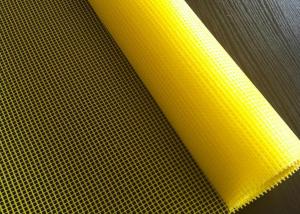

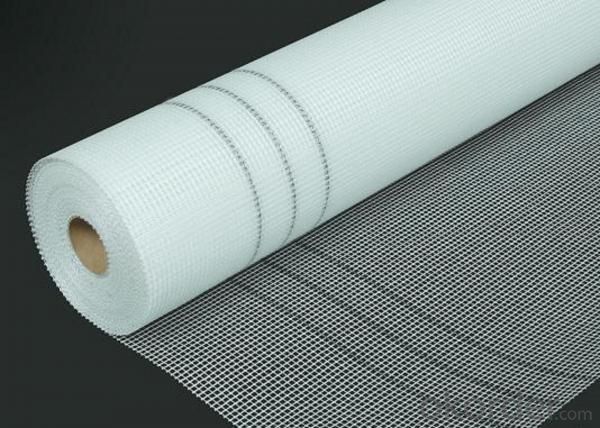

Ptfe Coated Fiberglass Mesh 75g 4*4mm

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 M2 m²

- Supply Capability:

- 10*40HQ/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Fiberglass Mesh 75g 4*4mm

Coated Alkali-resistant fiberglass mesh cloth is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface.

The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

The resin used for the surface treatment ensures the property of alkali-resistance and increases the mechanical durability that is required by the construction industry.

Usage/Applications of Fiberglass Mesh 75g 4*4mm

1.External Thermo Insulating Composite System (ETICS) & External Insulating Finish System (EIFS)

2.External and internal plaster reinforcement

3.Electrical heating mats

4.Marble Slab Reinforcement / Mosaic Carrier

5.Asphalt reinforcement (roof water-proof)

6.Reinforced lightweight construction boards

Packaging & Delivery of Fiberglass Mesh 75g 4*4mm

Each roll is wrapped in a shrink film or plastic bag. Then rolls are packed into cartons or pallets.

Production Line of Fiberglass Mesh 75g/m2

- Q: What is the function of the cracking resistant mortar Mesh?

- The cracking resistant mortar is a bag of ready-mixed material, it can be used for the construction just after stirring with the water. The aggregate of the cracking resistant mortar is very rough, so it is not easy to crack. In addition to the mixture of the wood fiber and other mortar admixture, it can form a three-dimensional and multi-dimensional mesh structure. It can relieve the stress flexibilely so as to remove the crack brought by the temperature difference.

- Q: What steps should be taken to make wall fiberglass mesh?

- 1. Wall should be kept clean and dry. 2. Paste mesh at cracks and press tightly. 3. Confirm the gap has been covered by mesh, then cut useless mesh with a knife, the last step is to brush on mortar. 4. Leave it dry alone, then polish lightly. 5. Fill it with enough coat to make the surface smooth. 6. Remove extra mesh. Then, pay attention to that all the cracks have been properly repaired, decorate around with composite material to make it clean as new.

- Q: Are fiber glass lightweight composites?

- Glass fiber itself is an inorganic non-metallic material, glass fiber as the base material of composite materials, and resin with the formation of composite materials, alone, glass fiber is a composite material unscientific.

- Q: As for the latitudinal tension and longitudinal tension of alkali resistant glass fiber gridding cloth, which is larger?

- latitudinal

- Q: How to layout alkali resistant glass fiber grid cloth?

- When seeting walls, gridding cloth can be cut along with the the dividing joint. Reason: the gridding cloth is used for crack resistance and the dividing joint can help reduce wall stress, therefore, it can be a way to reduce crack. Cutting is ok as long as the cardinal plane of base is not affected.

- Q: Can glass fiber gridding cloth waste be recycled? If can, then what is is?

- The acrylic in grid cloth can produce pungent smell and cause serious soil pollution after high temperature, which proves the environmental protection of glass fiber. It may cause serious air and soil pollution and contain harmful substance to respiratory system. And the core material of grid ding cloth is flame retardant and cannot be burnt.

- Q: What is the difference between the glass fiber mesh fabric with inner and outer wall insulation?

- Glass fiber cloth Chinese are usually used with the external wall insulation system, will not have a "cold bridge and bridge", has praised the outstanding architectural energy-saving effect, which has been in the construction industry.

- Q: What kinds of industrial cloth are there? What kind of cloths and procedures are employed?

- I do not know what you mean by so-called industrial cloth. In fact, there are several meanings about cloth. According to the material of the fabric, it is then referred to the textile fibers. Despite the wide variety of textile fibers, but basically it can be divided into natural fiber and chemical fiber : 1. natural fiber refers to textile fibers that have been existing in the natural world, or directly obtained textile fibers from cultured animal . 2. Chemical fiber is a kind of textile fibers which make natural or synthetic polymers as raw material, and manufactured through a certain of method. 3 Artificial fiber refers to processed fibers whihch capitalize on the natural polymer manmade fibers (such as wood, bagasse or animal fibers, etc.) as raw material. 4. The synthetic fibers, with oil, coal, natural gas and a number of agricultural products as raw materials, are formed by synthetic polymer spinning. When mentioning procedures, they are usually secrets unrevealed!

- Q: In the decoration, is it to paste the double mesh on the painting wall surface?

- It is generally single-layer.

- Q: How to tell the quality of mesh cloth?

- The standard and fine quality mesh cloth has good alkali resistance in the selection of materials. The advantage is that all of the alkali resistance and high tensile resistance of the warp and weftThe fence is made of platinum. The woven emulsion is made of glass fiber as base material. The product has good hand feeling and docile construction is good, greatly reduce the spreadAmount of face mortar.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 2009 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | about 300 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 4000m2 |

| No. of Production Lines | 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | 0.13 usd/m2-0.28usd/m2 |

Send your message to us

Ptfe Coated Fiberglass Mesh 75g 4*4mm

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 M2 m²

- Supply Capability:

- 10*40HQ/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords