400mm HP Grade Graphite Electrode for Sale for Foundry Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Graphite Electrode Description

We has complete production lines, which include raw material mixing, forming line, baking line, impregnation equipment, graphitization line and machining and shaping line. Our annual capacity is 60,0000tons.

2.Main Features of the Graphite Electrode

(1) Direct manufacturer, office based on Beijing.

(2) Competitive price with prior quality

(3) High density with low resistivity

(4) High carbon content

(5) RP HD HP UHP Grade for your reference

3.Graphite Electrode Images

Packaging: Wooden Pallets, well packaged.

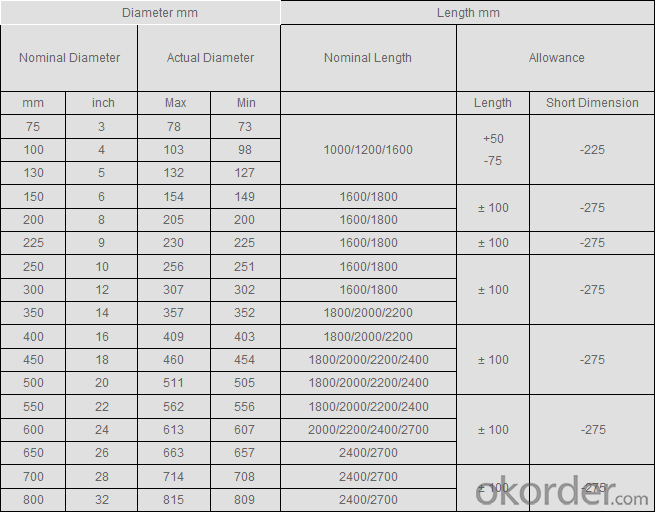

4.Graphite Electrode Specification

5.FAQ

(1) How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; we resolutely put an end to unqualified products material flowing into the market. At the same time, we will provide necessary follow-up service assurance. We welcome you to visit our mill.

(2) MOQ

For trial order, we accept 20 MT.

(3) Payment term

20% deposit, balance against the BL copy。

(4) How long can we receive the product after purchase?

We have large quantity in stock, and we could machine it to the size you need, so the delivery time is around 25 days after receiving your deposit.

- Q: Is graphite electrode good for foreign trade?

- I do graphite electrode production, but also do trade. The profit depends on the price you talked about. It should be around 2000.

- Q: Classification, uses and manufacturers of graphite electrodes

- Classification of graphite electrodes:(1) common power graphite electrode (RP), (2) high power graphite electrode (HP), (3) quasi ultra high power graphite electrode (SHP), (4) ultra high power graphite electrode (UHP) Note: poly carbon classification method

- Q: The use of graphite as an electrode in alumina electrolysis

- Graphite acts as an electrode:The electrical conductivity of graphite, the electrode itself must be electrically conductive;When graphite acts as an anode, it acts as a reducing agent and displaces an element of aluminum in a chemical reaction;Graphite is cheap and cost saving.

- Q: Will the concentration of electrolytic sodium sulfite be increased with graphite as electrode?

- Can't。 During electrolysis, there is depletion of sulfite ions.

- Q: Is the anode of electrolytic water suitable for ordinary titanium wires?

- Graphite firstFirst of all, the titanium electrode is usually not pure titanium, it should be titanium with a metal oxide coating. Secondly, the advantages of the titanium electrode is mainly to save electricity, the corrosion resistance of carbon is much stronger than that of industrial production, if the meaning is relatively large, but it is still in laboratory experiments, electrolysis of water, not what meaning.

- Q: In EDM, the electrodes are made of graphite and copper. Please tell us the difference between them

- Graphite is characterized by coarse particles, fine particles and ultrafine particlesFor different processing, you can choose different particles, the smaller the particle size, the higher the accuracyCopper has good conductivity and thermal conductivity and is used in many occasionsBut there are many factors to consider in the choice between the two

- Q: The graphite electrode made by the machining center adopts cooling method, which is water cooled, oil cooled and blow cold. Which is good?

- In addition, the infiltration of water on graphite is not good, can not get the effect of dust removal. Now there are special graphite machine, sealing system. Air-cooled can be used, after all, the best air-cooled.

- Q: Graphite electrode press device

- Graphite electrode is mainly in the petroleum coke and needle coke, coal tar pitch as binder, calcination, mixing, kneading, pressing, baking and graphitization, and made the processing machine, is a conductor in an electric arc furnace to form arc release electricity for heating and melting of the charge, according to the quality index level, can is divided into ordinary power, high power and ultra high power.

- Q: What do carbon products include?

- High power electrode and ultra high power electrode. The carbon block can be divided into blast furnace carbon block, aluminum carbon block and electric furnace block. Carbon products can be divided into carbon products, graphite products, carbon fibers and graphite fibers according to the depth of processing. Carbon products can be divided into graphite products, carbon products, carbon fibers and special graphite products according to the raw materials and the production process. Carbon products according to their ash content, and can be divided into multi gray products and less ash products (including ash below l%).

- Q: How about graphite electrode high-temperature oxidation resistant coating?

- The utilization ratio of graphite energy can reach more than 95%. Many kinds of antioxidant paint, it is recommended to directly find their technicians, you can give professional advice, according to the actual situation, the reasonable use of high-temperature oxidation resistant paint.

Send your message to us

400mm HP Grade Graphite Electrode for Sale for Foundry Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches