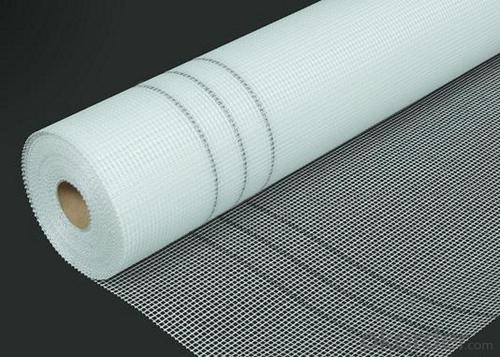

Home Depot Fiberglass Mesh Tape - 145g, 3 Black Lines

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our advantage:

1. Have CE, ITB, ETAG004, ISO9001 certificates

2. One of the biggest producers in China

3. Good quality and best service

Fiberglass mesh is woven by fiberglass yarn as its basis mesh, and then coated by alkaline resistant latex. It has fine alkaline-resistant, high strength, etc. As an ideal engineering material in construction, it is mainly used to reinforce cement, stone, wall materials, roofing, and gypsum and so on.

Feature:

1) Width: From 200mm To 2500mm.

2) Roll length: 50m,100m,300m as per the customer require.

3) Mainly Mesh Size: From 2.5 x 2.5mm To 10 x 10mm.

4) Mainly density from: 60g/m2 to 500g/m2

5) Color: white, blue, orange ets, all kinds could available

6)Packing: Inner packing: Shrink wrap Outer packing: Carton and Pallet

7)Logo printed on the mesh: available

8)Hard or soft mesh are both available

Large production capacity.

We can supply 6 million -8 million square meter one month for fiberglass mesh.

We can supply 2 million -4 million square meter one month for self adhesive tape

Certificates to guarantee quality.

Passed in ISO9001: 2000 certificate, IQ net, China National test, only our factory was passed Europe ETAG certificate in China.

Supply fiberglass mesh like strong or flexible mesh, soft or hard, fireproof, different color and sizes: From 30G/M2 to 500G/M2.

- Q: What is the best kind of external wall mesh.

- Good repeatability, green environmental friendly glass fibric mesh is also called glass?fiber geotextile, it has the effective coverage of old and new wall defects, insulation, to ensure a balanced surface structure and color.

- Q: When doing exterior wall insulation, should you first put mesh cloth, and then play the anchor bolt, or first play the anchor bolt, then mesh cloth, why?

- If you hit the anchor bolt first, it can only be the part of the fixed insulation board, that is, the point pressure. When the mesh is first laid, then the anchor bolt is equal to the anchor bolt, and the fixed force is applied directly to the grid cloth, and is fixed as a whole. This point on the insulation material, fiber type insulation materials more directly reflect, such as rock wool

- Q: Are fiber glass lightweight composites?

- Glass fiber itself is an inorganic non-metallic material, glass fiber as the base material of composite materials, and resin with the formation of composite materials, alone, glass fiber is a composite material unscientific.

- Q: What's the gridding cloth? What's the application of them?

- With glass fiber woven fabric as base material, gridding cloth is processed with high alkali emulsion. GRC products are featured by high strength, lasting alkali resistance. Cement and concrete products, GRC wallboard and GRC components.

- Q: Can the internal wall plastering be made of fiberglass mesh? The wire mesh is in contact with each other

- Plaster usually galvanized wire mesh, relatively strong. The price is not the same.

- Q: What is the specification of external wall thermal insulation mesh

- Mesh size: 5x5mm, 4x4mm gram weight: 80g160g / m2 Width: 1000mm2000mm length: 50m, 100m or 200m Color: White (standard), blue, green or other colors Packing: According to customer requirements 3, GRC enhanced mesh product specifications: Mesh size: 8x8mm, 10x10mm, 12x12mm gram weight: About 125g / m2 width: 600mm, 900mm, 1000mm length: 50m or 100m Color: White (standard), yellow, green or other colors Packing: According to customer requirements

- Q: Rock wool board insulation, why add two layers of glass fiber network, and XPS is a layer?

- Yes, that's right. Do two layers of mesh cloth to increase the thickness of the surface layer, improve the anti cracking performance and prevent the rainwater from seeping in. We are now doing a rock wool insulation is done: rock wool board full sticky paste, wire mesh hanging in the 50*50 rock wool board, and fixed with anchor bolt, with glazed hollow bead insulation mortar leveling (20mm thick) coated on the surface of the mortar, the middle laying a layer of mesh cloth. The advantage of this method is that the surface smoothness is good, and the anti cracking effect is good. It can prevent the rainwater from entering and make the rock wool soak.

- Q: does the anti-cracking net between the different matrixof the interior wall plastering can use the glass?fiber alkali resistant mesh? the steel mesh are hanging between the contacts.

- Interior finishing layer is generally painted coat, the coat finishing consturction anti-crack net is alkali resistant glass?fiber net, and the veneer of the facing brick consturction anti-crack net is galvanized steel wire netting.due to the consideration of the safety of the engineering and the wall anti-crack net use, the anti-crack net is using the glass?fiber mesh.

- Q: what's the thermal insulation effect of the self-adhesion thermal insulation reflection of light aluminium foil glass fiber fabric mesh.

- However, aluminum foil and heat insulation cloth fabric is good in general, the aluminum foil is mainly to solve the radiant heat, with the use of the cotton to reach the best effect.

- Q: What kind of fiberglass mesh is needed to touch the outer wall?

- The two functions are different, because one is used to heat the interior wall, and the other is the exterior wall heat preservation net

Send your message to us

Home Depot Fiberglass Mesh Tape - 145g, 3 Black Lines

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords