile breaking strength N / 50mm; alkali tensile breaking strength retention % . warp-wise, weft, warp-wise,weft. performance requirements: fiberglass mesh ≥750≥50; alkali-resistant fiberglass mesh ≥1000≥75.

- Q: What do medium soft and medium hard mean in fiberglass mesh?

- The softer it is, the better material is. Fiberglass mesh is based on glass fiber woven fabric and formed by alkali-resistant coating.

- Q: What is the function of exterior walls insulation alkali-resistant mesh?

- external wall thermal insulation mesh is made from C-fiberglass yarn and E-fiberglass yarn on the basis of glass fiber mesh, and is a new type of alkali resistant product by coating acrylic?acid copolymer and drying. The product is characterized by structural stability, high strength, good alkali resistance, anticorrosion and cracking, reinforcement is the best, and the construction is simple and easy to operate. And it is mainly used in cement, gypsum, walls, buildings and other structures for the reinforcement and cracking of inside and outside surface, which is a new type of construction materials for external wall thermal insulation projects.

- Q: What is specification for alkali-resistant fiberglass mesh?

- Interior wall thermal insulation fiberglass mesh: Interior wall insulation alkali-resistant fiberglass mesh apots alkali or alkali-resistant fiberglass mesh as substrate and then coated with modified acrylate copolymer adhesive solution. It is characterized by lightweight, high-strength, heat resistance, alkali-resistance, waterproof, corrosion resistance, resistance to cracking, and dimensional stability. It can effectively avoid tension contraction of the whole surface of floated coat and crack caused by an external force, thin mesh is often used in wall renovation and interior wall insulation.

- Q: How to layout alkali resistant glass fiber grid cloth?

- When seeting walls, gridding cloth can be cut along with the the dividing joint. Reason: the gridding cloth is used for crack resistance and the dividing joint can help reduce wall stress, therefore, it can be a way to reduce crack. Cutting is ok as long as the cardinal plane of base is not affected.

- Q: Why should the construction of carbon fiber mesh be carried out at a temperature of over 5?

- Glass fiber mesh fabric is based on medium alkali or non alkali glass fiber woven fabric and is made of alkali resistant coating. The product has high strength, good paste, docile, excellent positioning, broad using in wall consolidation, wall insulation, roofing and other aspects should be enhanced for, may also wish to cement, plastics, asphalt, marble, mosaic and other wall materials, the building industry is ideal engineering material.

- Q: For puttying in decoration, anti-cracking fiberglass mesh or dacron cloth is widely used on walls. What are the correct constrcution order and method?

- If it is not sticked firmly, use white latex strip to attach bar-type anti-cracking cloth at the seams. Brush some white latex on anti-cracking cloth again.

- Q: What is the packet processing method of external wall thermal insulation mesh?

- 1. Before pasting polystyrene board, insulation layer on the cut-off portion should do a flanging mesh, the flanging parts spread on 70mm wide and 2mm thick polymer mortar, and quickly press an edge of 70mm mesh into polymer binding mortal with steel until gushy polymer binding mortal covers the mesh without leakage. 2. The remaining part is of packed for standby application, the length of throwing parts bypassing the end plate of the exposed surface is not less than 100mm, the pasted mesh should take flip or cover and product protection measures.

- Q: What are the types of glass fiber gridding cloth?

- Specifications for gridding cloth for external walls: 70-160/g. Gridding cloth for external walls is featured by low cost, messy layout, high resistance to alkali, corrosion and cracking, easy construction. It is used for strengthening cement plaster wall.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 2009 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | about 300 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 4000m2 |

| No. of Production Lines | 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | 0.13 usd/m2-0.28usd/m2 |

Send your message to us

Fine Fiberglass Mesh Cloth 75g 5*5mm

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 m2 m²

- Supply Capability:

- 10*40HQ/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords